Unidirectional overrunning clutch gear shift mechanism

A technology that surpasses clutch and second gear. It is used in mechanical equipment, gear transmissions, components with teeth, etc., and can solve problems such as off-gear, flameout, engine lost rotation, and slow response to speed changes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

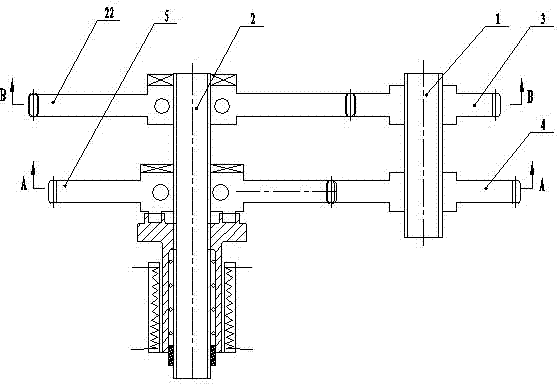

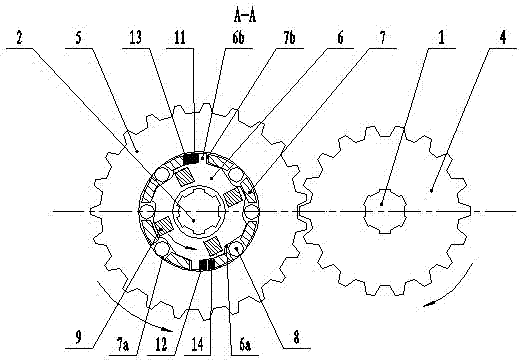

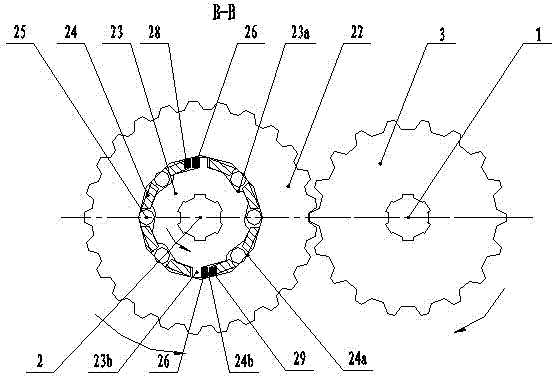

[0035] please join Figure 5 , Figure 6 , Figure 7 , Figure 14 and Figure 15: the second gear driven unidirectional device includes a second gear driven gear 5 meshing with the second gear driving gear 4, and the left part of the second gear driven gear 5 is mounted on the driven shaft 2 via a bearing, The center of the right part of the second gear driven gear 5 is equipped with a second gear driven cam 6, and the second gear driven cam 6 is looped on the driven shaft 2, and the second gear driven cam 6 and the second gear A second gear driven floating sleeve 7 is installed between the inner walls of the driven gear 5, and a group of second gear driven cam curved surfaces 6a and two second gear driven cams 6b are arranged on the outer circumference of the second gear driven cam 6. , the two second-gear driven cams 6b and the second-gear driven cam curved surface 6a are evenly distributed on the outer circumference of the second-gear driven cam 6, and the two second-ge...

Embodiment 2

[0037] please join Figure 8 , Figure 9 , Figure 10 , Figure 14 and Figure 15 : the second gear driven unidirectional device includes a second gear driven gear 5 meshing with the second gear driving gear 4, and the left part of the second gear driven gear 5 is mounted on the driven shaft 2 via a bearing, The center of the right part of the second gear driven gear 5 is equipped with a second gear driven cam 6, and the second gear driven cam 6 is looped on the driven shaft 2, and the second gear driven cam 6 and the second gear A second gear driven floating sleeve 7 is installed between the inner walls of the driven gear 5, and a group of second gear driven cam curved surfaces 6a and two second gear driven cams 6b are arranged on the outer circumference of the second gear driven cam 6. , the two second-gear driven cams 6b and the second-gear driven cam curved surface 6a are evenly distributed on the outer circumference of the second-gear driven cam 6, and the two second-...

Embodiment 3

[0039] please join Figure 11 , Figure 12 , Figure 13 , Figure 14 and Figure 15 : the second gear driven unidirectional device includes a second gear driven gear 5 meshing with the second gear driving gear 4, and the left part of the second gear driven gear 5 is mounted on the driven shaft 2 via a bearing, The center of the right part of the second gear driven gear 5 is equipped with a second gear driven cam 6, and the second gear driven cam 6 is looped on the driven shaft 2, and the second gear driven cam 6 and the second gear A second gear driven floating sleeve 7 is installed between the inner walls of the driven gear 5, and a group of second gear driven cam curved surfaces 6a and two second gear driven cams 6b are arranged on the outer circumference of the second gear driven cam 6. , the two second-gear driven cams 6b and the second-gear driven cam curved surface 6a are evenly distributed on the outer circumference of the second-gear driven cam 6, and the two secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com