Method for manufacturing seamless copper pipe and rod core used for cold rolling mill

A manufacturing method and technology of a cold-rolled pipe mill, applied in the direction of manufacturing tools, pipes, rigid pipes, etc., can solve problems such as waste of manpower and material resources, limited length of copper pipes, low efficiency, etc., and achieve copper saving and qualified rate of finished products The effect of improving and reducing the number of people

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0014] A method for manufacturing a seamless copper tube, comprising the steps of: using high-purity cathode copper Cu-CATH-1 to cast a solid ingot with a diameter of 185 mm and a length of 500 mm through a 1T semi-continuous casting unit; heating the solid ingot with gas The furnace is heated to 850°C, and a thick-walled tube billet with an outer diameter of 80mm and a wall thickness of 11mm is extruded on a 1600T horizontal double-action water-sealed extruder; A copper tube with a diameter of 40mm and a wall thickness of 10mm.

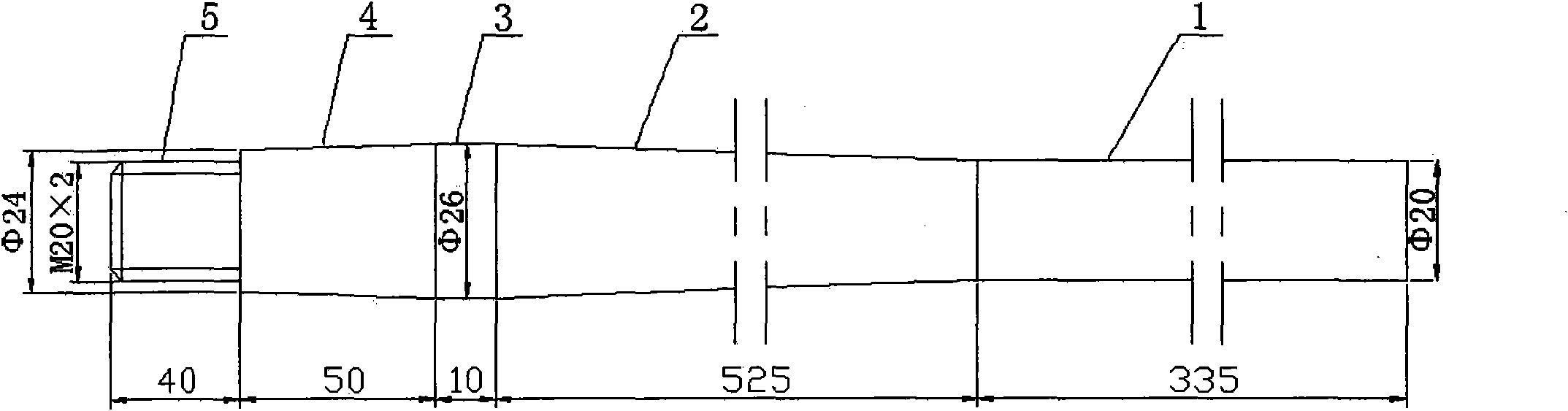

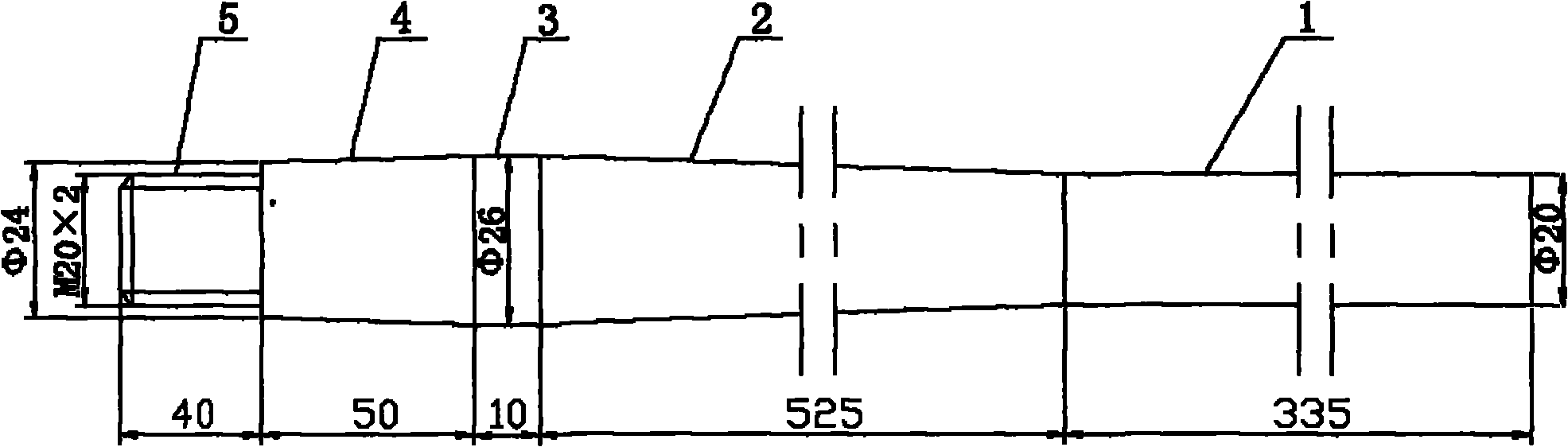

[0015] Such as figure 1 As shown, the rod core used in this cold rolling mill is composed of multi-section continuous cylinders and circular trusses. From front to back, they are: a cylinder 1 with a diameter of 20mm and a length of 335mm, a diameter of 20mm at the front end, and a diameter of 26mm at the rear end. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com