Technology for preparing iron ore concentrate

A preparation process and iron concentrate technology, which is applied in the field of iron concentrate preparation process, can solve the problems of poor economic benefits and low price of iron concentrate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

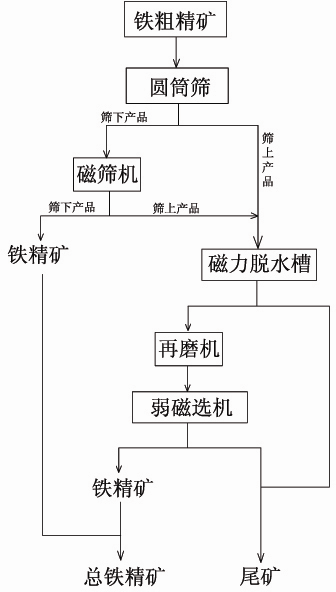

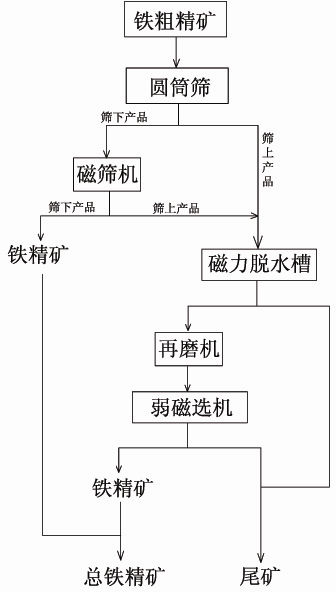

Image

Examples

Embodiment 1

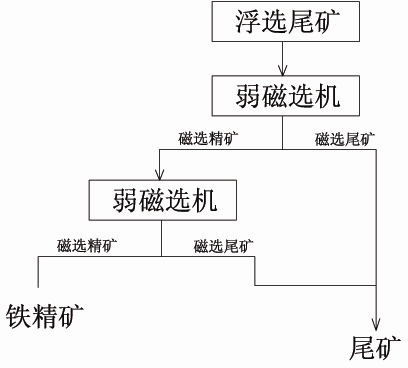

[0015] The Huangshaping iron-polymetallic ore dressing plant in Chenzhou, Hunan Province mainly deals with iron ore and polymetallic ore. In actual production, the two kinds of ores have not been strictly separated and sorted. Production process see figure 2 , the grade of raw ore is about 11%, the grade of iron concentrate is about 60-61%; the theoretical recovery rate of iron concentrate is about 65%. After using this process, the final grade of iron concentrate is increased from 60% to 63%. The recovery rate is increased to 68%, and the economic benefit is good.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com