System and method for controlling oxynitride removal

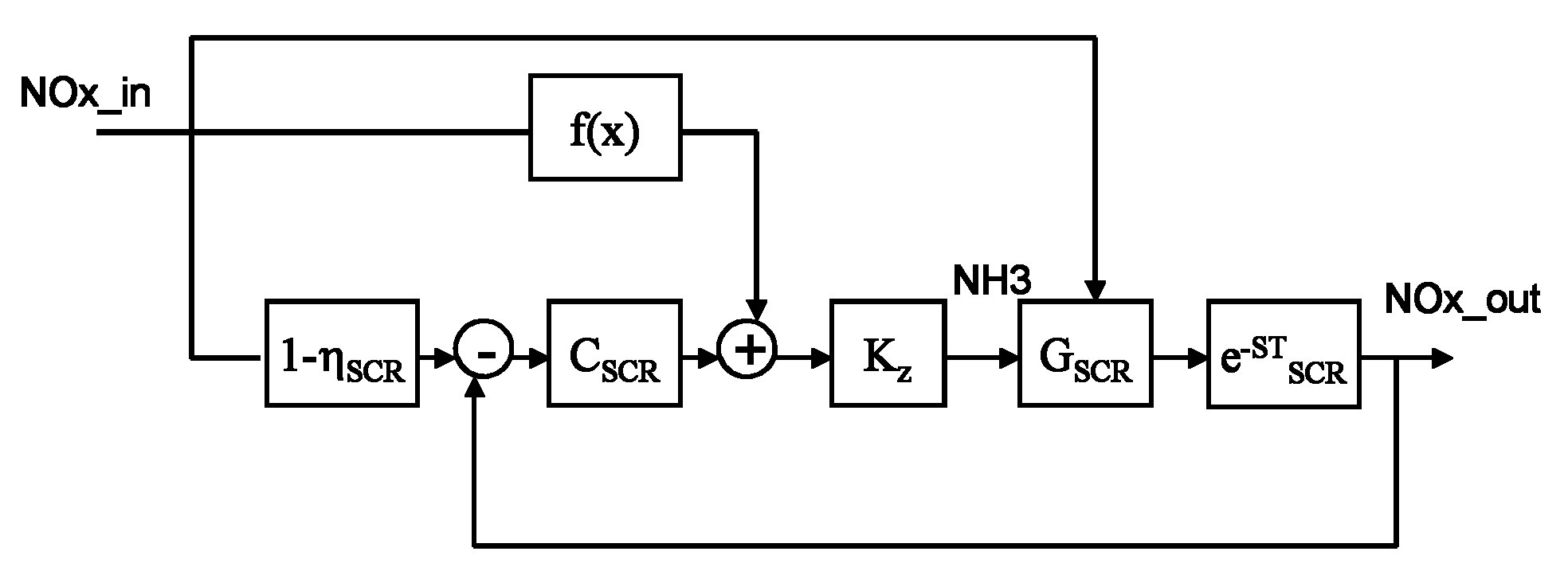

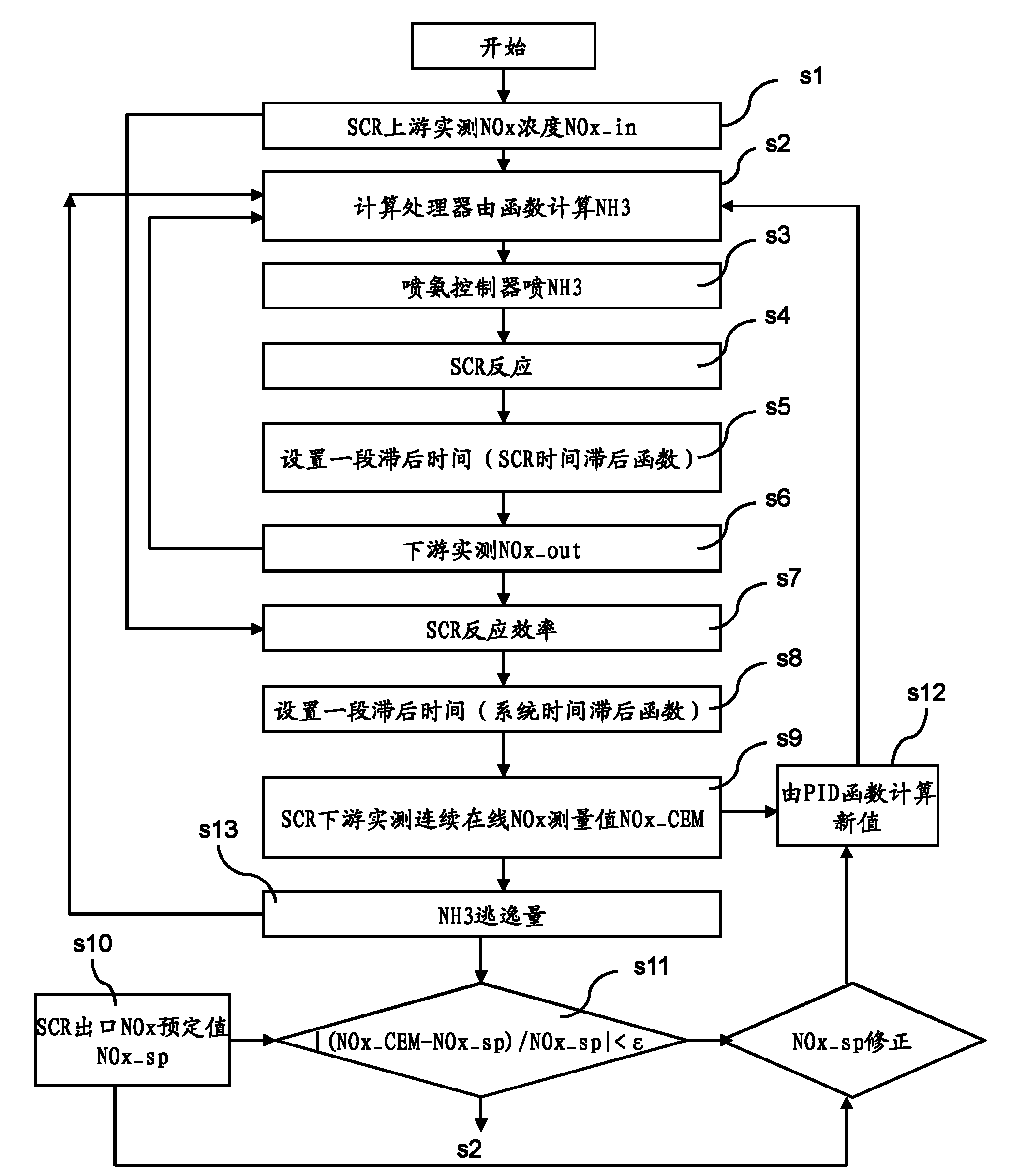

A nitrogen oxide and control system technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve problems such as the inability to guarantee the amount of ammonia escape, the influence of control effectiveness, the inability to guarantee the NOx value NOx_out, etc., to avoid Ammonia escaping, overcoming the effects of time lag, eliminating the effect of fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] Reference herein to "one embodiment" or "an embodiment" refers to a particular feature, structure or characteristic that can be included in at least one implementation of the present invention. "In one embodiment" appearing in different places in this specification does not all refer to the same embodiment, nor is it a separate or selective embodiment that is mutually exclusive with other embodiments. Furthermore, the order of elements in a method, flowchart, or functional block diagram representing one or more embodiments does not necessarily refer to any particular order nor constitute a limitation of the present invention.

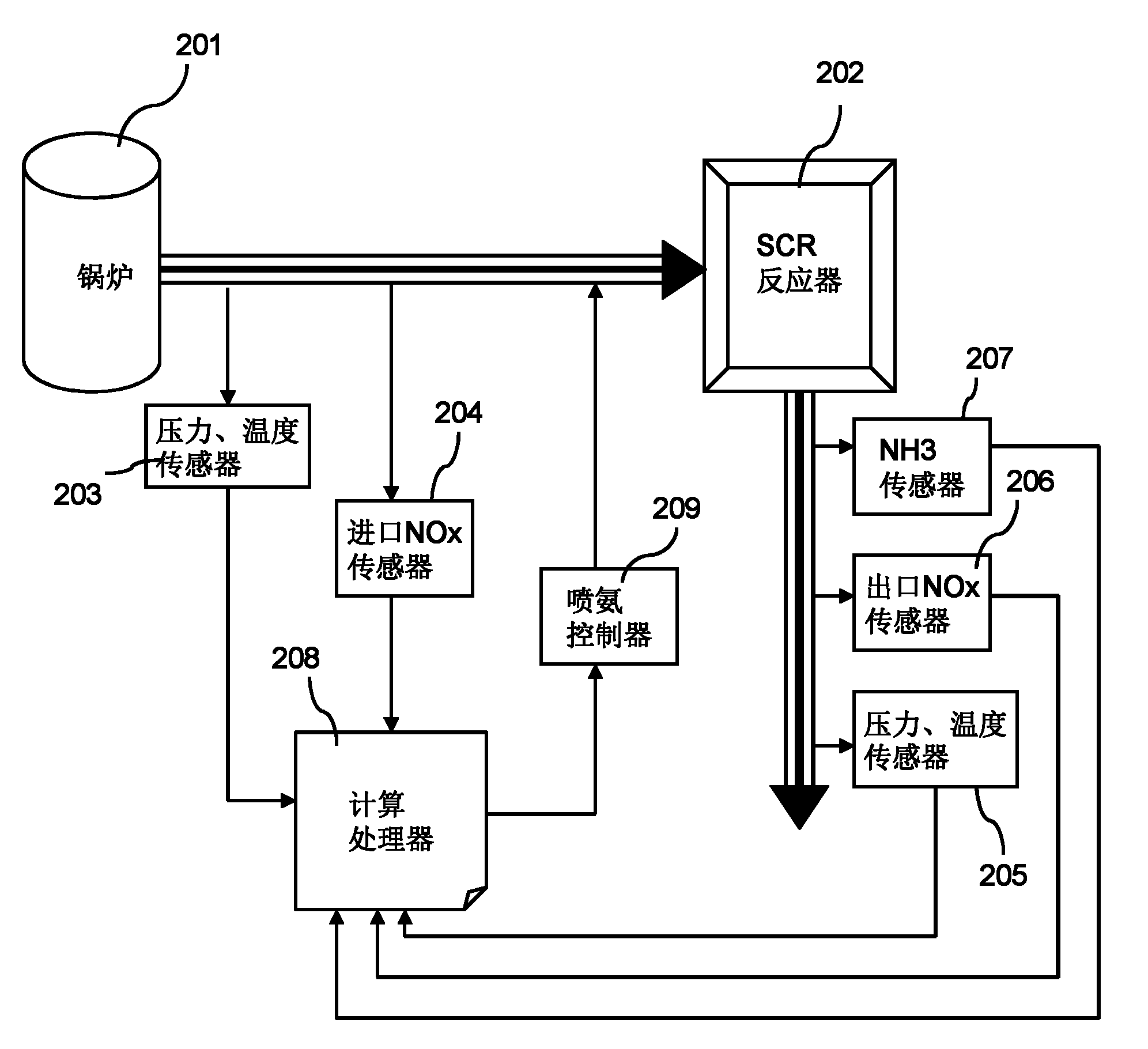

[0058] In one embodiment of the present invention, the denitrification control system of the present invention is applied in a coal-fired power plant, and the flue gas containing nitrogen oxides discharged from the combustion boiler of the coal-fired power plant is discharged after being treated by the denitrification control system of the present...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com