Optimization method of spraying humidification system of direct air condenser

An air-cooled condenser and system optimization technology, applied in steam/steam condensers, direct contact heat exchangers, water shower coolers, etc. Unreasonable methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

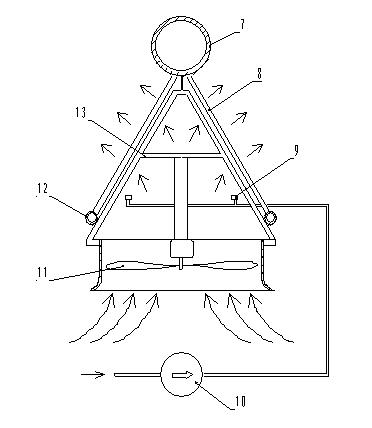

[0039] The composition of the spray humidification system in which the nozzles of the direct air-cooled condenser are arranged in a plane will be described in detail below in conjunction with the embodiments. The condenser of a direct air-cooled unit is composed of multiple air-cooled units. For example, the condenser of a 300MW direct air-cooled unit generally has 24 or 30 air-cooled units, and the condenser of a 600MW direct air-cooled unit generally has 56 or 64 air-cooled units. The structure and working principle of each air-cooling unit are the same, so the arrangement of atomizing nozzles in the spray humidification system of each air-cooling unit is the same, and it is only necessary to optimize and study the spray humidification system of a single air-cooling unit.

[0040] figure 1 It is a schematic diagram of the structure of the spray humidification system with direct air-cooled condenser and air-cooled single unit. In the spray humidification system, the nozzles ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com