Capacitive sensor and actuator

A capacitive sensor and actuator technology, applied in the direction of converting sensor outputs, instruments, and using electromagnetic/magnetic devices to transmit sensing components, can solve the problems of unfavorable sensors or actuators, difficult realization of size, etc., and achieve simple realization and realization. Geometric shapes, effects that simplify use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

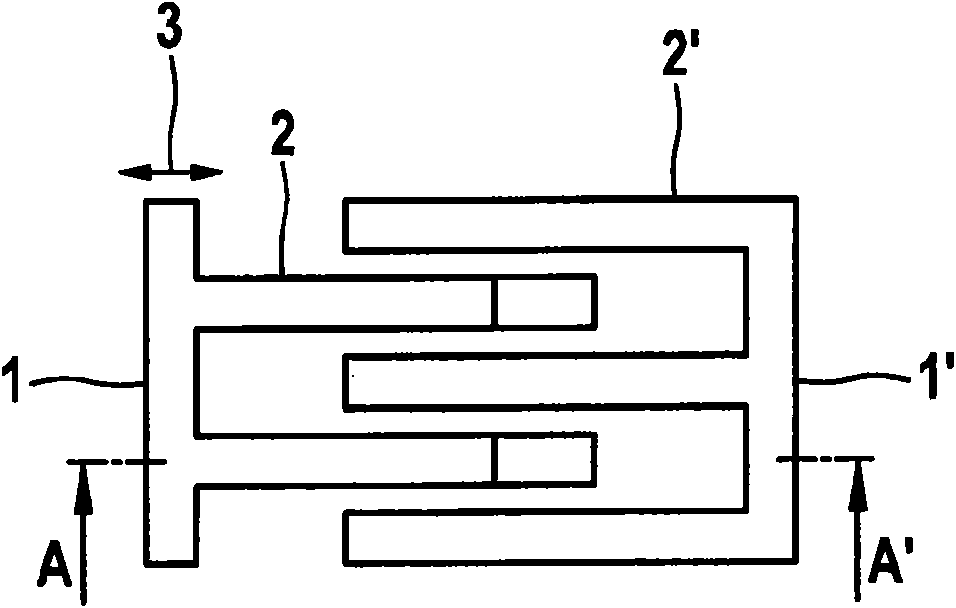

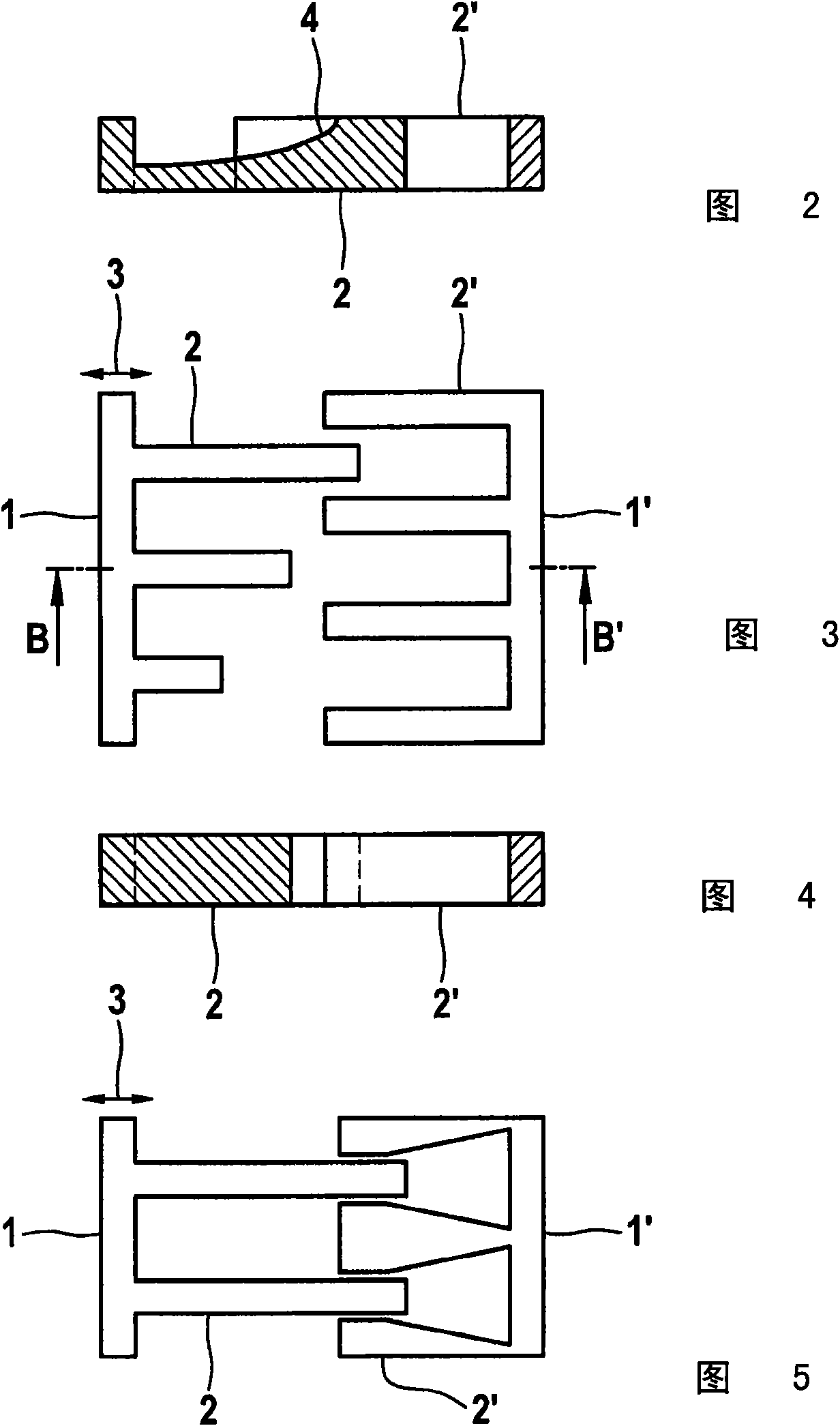

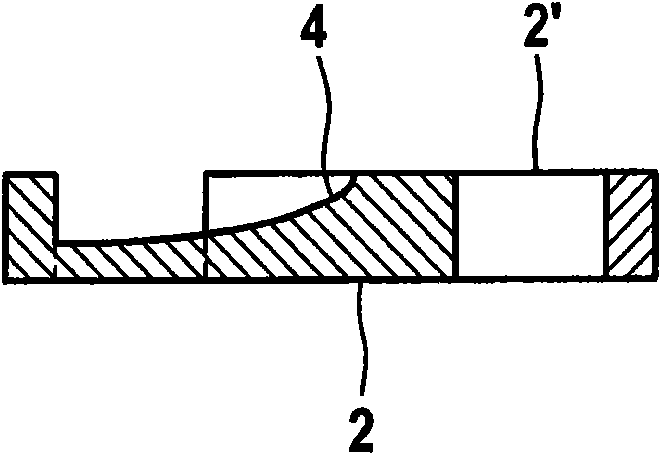

[0024] according to figure 1 The capacitive sensor comprises a not shown oscillating mass which is fixed deflectably on an immovable substrate or, for example, on another movable mass. The deflectability of the oscillating mass can be achieved by fastening it to the base with one or more springs of defined stiffness. Furthermore, a first comb electrode 1 with a plurality of comb teeth 2 is fastened to this oscillating mass, a second comb electrode 1 with a plurality of comb teeth 2' is fastened to a substrate or another movable mass. Electrode 1'. Comb teeth 2 and 2 ′ of comb electrodes 1 and 1 ′ are aligned parallel to one another and engage in one another in a comb-like manner such that they form overlapping regions in the rest state. The comb teeth 2 and 2' thus create a capacitor, wherein the overlapping area is the area that contributes to the capacitance of the capacitor.

[0025] Furthermore, the comb electrodes 1 and 1' are fastened on the oscillating mass or substr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com