White-light organic electroluminescent device and preparation method thereof

An electroluminescent device and electroluminescent technology, which are applied in the fields of electro-solid devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve problems such as affecting the luminous efficiency of devices, and achieve the effects of excellent device performance and excellent color stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

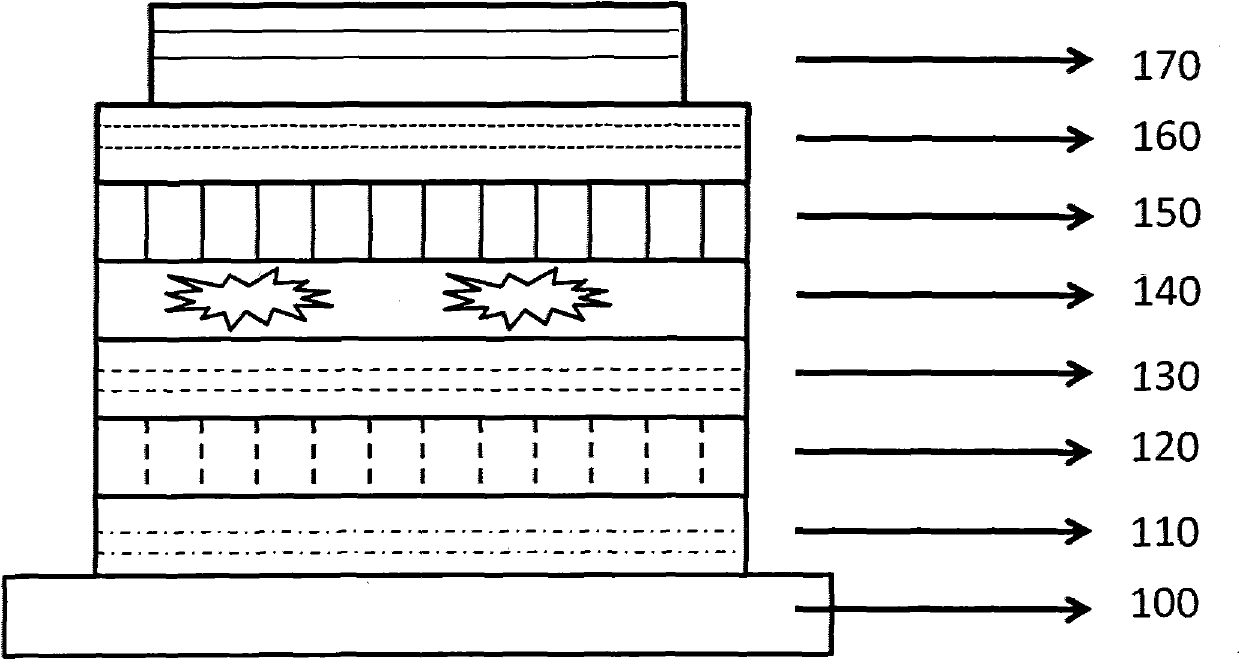

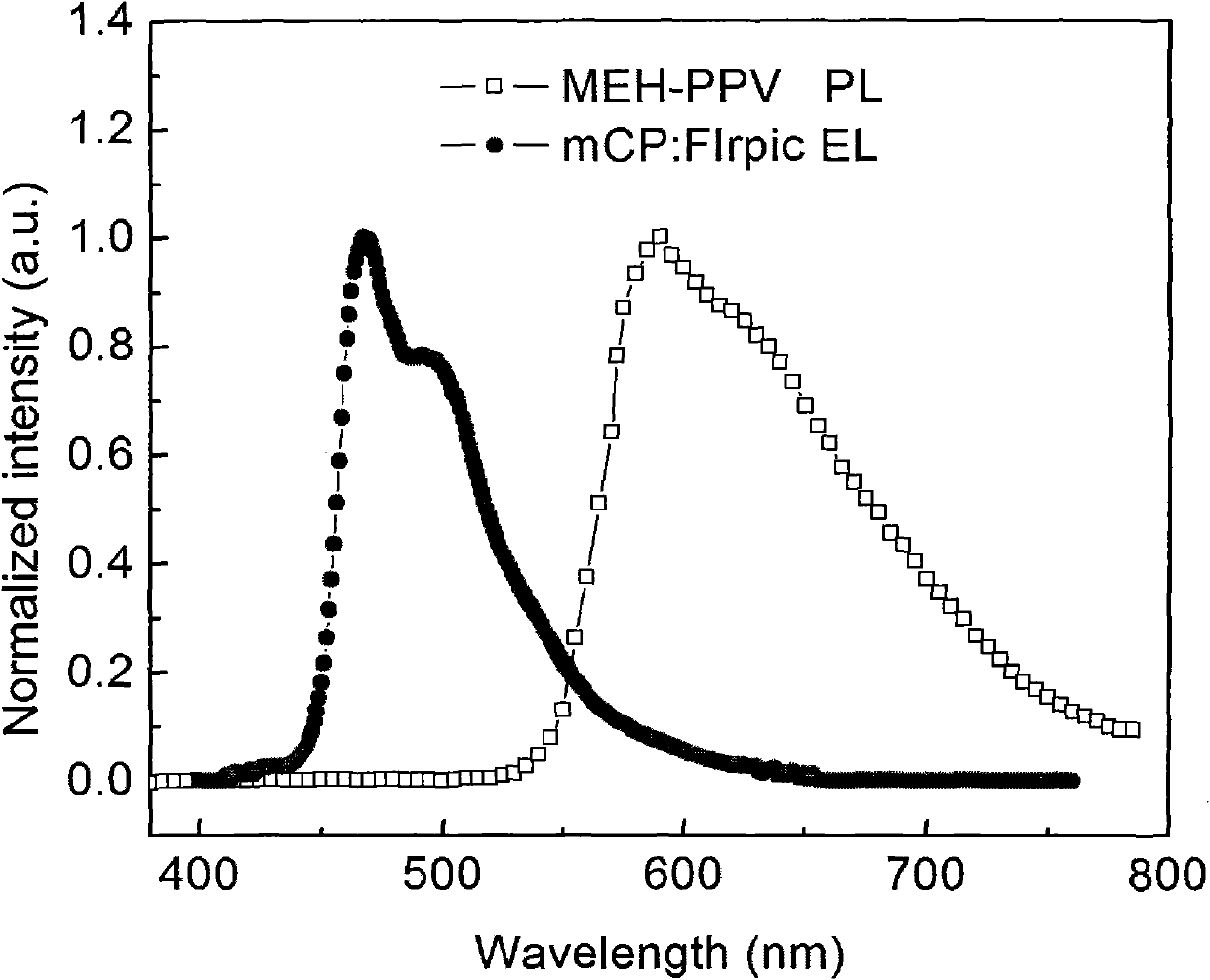

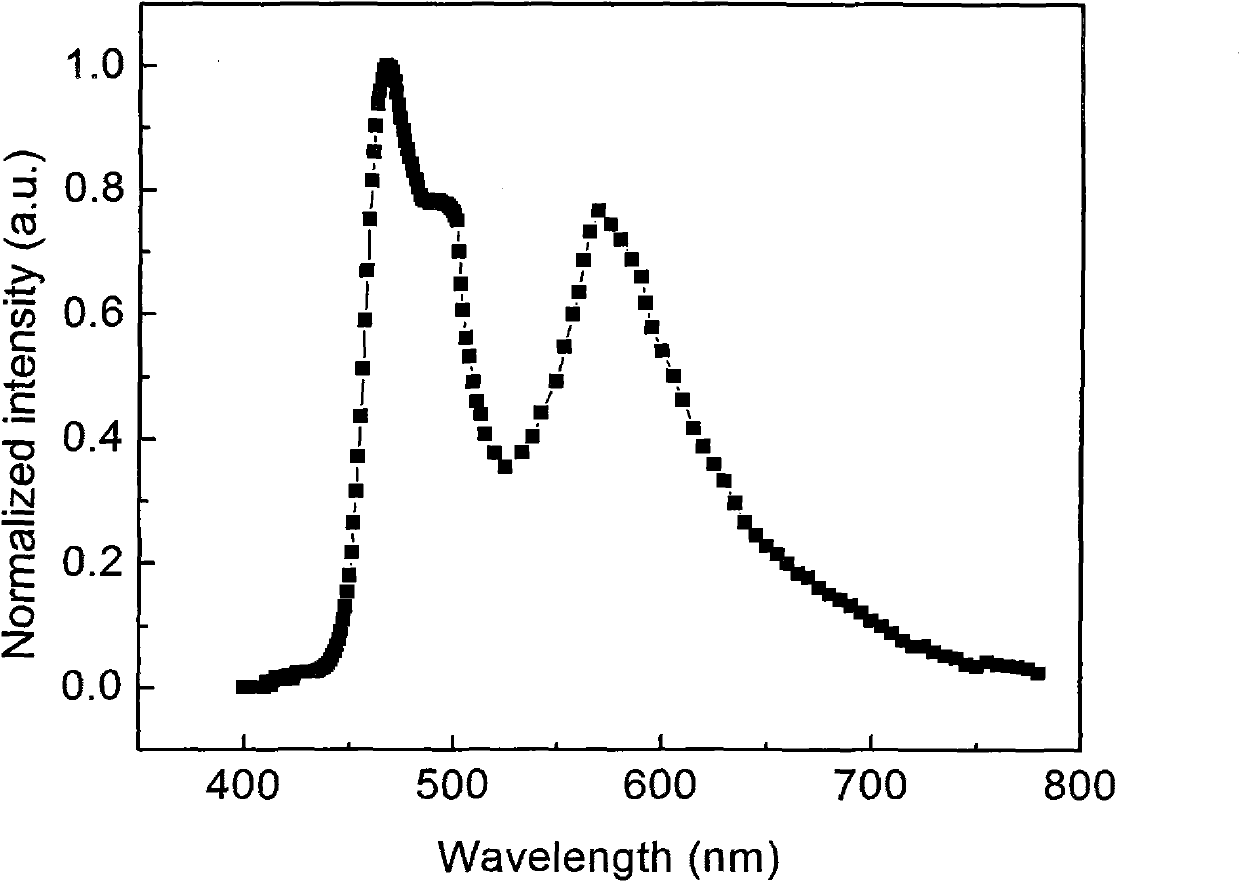

[0067] like figure 1 As shown, the substrate 100 of the device is a glass substrate, the first electrode layer 110 is an anode, 120 is a hole injection layer, 130 is a hole transport layer, the light emitting layer in the structure of the device is 140, and the electron transport layer is 150 , the electron injection layer is 160, and the cathode layer is 170.

[0068] The material of the hole injection layer of the device is MEH-PPV, the material of the hole transport layer is NPB, the material of the light emitting layer is FIrpic doped with mCP, the material of the electron transport layer is TPBi, and the material of the electron injection is Alq 3 , The cathode layer is made of Mg:Ag alloy. The entire device structure is described as:

[0069] Glass substrate / ITO / MEH-PPV(100nm) / NPB(30nm) / mCP: FIrpic(20nm) / TPBi(20nm) / Alq 3 (30nm) / Mg:Ag(100nm)

[0070] The preparation method is as follows:

[0071] ①Use detergent, ethanol solution and deionized water to ultrasonically ...

Embodiment 2

[0079] like figure 1 As shown, the substrate 100 of the device is a flexible substrate, the first electrode layer 110 is an anode, 120 is a hole injection layer, 130 is a hole transport layer, the light emitting layer in the structure of the device is 140, and the electron transport layer is 150 , the electron injection layer is 160, and the cathode layer is 170.

[0080] The flexible substrate of the device is PET, the material of the hole injection layer is MEH-PPV, the material of the hole transport layer is NPB, the blue phosphorescent material FIrpic doped mCP is selected for the light emitting layer, the material of the electron transport layer is TPBi, and the electron injection material is selected as Alq 3 , The cathode layer is made of Mg:Ag alloy. The entire device structure is described as:

[0081] Flexible substrate / ITO / MEH-PPV(100nm) / NPB(30nm) / mCP: FIrpic(20nm) / TPBi(20nm) / Alq 3 (30am) / Mg:Ag(100nm)

[0082] The preparation method is as follows:

[0083] ①Us...

Embodiment 3

[0091] like figure 1 As shown, the substrate 100 of the device is a flexible substrate, the first electrode layer 110 is a polymer conductive anode, 120 is a hole injection layer, 130 is a hole transport layer, the light emitting layer in the structure of the device is 140, and the electron transport The layer is 150, the electron injection layer is 160, and the cathode layer is 170.

[0092] The polymer conductive anode of the device is PANI, the material of the hole injection layer is MEH-PPV, the material of the hole transport layer is NPB, the blue phosphorescent material FIrpic is doped with mCP for the light emitting layer, the material of the electron transport layer is TPBi, and the electron injection material is selected for Alq 3 , The cathode layer is made of Mg:Ag alloy. The entire device structure is described as:

[0093] Flexible substrate / PANI / MEH-PPV(100nm) / NPB(30nm) / mCP: FIrpic(20nm) / TPBi(20nm) / Alq 3 (30nm) / Mg:Ag(100nm)

[0094] The preparation method is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com