Comprehensive detection method and device of tool tapered handle (7:24)

A comprehensive detection and taper shank technology, applied in the direction of measuring device, electromagnetic measuring device, electric device, etc., can solve the problems of low-efficiency single-piece small batch production, many inspection items, affecting inspection efficiency, etc., to simplify the structure, improve the Detection efficiency and accuracy, damage reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

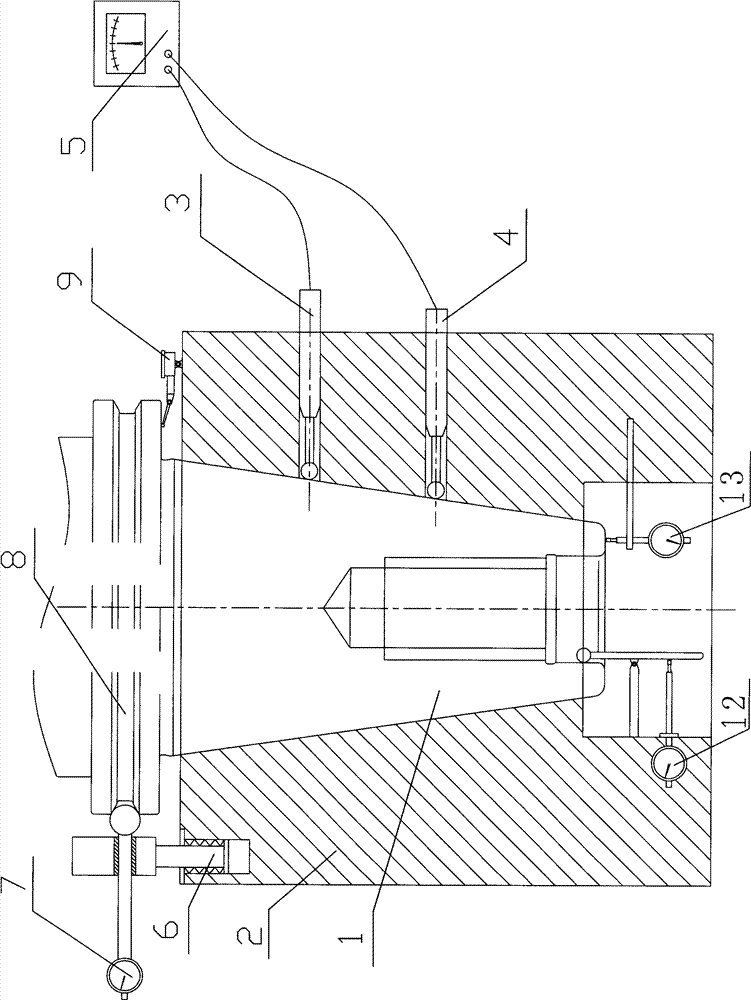

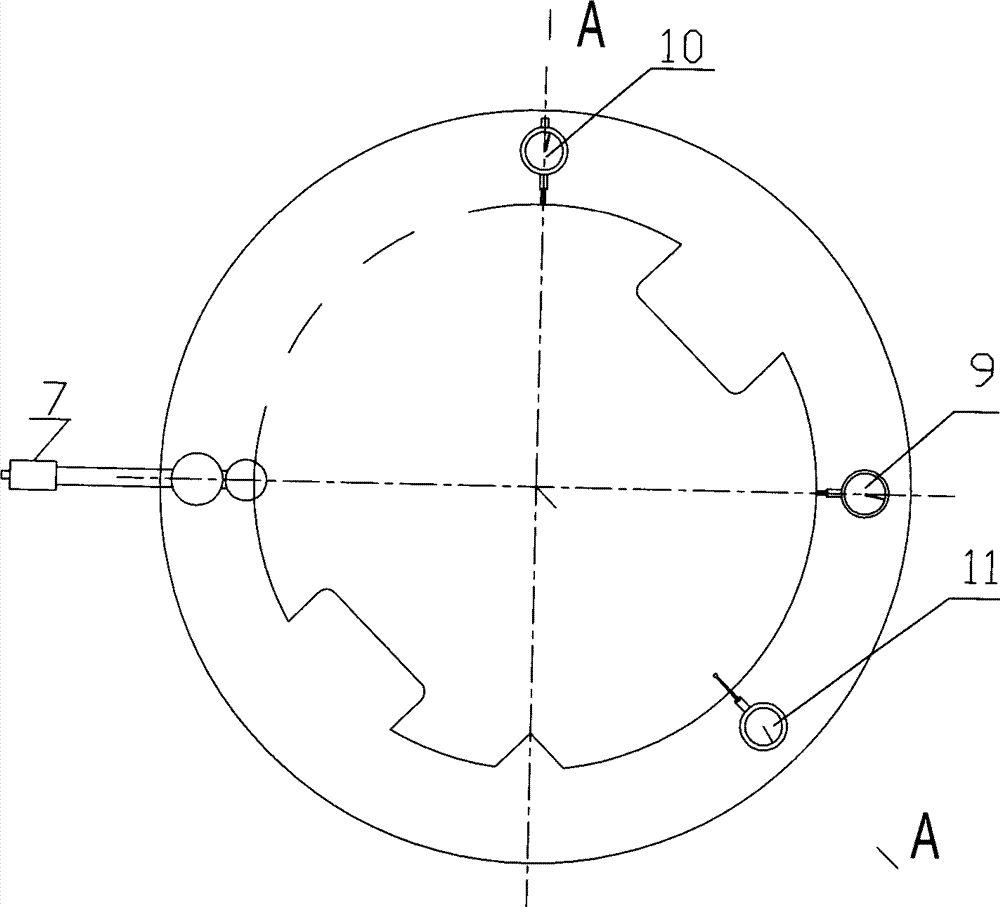

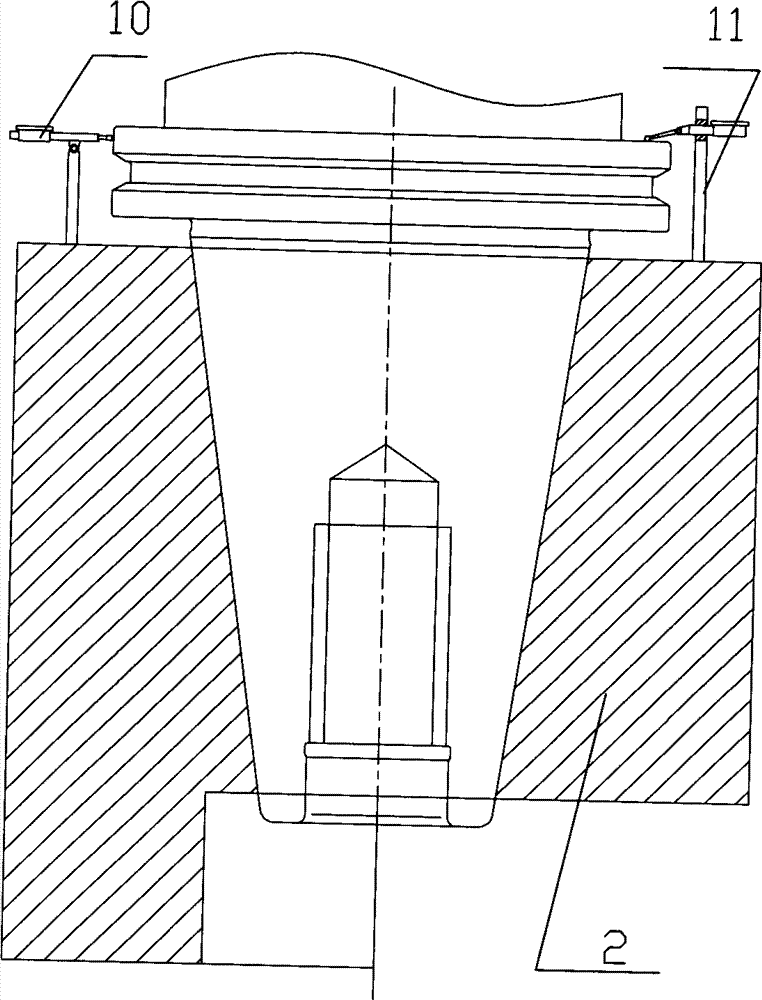

[0019] A 7:24 tool taper shank comprehensive detection device, which consists of: a base 2 with a taper hole 1, one side of the base 2 is equipped with a power-up sensor head 3 and a power-down sensor head 4, the The power-up sensor head 3 and the power-down sensor head 4 are connected to the comparator 5, and the upper end side of the base 1 is connected to the ball probe dial indicator 7 through the support 6, and the ball probe percentage indicator The meter 7 contacts the standard rod 8, the standard rod 8 contacts the lever swing meter 9, the upper end of the base 1 is equipped with an outer circle dial indicator 10 and a dial indicator 11, and the lower end of the base 1 is installed on one side. Tail hole jump, size dial indicator 12 are arranged, and cone length dial indicator 13 is equipped with on the other side of described pedestal lower end.

[0020] In the 7:24 tool taper shank comprehensive detection device, the outer circle dial indicator is installed at a posi...

Embodiment 2

[0022] A 7:24 tool taper shank comprehensive detection method. On a precisely processed base, the inductive probe for detecting the taper angle and outer cone roundness of the taper shank is fixed, the inductive probe is connected with the inductance comparator, and the measurement Indicators of other sizes and precisions are fixed by the mechanism, and then through the mechanism, the electrical probe and each indicator probe are in contact with the attached standard bar measurement surface, and the pointers of the comparator and each indicator are aligned to zero, and then the tested tool Put in the taper handle of the tool shank, and measure the taper angle error by reading the deviation of the inductance comparator; rotate the taper handle to measure the roundness of the probe through the pointer fluctuation range on the comparator; adjust other probes to make them match the taper handle The measured surface is in contact, and the value of the pointer’s deviation from the ze...

Embodiment 3

[0024] According to the 7:24 tool taper shank comprehensive detection method and device described in Embodiment 1, two adjustable upper and lower electrical probes are installed on a base with a 7:24 taper hole for use by a comparator. Measure the taper angle error and roundness of the 7:24 tool handle after zero calibration with a standard rod, and the accuracy can reach 0.1 μm; pass the lever swing meter, ball probe dial indicator, and dial indicator with a standard rod for zero calibration. 3.2±0.1, 11.1±0.1, 19.1 0 -0.1 , ∮72.3±0.05 (SK40 handle, or SK50 handle ∮107.25±0.05) four important dimensions; through the outer circle dial indicator with a standard rod to zero, the test standard stipulates the flange outer circle size and runout; through the cone length percentage The test standard stipulates the length and end face runout of the taper shank after zero calibration with a standard rod; the test standard specifies the diameter size and runout of the taper shank pull...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com