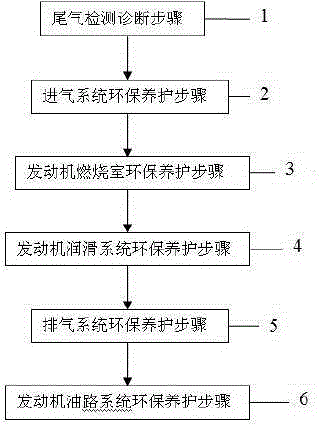

Engine and long-acting environment-friendly maintenance method for air intake and exhaust system

A technology of air intake system and exhaust system, which is applied in the direction of engine components, machines/engines, mechanical equipment, etc. It can solve the problems of oxygen sensor and three-way catalytic converter, marginal lubrication, and engine Combustion chamber wear and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075] Embodiment 1: When the present invention is applied to the long-term environmental maintenance of motor vehicle gasoline engines, the following sub-steps are carried out successively:

[0076] S1 uses waste detection analyzers and vehicle decoders to analyze vehicle exhaust;

[0077] S2 removes dust from the air filter of the intake system;

[0078] S3 adds a special engine cleaning agent with high adhesion to metal materials to the engine;

[0079] S4 keeps the engine speed at 2200-2500r / min for 20 minutes to clean some carbon deposits and sludge inside the engine;

[0080] The S5 engine runs at full speed for 5 hours, so that the special cleaning agent can clean the oil sludge and carbon deposits inside the engine;

[0081] S6 flameout, wait for the engine to cool down, replace the lubricating oil and oil filter with nano-scale composite alloy lubricating factor;

[0082] S7 After the engine runs normally for 50 hours, open the oil pan to remove the sediment;

[0...

Embodiment 2

[0088] Embodiment 2: When the present invention is applied to the long-term environmental maintenance of motor vehicle diesel engines, the following sub-steps are carried out in sequence:

[0089] S1 uses waste detection analyzers and vehicle decoders to analyze vehicle exhaust;

[0090] S2 removes dust from the air filter of the intake system;

[0091] S3 adds a special engine cleaning agent with high adhesion to metal materials to the engine;

[0092] S4 keeps the engine speed at 2200-2500r / min for 20 minutes to clean some carbon deposits and sludge inside the engine;

[0093] The S5 engine runs at full speed for 5 hours, so that the special cleaning agent can clean the oil sludge and carbon deposits inside the engine;

[0094] S6 flameout, wait for the engine to cool down, replace the lubricating oil and oil filter with nano-scale composite alloy lubricating factor;

[0095] S7 After the engine runs normally for 50 hours, open the oil pan to remove the sediment;

[0096...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com