Heat-relieving device for industrial emission

A heat-dissipating and industrial technology, applied in the field of industrial emission treatment devices, can solve problems such as thermal pollution that cannot be completely solved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

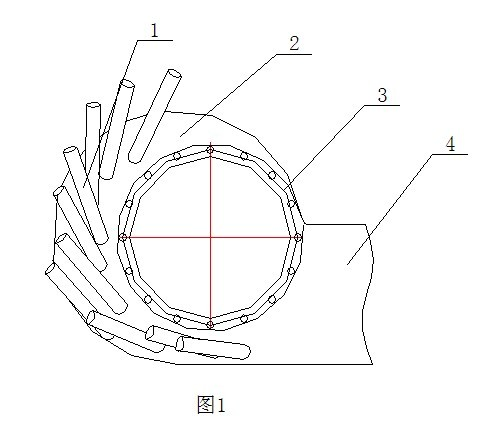

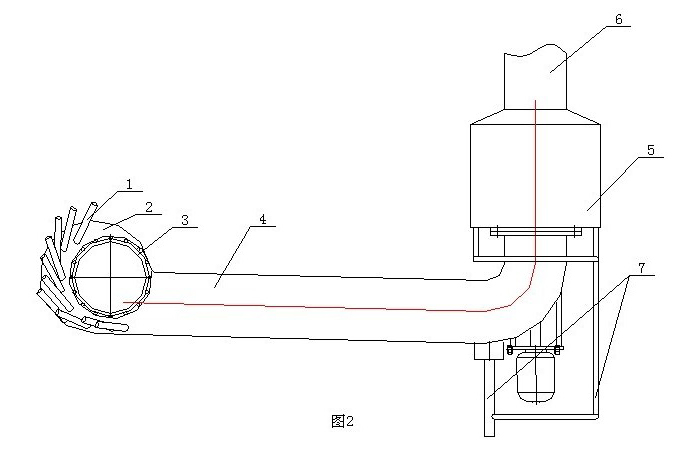

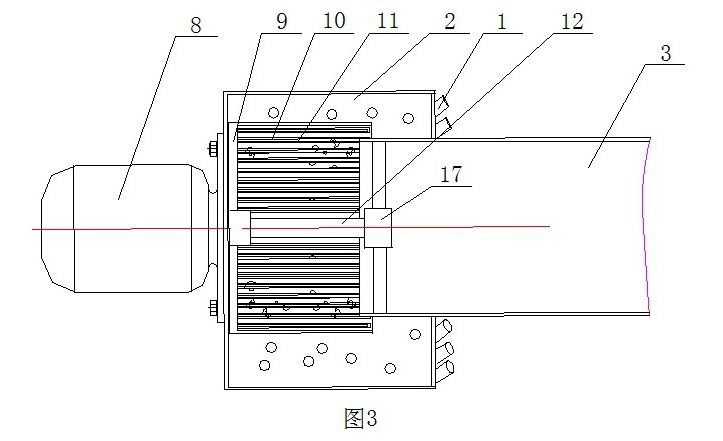

[0019] Such as figure 1 , figure 2 As shown, the present invention is a heat dissipation device for industrial discharge, which includes a casing 2 with a discharge pipe 3 and a discharge pipe 4, a motor 8 is fixedly installed on the side wall of the casing 2, and a motor 8 is fixed on the side wall of the discharge pipe. 3. A bearing 17 is fixedly installed inside, and the front end of the output shaft 12 of the motor 8 is inserted through the inner hole of the bearing 17, which can ensure the stability of the output shaft 12 of the motor 8 when it rotates. On the output shaft 12 of the motor 8, a wind wheel 9 with blades 10 on the side wall is fixedly installed. On the outer wall of the housing 2, a plurality of air guide pipes 1 communicating with the inner cavity of the housing 2 are arranged. When the wind wheel 9 When rotating, negative pressure will be generated in the inner cavity of the casing 2, so that the cold air from the outside is introduced into the casing 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com