Barrel permanent magnet coupling capable of adjusting coupling space and area of air gap magnetic field

A technology of permanent magnet coupling and air gap magnetic field, applied in the direction of permanent magnet clutch/brake, electric brake/clutch, electrical components, etc., it can solve the problem that the power cannot be made too large, the permanent magnet coupling and the governor cannot be adjusted automatically Air gap spacing, low efficiency of permanent magnet coupling drive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

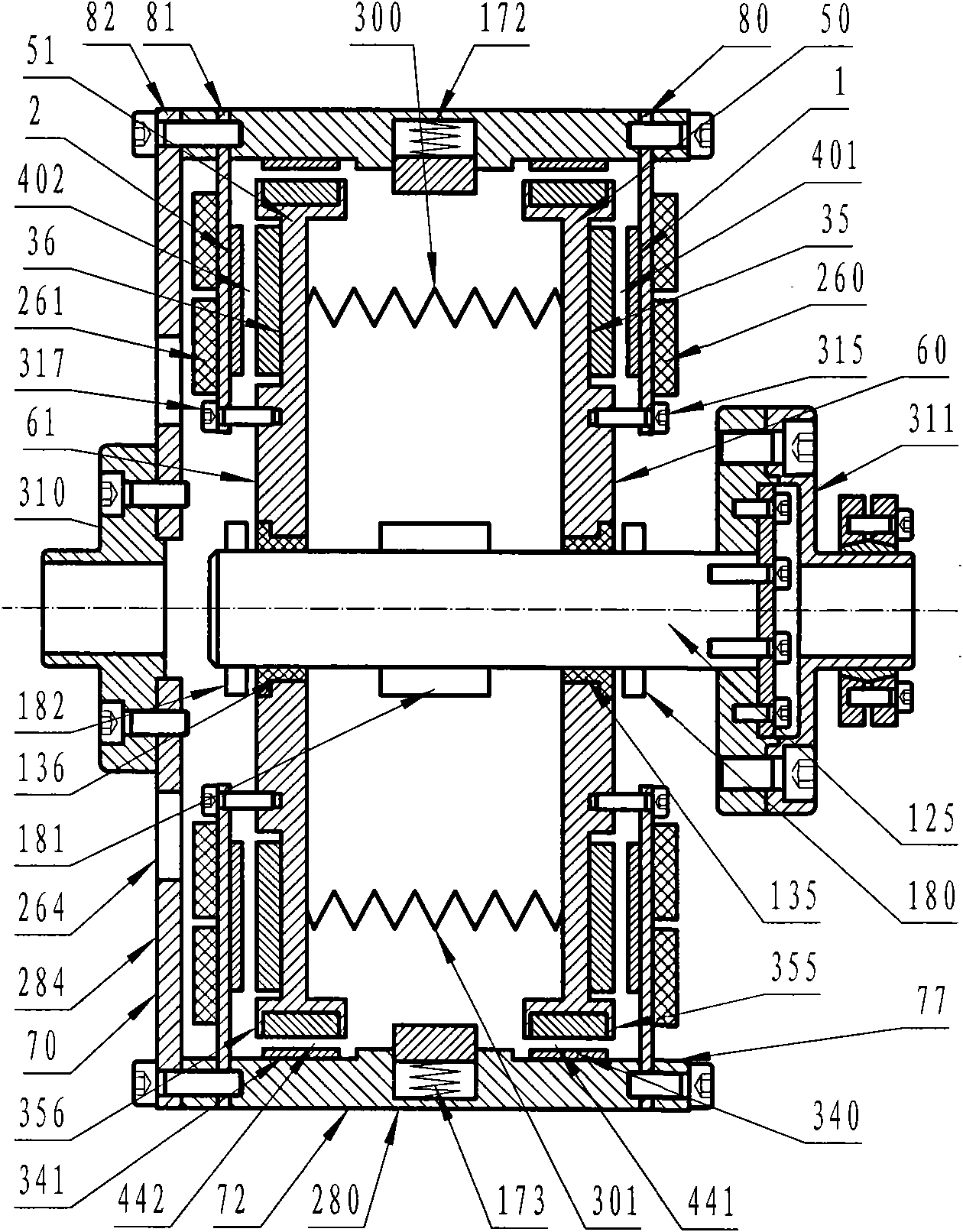

[0050] Such as figure 1 , figure 2 and image 3 As shown, it is a permanent magnetic coupling shaft coupling of a drum type structure composed of two inner drums (50, 51) and an outer drum (70). The end walls (80, 81) of the outer drum are respectively provided with axial magnetic field metal conductor disks (1, 2), and the end walls (60, 61) of the inner drum are respectively provided with axial magnetic field permanent magnet disks (35 , 36), they are respectively correspondingly coupled to form two axial magnetic field metal conductor permanent magnetic coupling assemblies (401, 402), and the inner peripheral surface (77) of the outer drum wall (72) is provided with a radial magnetic field metal conductor disk (320 , 321), the outer circumferential surface (54, 55) of the inner drum wall (52, 53) is provided with a corresponding radial magnetic field permanent magnet disk (355, 356), and is respectively correspondingly coupled to form two radial magnetic field metal cond...

Embodiment 2

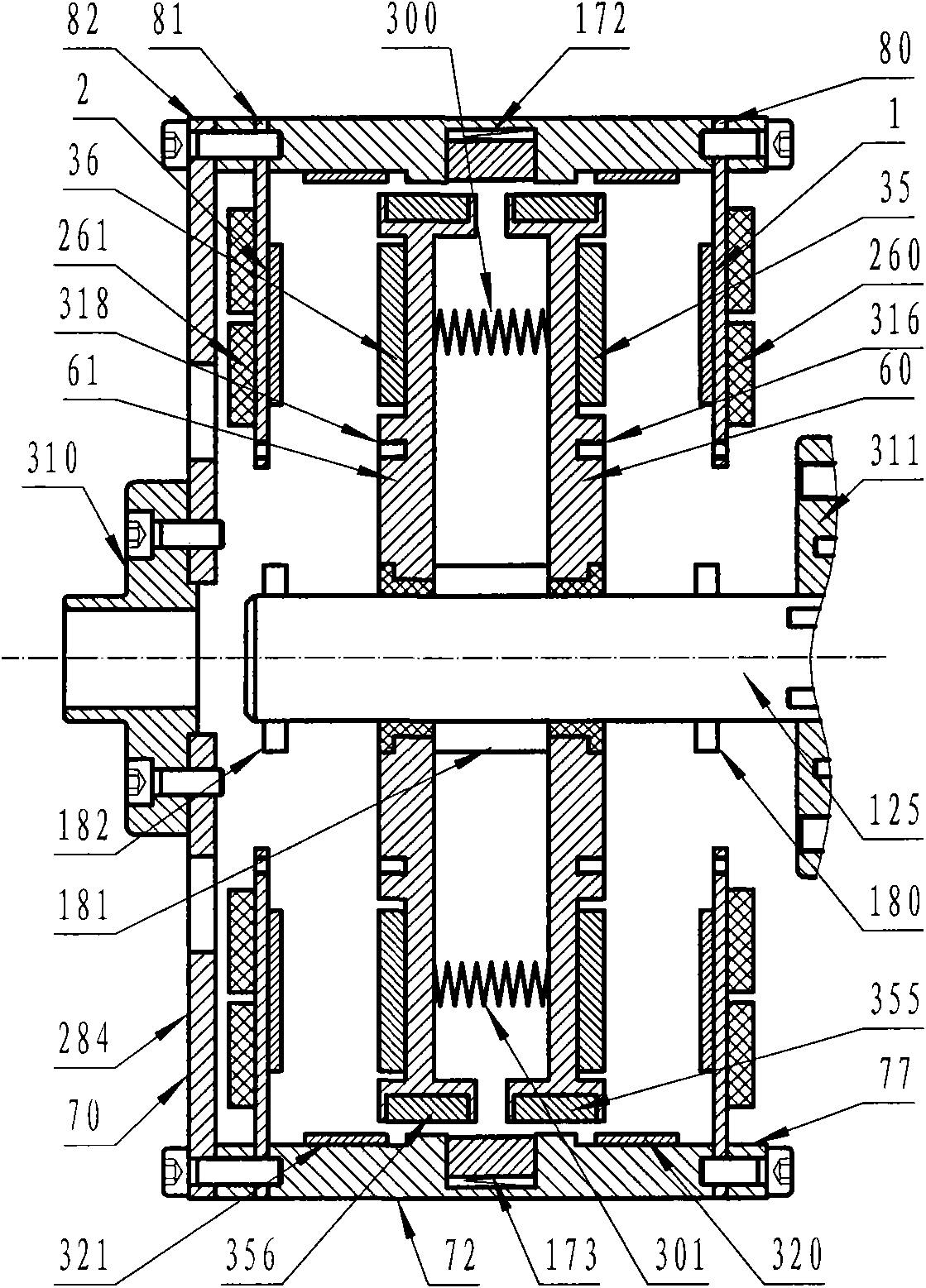

[0054] Such as Figure 4 and Figure 5As shown, it is a permanent magnetic coupling shaft coupling of a drum type structure composed of two inner drums (550, 551) and an outer drum (570). The end walls (580, 581) of the outer drum are respectively provided with axial magnetic field metal conductor disks (510, 511), and the end walls (560, 561) of the inner drum are respectively provided with axial magnetic field permanent magnet disks (535 , 536), they are correspondingly coupled to form two axial magnetic field metal conductor permanent magnetic coupling components, the inner peripheral surface (577) of the outer drum wall (572) is provided with radial magnetic field metal conductor disks (850, 851), inner The outer peripheral surfaces (554, 555) of the drum walls (552, 553) are radial magnetic field permanent magnet disks (855, 856), and are respectively coupled to form a radial magnetic field metal conductor permanent magnetic coupling assembly; air gap spacing and couplin...

Embodiment 3

[0057] Such as Figure 6 and Figure 7 As shown, it consists of axial magnetic field metal conductor disks (1001, 1002) and axial magnetic field permanent magnet disks (1035, 1036) respectively coupled to form axial magnetic field metal conductor permanent magnetic coupling assemblies (1001 and 1035, 1002 and 1036) A permanent magnetic coupling coupling with a turntable structure arranged back to back. In addition, there are radial magnetic field metal conductor disks (1350, 1351) on the inner peripheral surface of the outer drum wall (1072), and the inner drum wall (1052 , 1051) are provided with radial magnetic field permanent magnet discs (1355, 1356) on the outer circumferential surface, and are respectively correspondingly coupled to form a radial magnetic field metal conductor permanent magnetic coupling assembly; the active permanent magnetic coupling turntable coupling mechanism consists of a cage wall (1280 ) and the machine cage end wall (1284), the machine cage end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com