Processing precision property online measurement device and method for super-heavy lathe

A technology of lathe processing and measuring device, which is applied to metal processing mechanical parts, metal processing equipment, measuring/indicating equipment, etc., can solve the problems of inability to obtain valid data and inapplicable to online measurement of workpieces processed by super-heavy machine tools.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

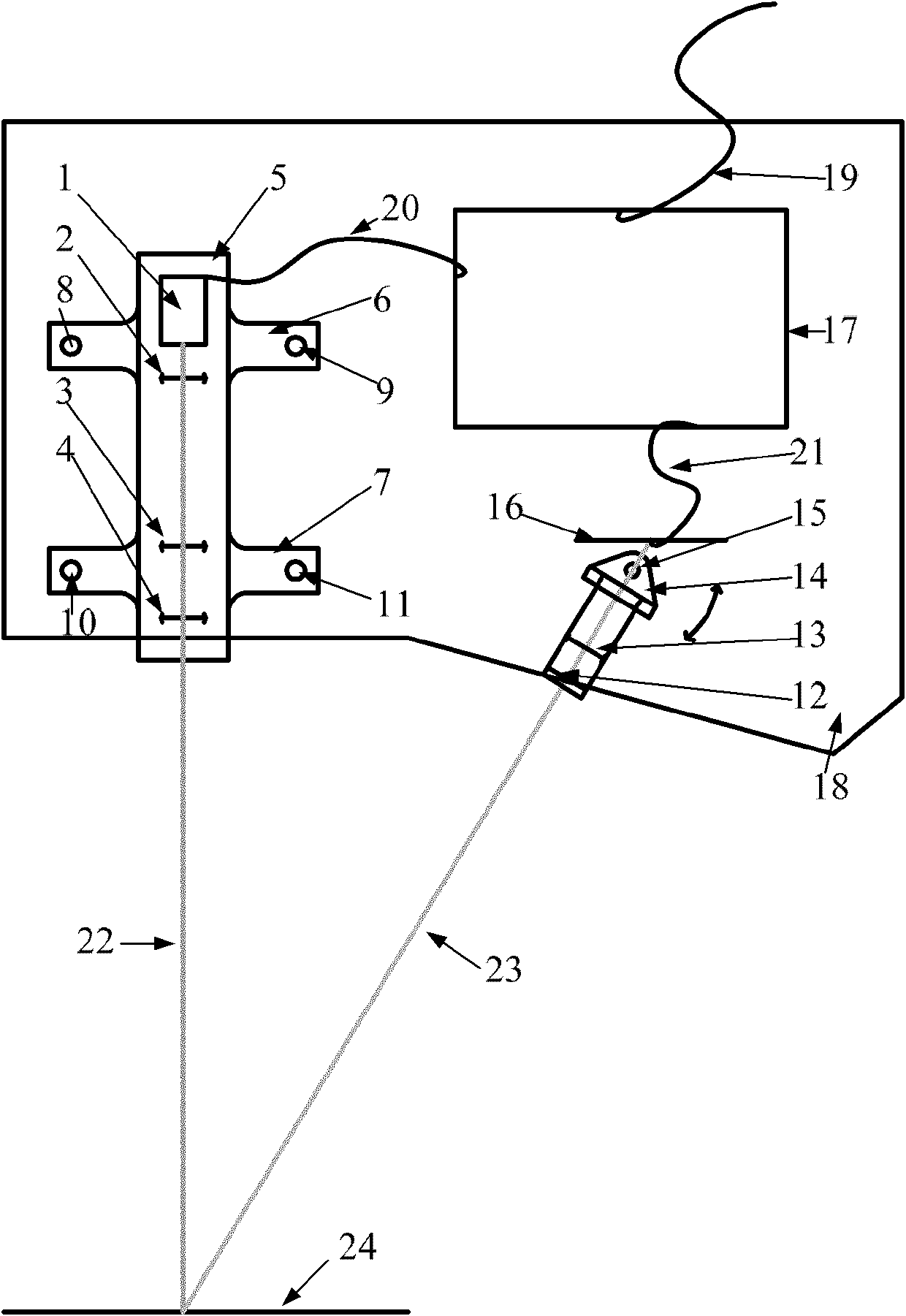

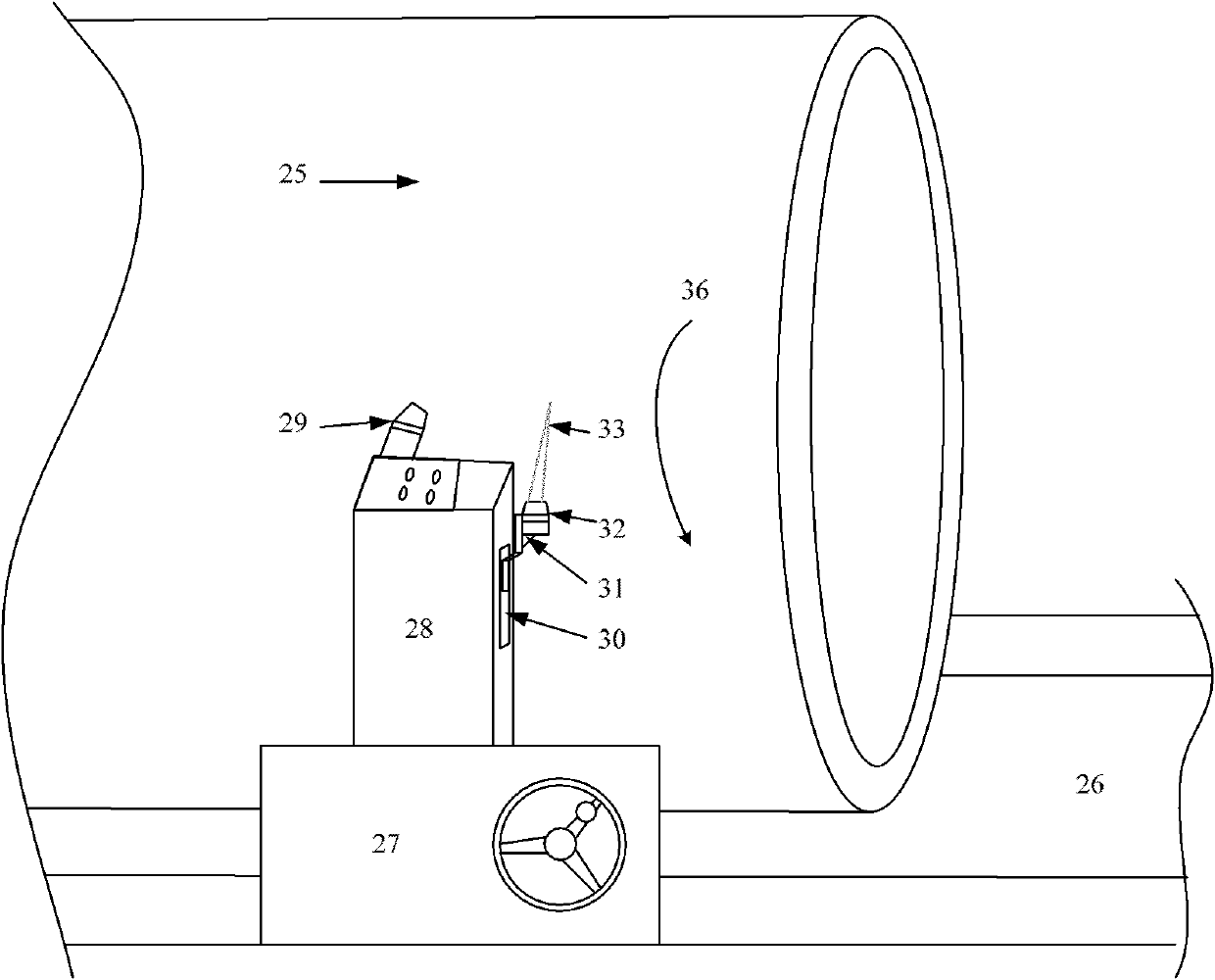

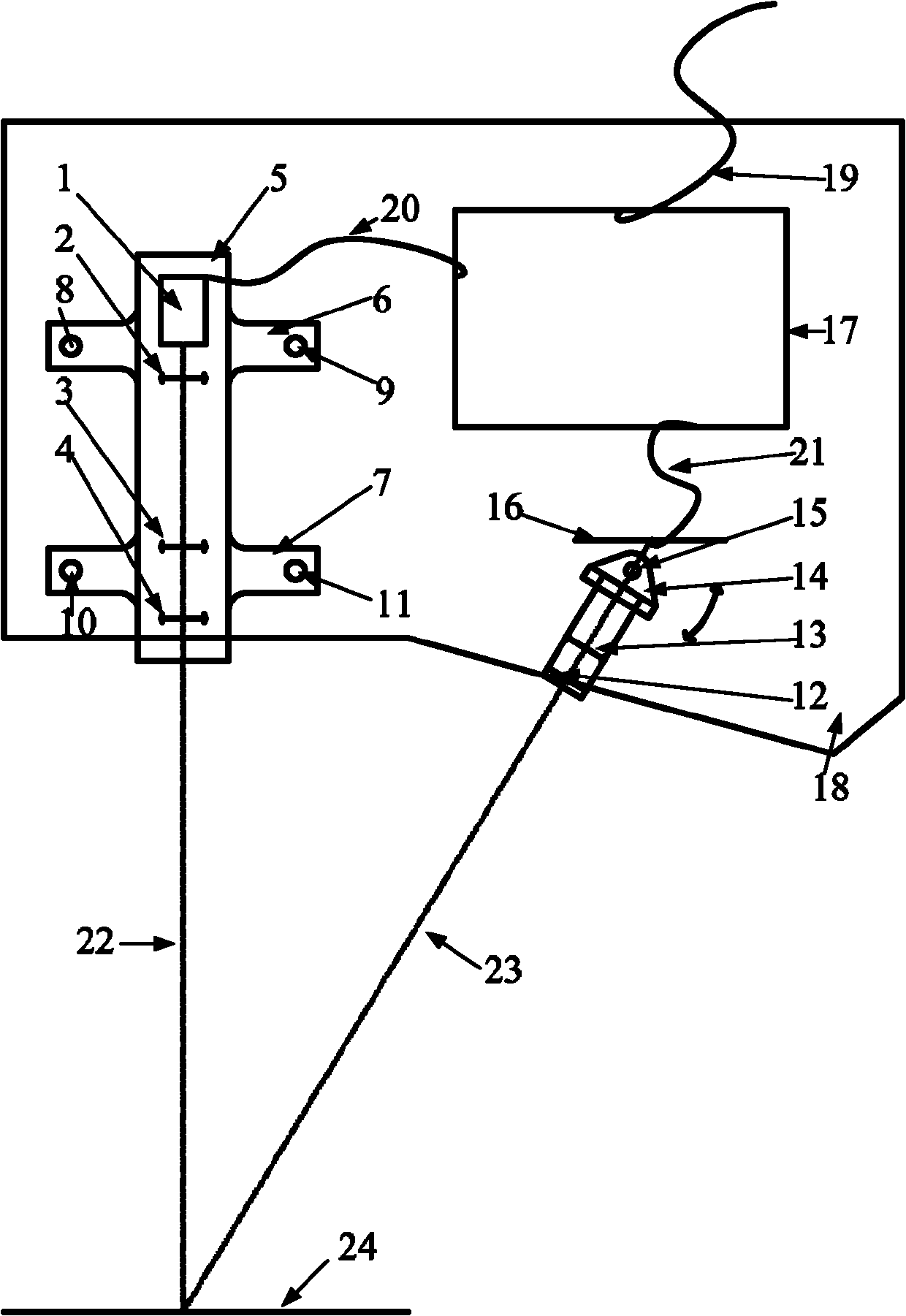

[0021] see figure 1 , the on-machine measuring device of the processing accuracy characteristics of the ultra-heavy-duty lathe based on the optical sensing method involved in the present invention passes the laser beam emitted by the semiconductor laser through the converging lens, and then passes through the collimating lens group to obtain the laser beam in the measurement range, that is, before the converging lens. Within the range of 100-500mm on the surface, each length is within the range of 25mm from the waist of the laser beam, and the diameter of the laser beam is less than 40um. The laser beam is reflected by the surface of the workpiece, and the interference light wave components are removed by the filter, and the image is formed by the imaging lens. The frequency range of the light wave transmitted by the filter is consistent with the light wave frequency range of the semiconductor laser used. The laser spot is received by a high-speed linear image sensor. A set ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com