Waste and old tyre powder modified asphalt grinding machine

A technology of waste tire powder and modified asphalt, which is applied in the field of building materials-asphalt processing equipment, can solve the problems of unstable product ductility index, harsh production conditions, and high production costs, and achieve remarkable benefits and effects. The effect of stabilizing quality and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] specific implementation

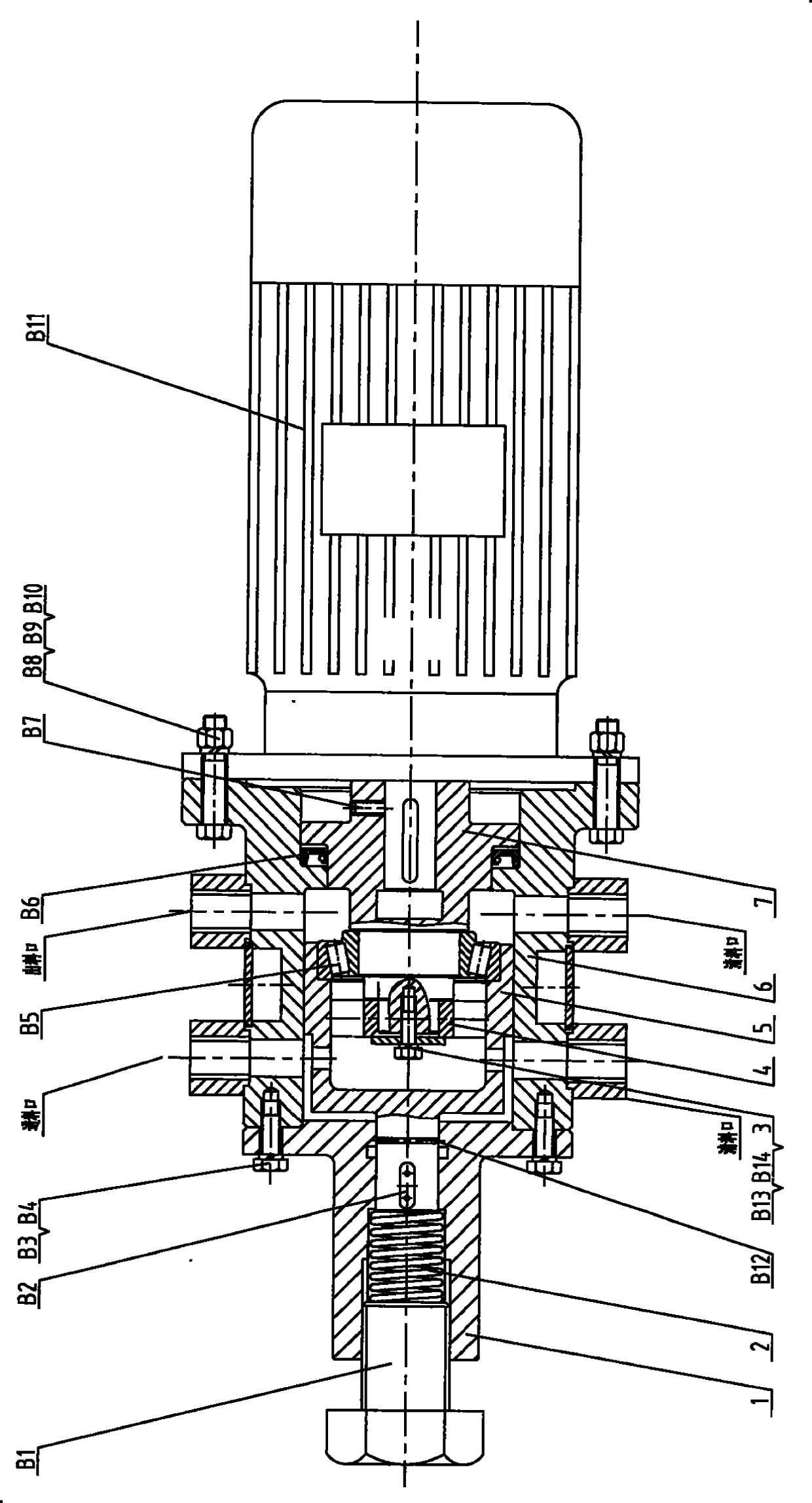

[0031] Explanation of marks in the drawings: 1—sleeve one; 2—spring; 3—retaining ring; 4—phoenix fan; 5—thrust rod; 6 sleeve two; 7—rotation shaft; B1—bolt; B2—round head Guide flat key; B3—bolt; B4—washer; B5—bearing; B6—O-ring; B7—set bolt; B8—bolt; B9—nut; B10—washer; B11—high temperature motor; B12—lip type Seal; B13—bolt; B14—washer.

[0032] The waste tire powder modified asphalt grinder of the embodiment of the present invention comprises a high-temperature motor, a cone roller bearing or a cylindrical roller bearing or a needle roller bearing or a centripetal thrust bearing, and a pump casing (sleeve one, Sleeve 2), spring, retaining ring, fan, thrust rod, rotating shaft, garden head guide flat key, silicone sealing ring, the inner ring of the bearing is connected to the rotating shaft of the high-temperature motor, the outer ring of the bearing is installed on the thrust rod, and the pump There is a material inlet and a material outl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com