Cone drum for piston pusher centrifuge

A centrifuge and drum technology, applied in the direction of centrifuges, etc., can solve the problems of increasing the production cost of centrifuges, increasing maintenance costs, cost performance and hindering the development of multi-stage pusher centrifuges, etc., to achieve a wide range of use and low manufacturing and maintenance costs. Low, good dehydration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

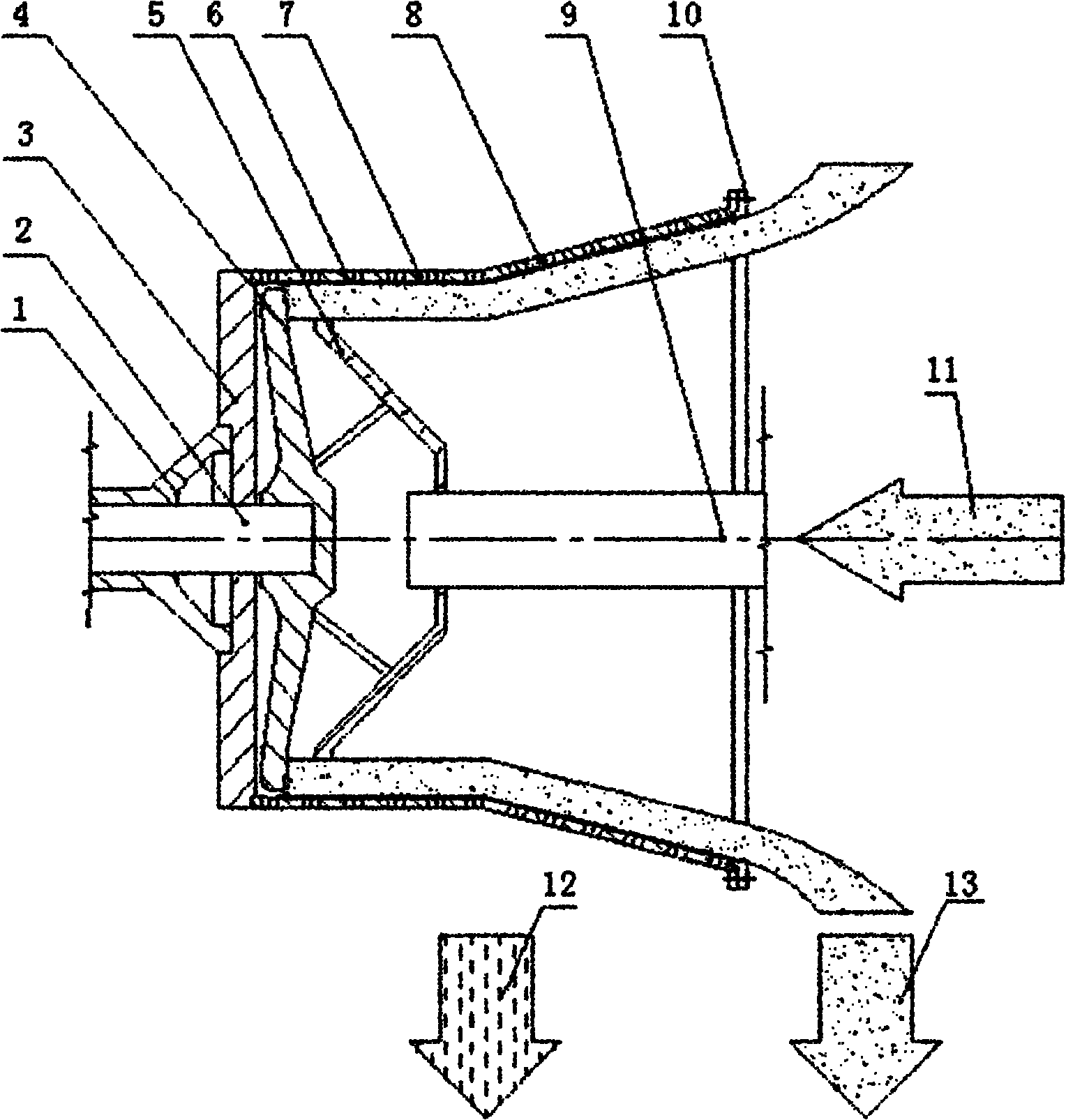

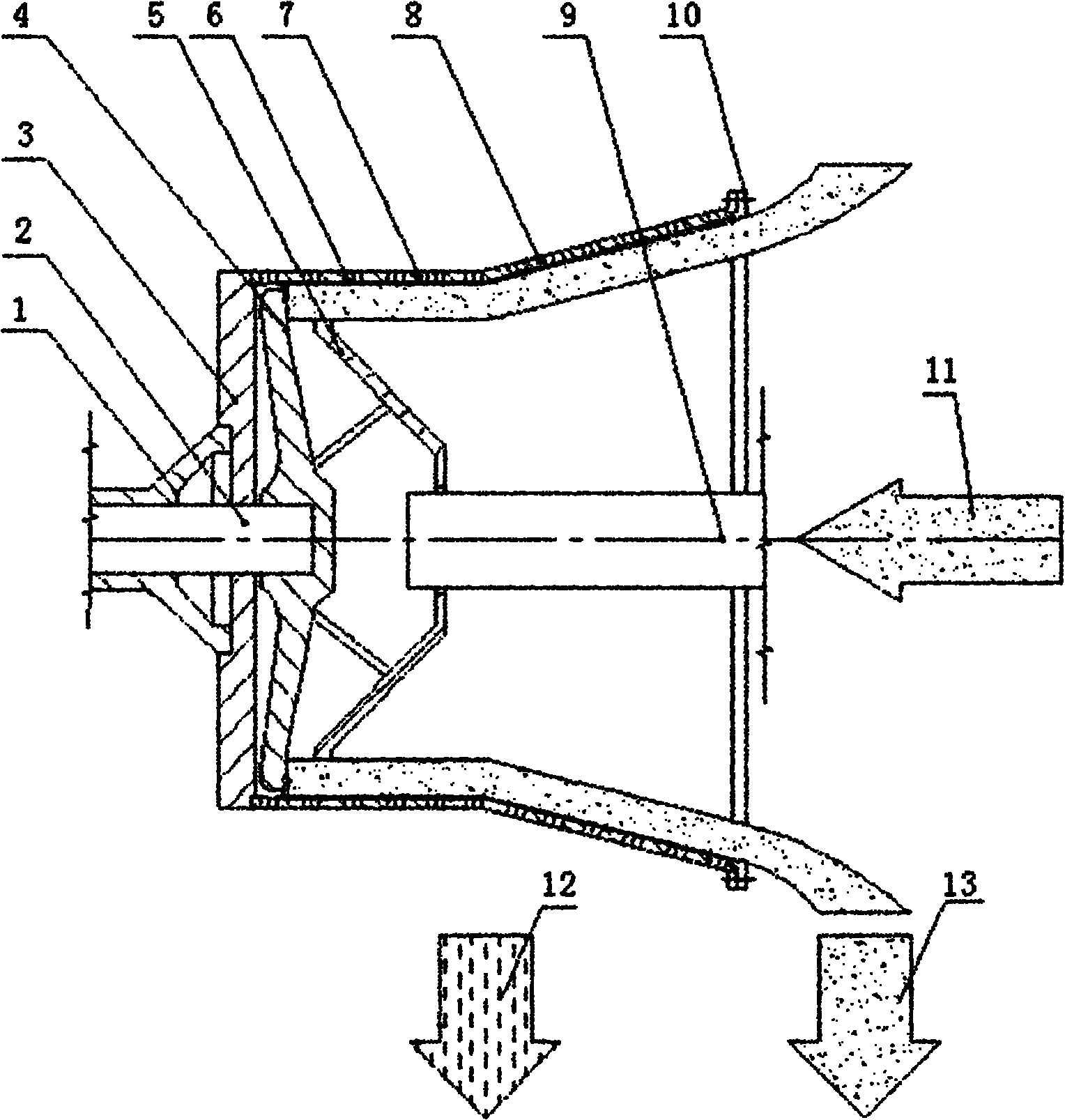

[0019] Such as figure 1 As shown, the cylindrical-cone drum used for the piston pusher centrifuge includes a wheel 3 connected to the main shaft 1, and the drum body is connected to the wheel with screws to form a drum. The drum body is composed of a cylindrical body 7 and a conical body. The 8 small ends are connected by a smooth transition. The push plate 4 is fixed on one end of the push rod 2. The push plate 4 and the push rod 2 run through the main shaft 1 and the drum body. The distributor 5 is connected to the push plate by several ribs. 4, the feed pipe 9 is fixed on the solid-liquid tank of the centrifuge, and passes into the hole of the distributor 5; when the column-cone-piston pusher centrifuge separates heavy alkali (NaHCO3), the water content of the suspension feed is 18 %, the average particle size of the solid phase is 80 to 90 microns, the semi-cone angle of the conical cylinder 8 can be 10°, and its large end is the discharge end; The porosity is 35%, and th...

Embodiment 2

[0021] Such as figure 1 As shown, the cylindrical-cone drum used for the piston pusher centrifuge includes a wheel 3 connected to the main shaft 1, and the drum body is connected to the wheel with screws to form a drum. The drum body is composed of a cylindrical body 7 and a conical body. The 8 small ends are connected by a smooth transition. The push plate 4 is fixed on one end of the push rod 2. The push plate 4 and the push rod 2 run through the main shaft 1 and the drum body. The distributor 5 is connected to the push plate by several ribs. 4, the feed pipe 9 is fixed on the solid-liquid tank of the centrifuge, and passes into the hole of the distributor 5; when the column-cone-piston pusher centrifuge separates the salt, the water content of the suspension feed is 70% to 80%. , the solid phase average particle size is 110 microns, the half-cone angle of the conical cylinder 8 is 8°, and its big end is the discharge end; %, and the inner circumferential surface of the cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com