Filter seat

A filter and filter seat technology, which is applied to fuel air filters, machines/engines, engine components, etc., can solve problems such as waste, hidden dangers, and insufficient engine power, and achieve improved efficiency and reliability. Service life, the effect of avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

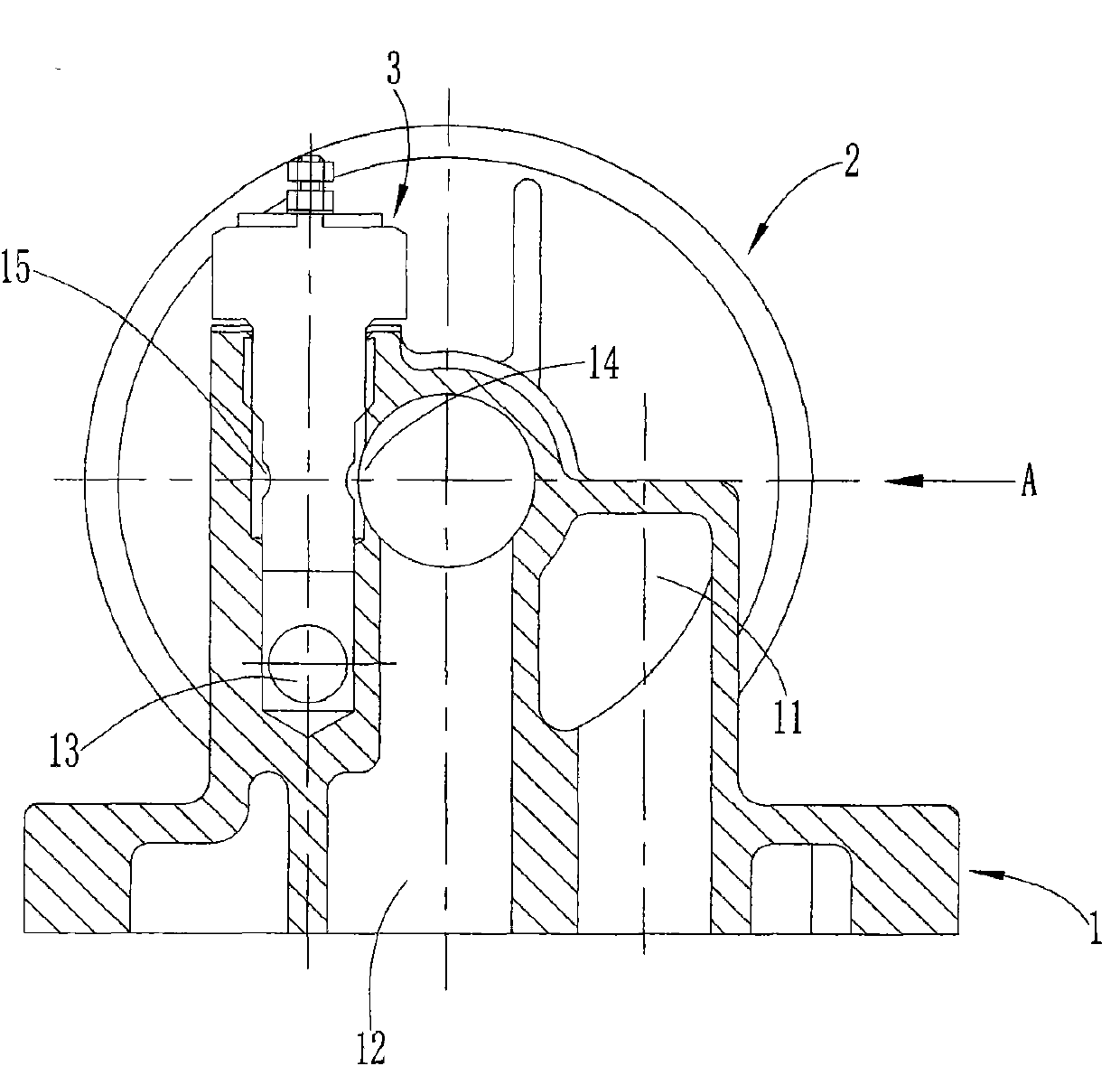

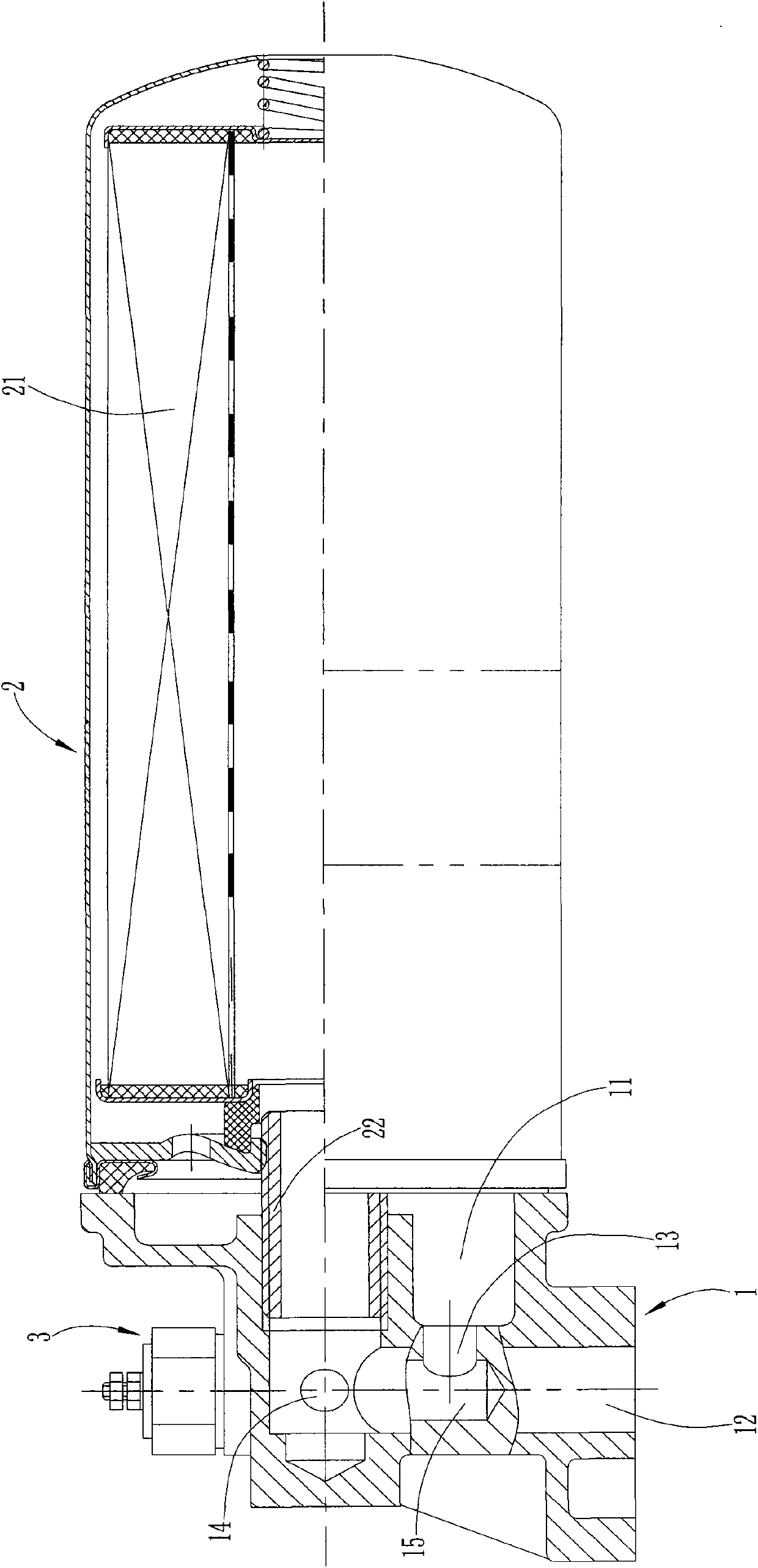

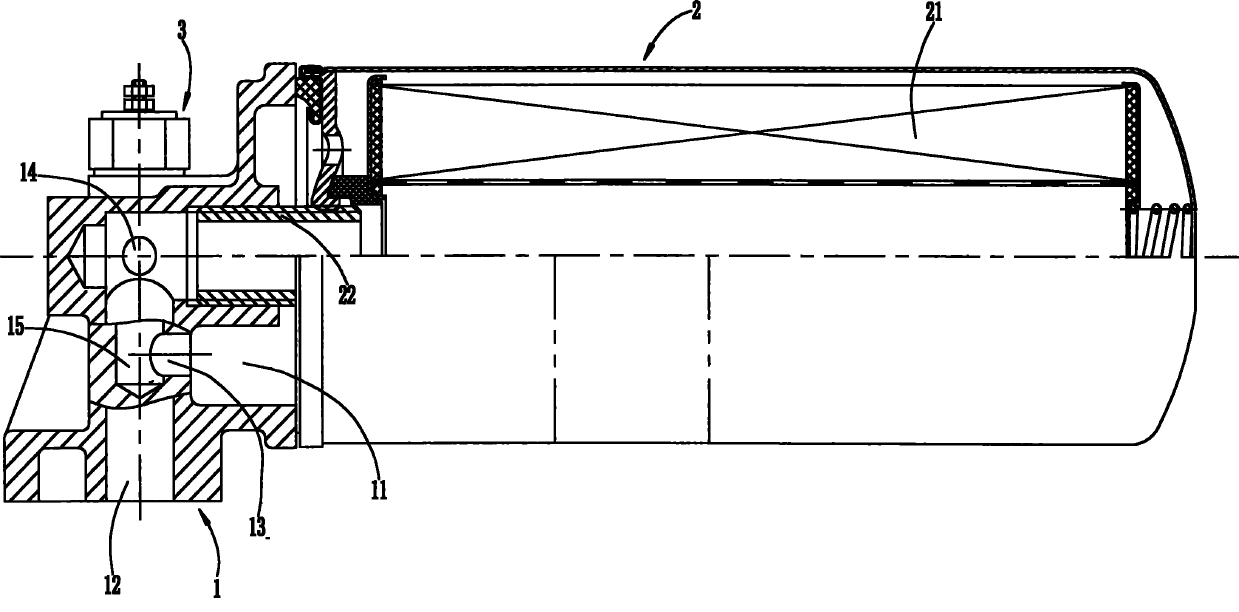

[0019] see figure 1 , figure 2 , The filter tank 2 of the filter is equipped with this filter seat through the center pipe 22 on it, and the filter element 21 is installed in the filter tank 2 . The body 1 of the filter seat is provided with an oil inlet chamber 11 and an oil outlet chamber 12 that are separately communicated with the inner cavity of the filter tank 2, and the body 1 is provided with a differential pressure sensor 3 through a vertically arranged jack 15, and the body 1 is also provided An oil hole 13 and an oil hole 14 are arranged, the oil hole 13 communicates with the lower part of the oil inlet chamber 11 and the jack 15 respectively, and the oil hole 14 communicates with the middle part of the oil outlet chamber 12 and the jack 15 respectively, so that the differential pressure sensor 3 It communicates with the oil inlet chamber 11 and the oil outlet chamber 12 separately, and the differential pressure sensor 3 is connected with the input end of the car ...

Embodiment 2

[0021] The differential pressure sensor is a compression spring type differential pressure sensor, and the others are the same as in Embodiment 1.

Embodiment 3

[0023] The differential pressure sensor is a semiconductor differential pressure sensor, and the others are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com