Power vibration absorber

A technology of dynamic vibration absorber and vibration damping rod, which is applied in the direction of metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc. It can solve the problems of unsatisfactory vibration reduction effect, non-adjustable, narrow control frequency band, etc., and achieve vibration absorption effect Good, realize the effect of automatic control and vibration reduction frequency bandwidth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

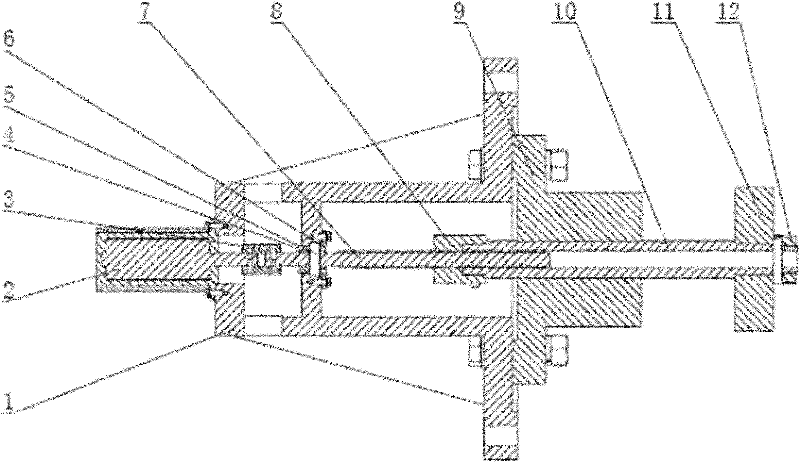

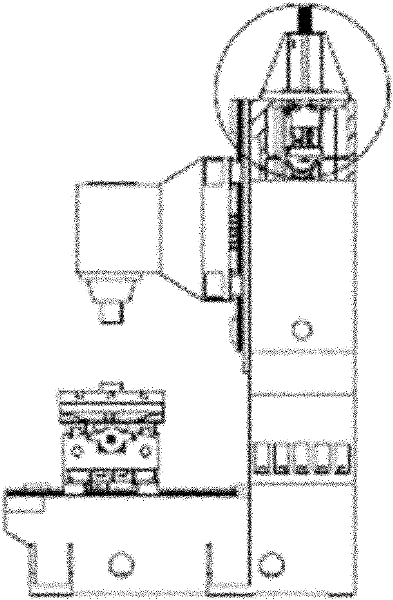

[0021] The dynamic vibration absorber of the present invention is described in detail below in conjunction with accompanying drawing:

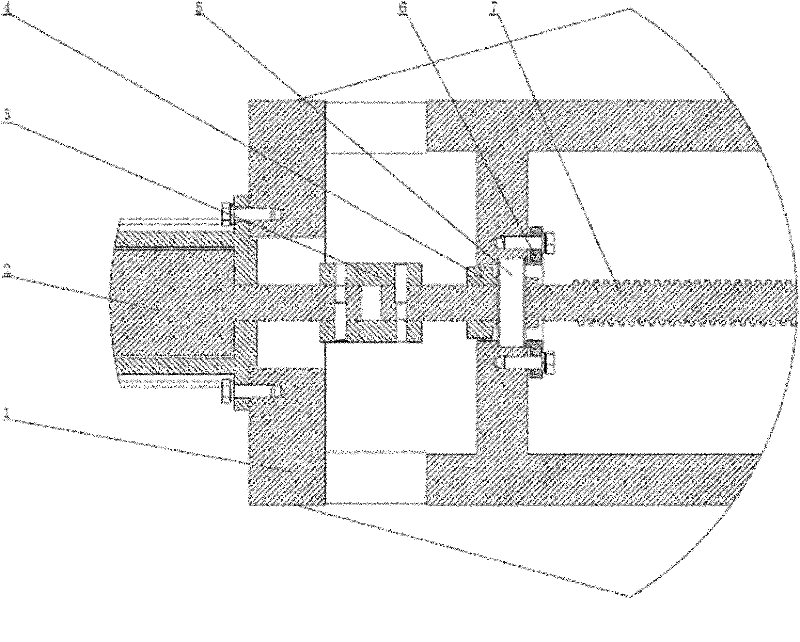

[0022] see figure 1 and combine figure 2 As shown, the dynamic vibration absorber of the present invention includes a bracket 1, a servo motor 2 fixed at one end of the bracket 1, a screw 7 fixedly connected to the servo motor 2 through a coupling 3, a transmission nut 8 connected to the screw 7 through threads, and a transmission The damping rod 10 fixedly connected to the nut 8, the damping seat 9 fixedly connected to the bracket 1 and opposite to the servo motor 2, and the mass block 11 fixed on the other end of the damping rod 10 and opposite to the drive nut 8, the The other end of the mass block 11 is fixed on the damping rod 10 by a nut 12 .

[0023] Please see in particular figure 2 As shown in Figure 5, the servo motor 2 is fixed on the bracket 1 by screws; the bracket 1 is provided with a bearing seat, and the deep groove ball b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com