A long-term environmental protection maintenance method for engine and intake and exhaust system

An air intake system and exhaust system technology, which is applied in the directions of engine components, machines/engines, exhaust devices, etc., can solve the problem that the oxygen sensor and three-way catalytic converter cannot be used for a long time, and the wear of the engine combustion chamber cannot be solved. Solve problems such as marginal lubrication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

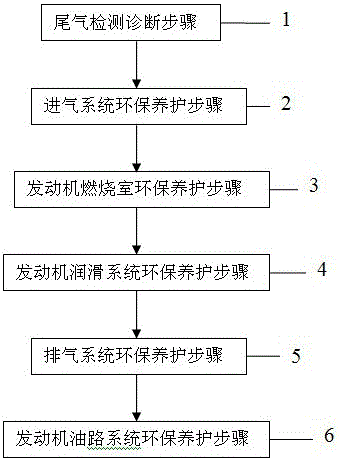

Method used

Image

Examples

Embodiment 1

[0077] Embodiment 1: When the present invention is applied to the long-term environmental maintenance of motor vehicle gasoline engines, the following sub-steps are carried out successively:

[0078] S1 Carry out exhaust gas analysis of vehicles with waste detection analyzers and vehicle decoders;

[0079] S2 to remove dust from the air filter of the intake system;

[0080] S3 Add a special engine cleaning agent with high adhesion to metal materials to the engine;

[0081] S4 Keep the engine speed at 2200-2500 r / min for 20 minutes to clean some carbon deposits and sludge inside the engine;

[0082] The S5 engine runs at full speed for 5 hours, so that the special cleaning agent can clean the oil sludge and carbon deposits inside the engine;

[0083] S6 Turn off the engine, wait for the engine to cool down, replace the lubricating oil and oil filter with nano-scale composite alloy lubricating factor;

[0084] S7 After the engine runs normally for 50 hours, open the oil pan t...

Embodiment 2

[0090] Embodiment 2: When the present invention is applied to the long-term environmental maintenance of motor vehicle diesel engines, the following sub-steps are carried out in sequence:

[0091] S1 Carry out exhaust gas analysis of vehicles with waste detection analyzers and vehicle decoders;

[0092] S2 to remove dust from the air filter of the intake system;

[0093] S3 Add a special engine cleaning agent with high adhesion to metal materials to the engine;

[0094] S4 Keep the engine speed at 2200-2500 r / min for 20 minutes to clean some carbon deposits and sludge inside the engine;

[0095] The S5 engine runs at full speed for 5 hours, so that the special cleaning agent can clean the oil sludge and carbon deposits inside the engine;

[0096] S6 Turn off the engine, wait for the engine to cool down, replace the lubricating oil and oil filter with nano-scale composite alloy lubricating factor;

[0097] S7 After the engine runs normally for 50 hours, open the oil pan to r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com