Reciprocating rotation type feed liquid and film separation method and device

A reciprocating rotation and membrane separation technology, which is applied in the field of membrane separation, can solve the problems of high energy consumption and poor separation effect of material-liquid filtration, and achieve the effects of increasing liquid shear stress, inhibiting membrane fouling and concentration polarization, and delaying attenuation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

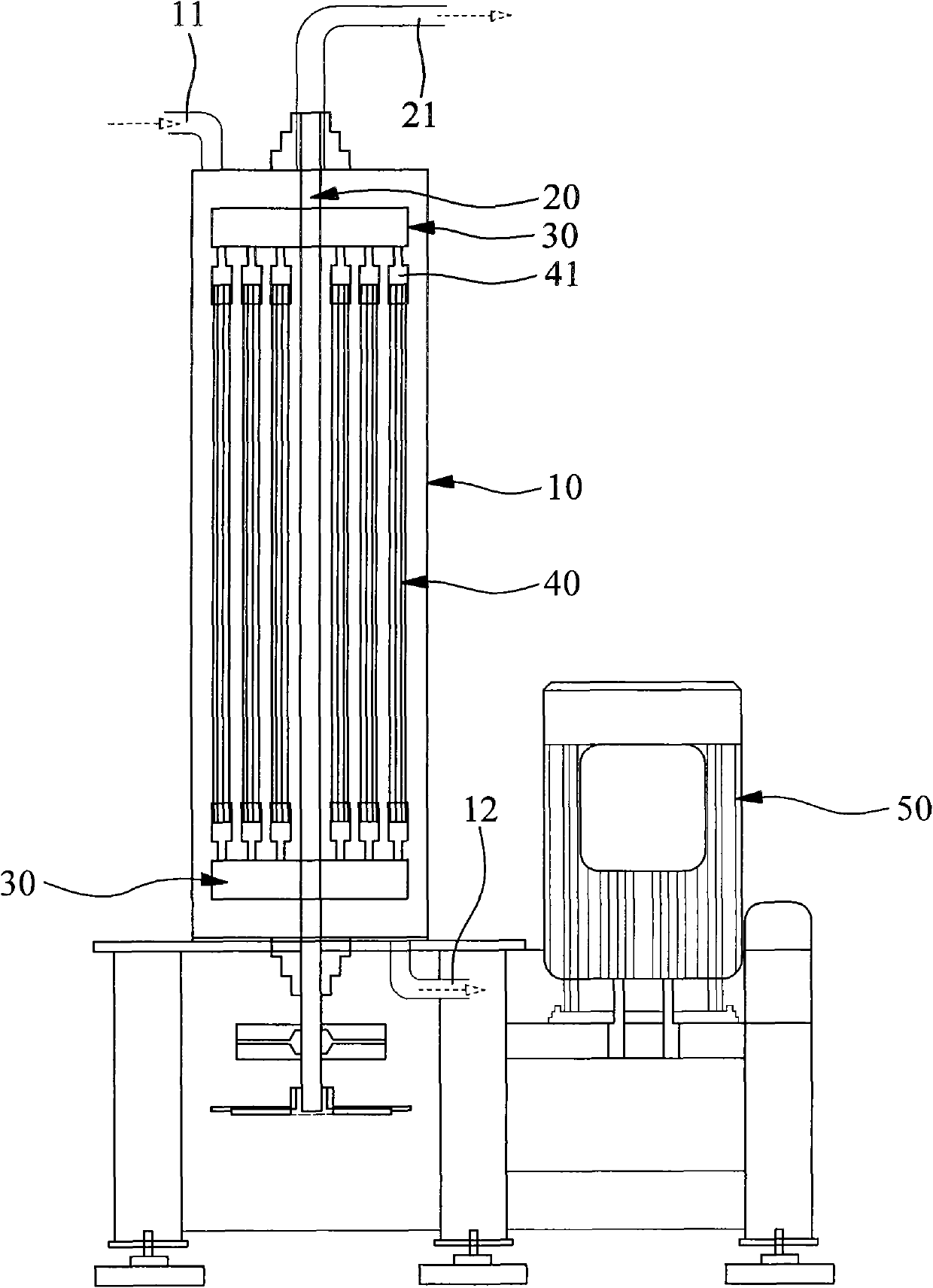

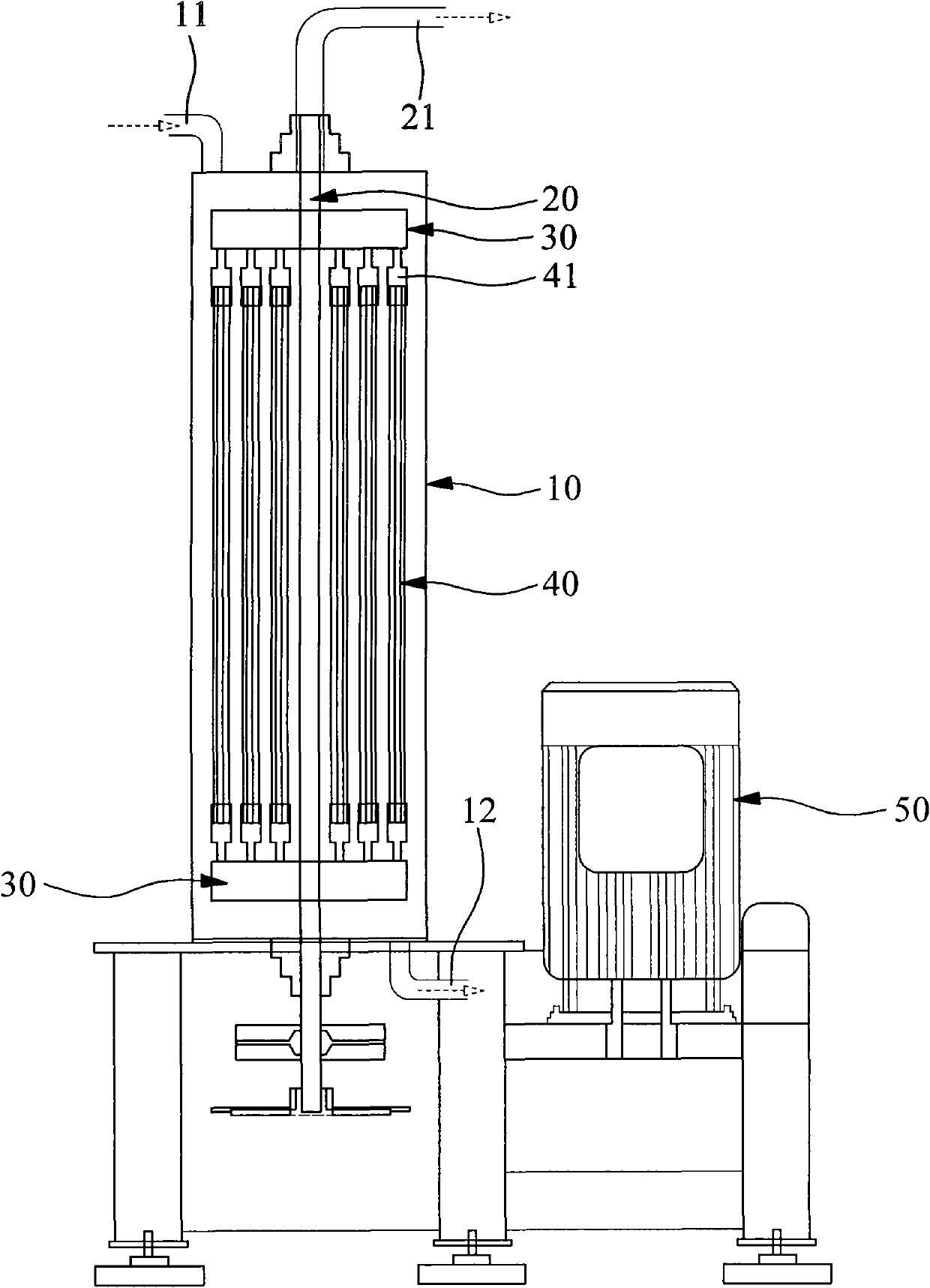

[0030] Please refer to figure 1 As shown, it shows the specific structure of the first preferred embodiment of the present invention, including a material liquid cylinder 10, a hollow shaft 20, two rotating disks 30, a plurality of membrane modules 40 and a driving mechanism 50.

[0031] Wherein, the material-liquid cylinder 10 is provided with a material-liquid inlet 11 and a material outlet 12 that communicate with the outside world and the inside of the material-liquid cylinder 10, the material-liquid inlet 11 is located at the upper end of the material-liquid cylinder 10, and the material-liquid inlet 11 is set There is a feed pump (not shown in the figure), and the feed pump is used to fill the feed liquid cylinder 10. Of course, it can also be manually filled, which is not limited. The discharge port 12 is located at the lower end of the material liquid cylinder 10, and the discharge port 12 is used for discharging the concentrated liquid.

[0032] The hollow rotating s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com