Method for preparing slab waveguide laser device in neodymium-doped lutecium vanadate crystal

A strip waveguide and laser device technology, which is applied in the field of optoelectronic device preparation, achieves the effects of high controllability, low cost and strong arbitrariness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

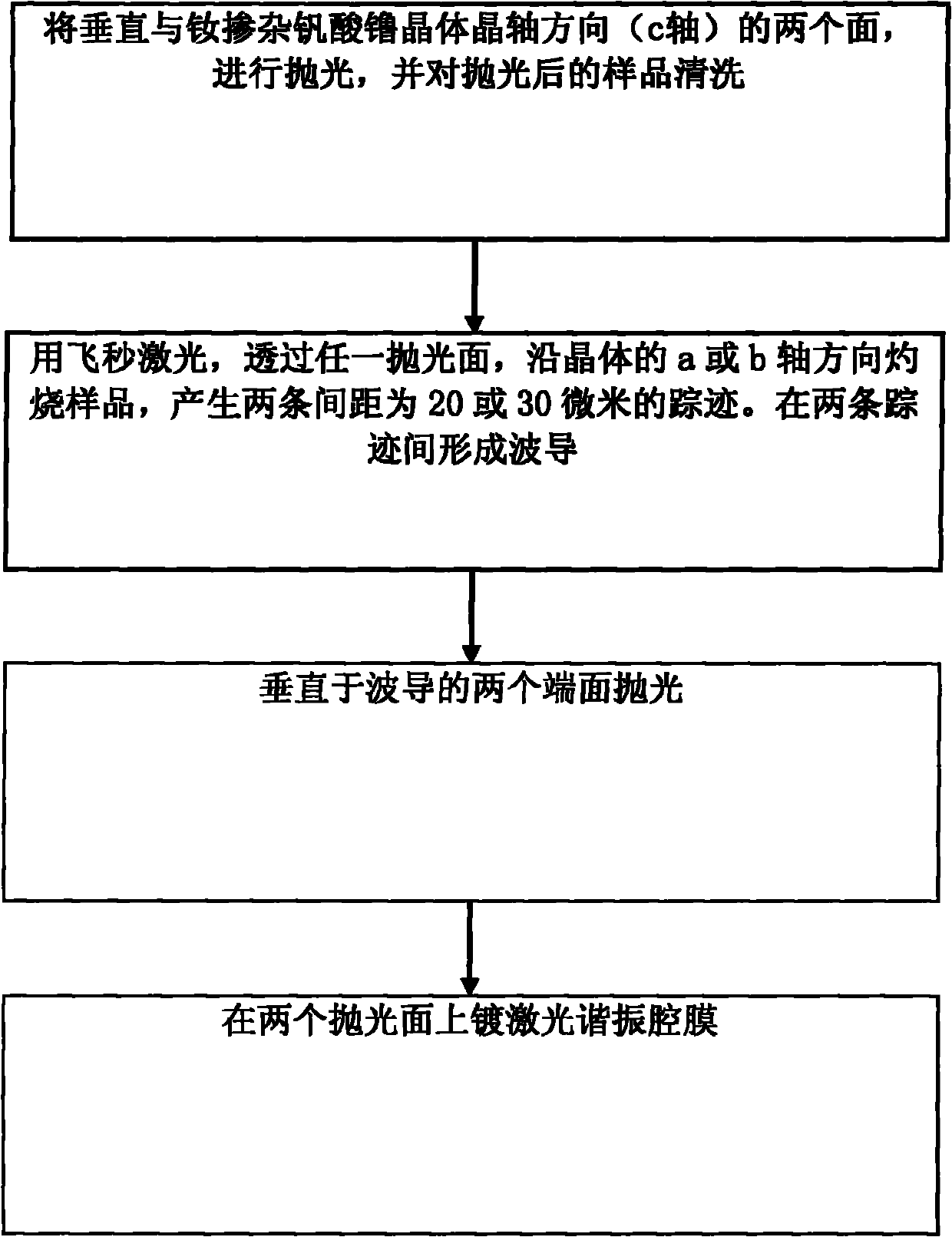

[0014] Embodiment 1: Method for preparing strip waveguide laser device in neodymium-doped lutetium vanadate crystal

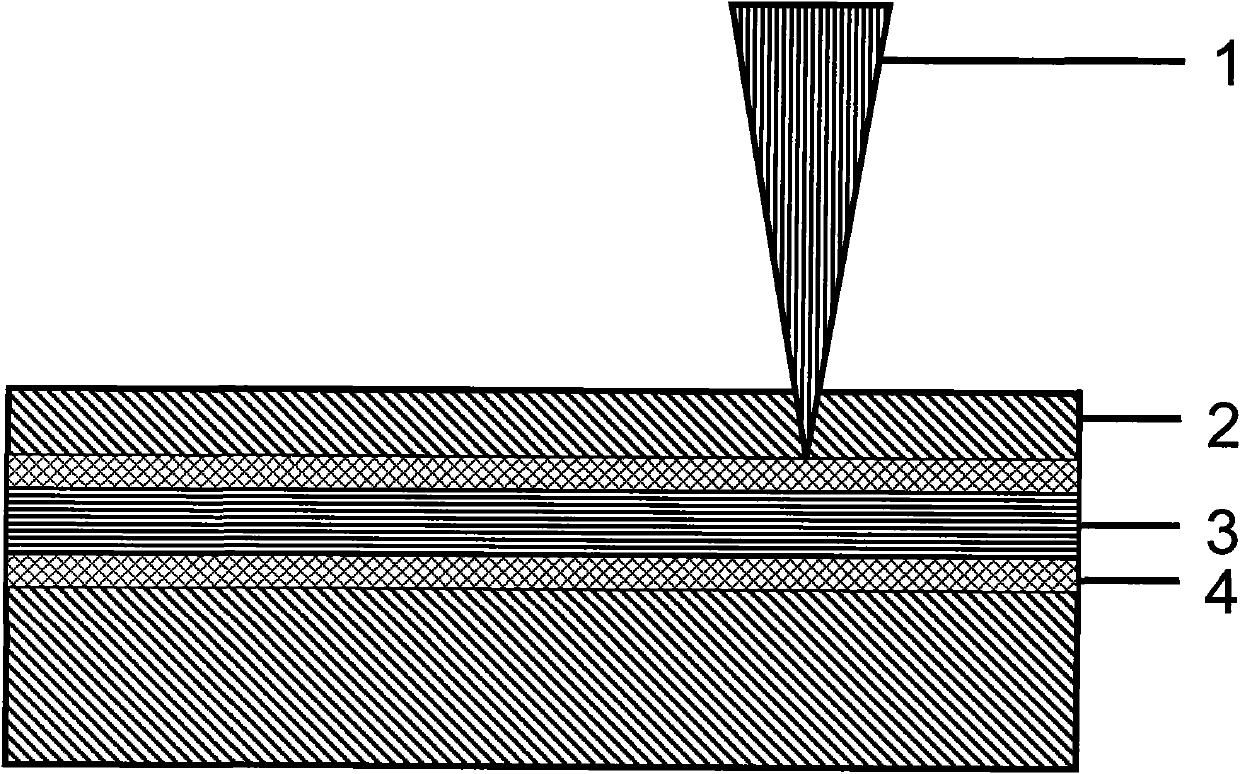

[0015] 1) Polishing the two surfaces perpendicular to the crystal axis direction (c-axis) of the neodymium-doped lutetium vanadate crystal (2), and cleaning the polished sample;

[0016] 2) Use a femtosecond laser (1) to burn the sample along the a-axis direction of the crystal through any polished surface to produce two traces with a distance of 30 microns. A strip waveguide (3) is formed between the two traces. Use a femtosecond laser (1) with a pulse repetition frequency of 200 kHz, an energy of 8 microjoules / pulse, a femtosecond laser with a writing speed of 1 mm / s, a wavelength of 1047 nm, and a pulse width of 350 femtoseconds.

[0017] 3) Polishing the two end faces of the crystal perpendicular to the direction of the strip waveguide.

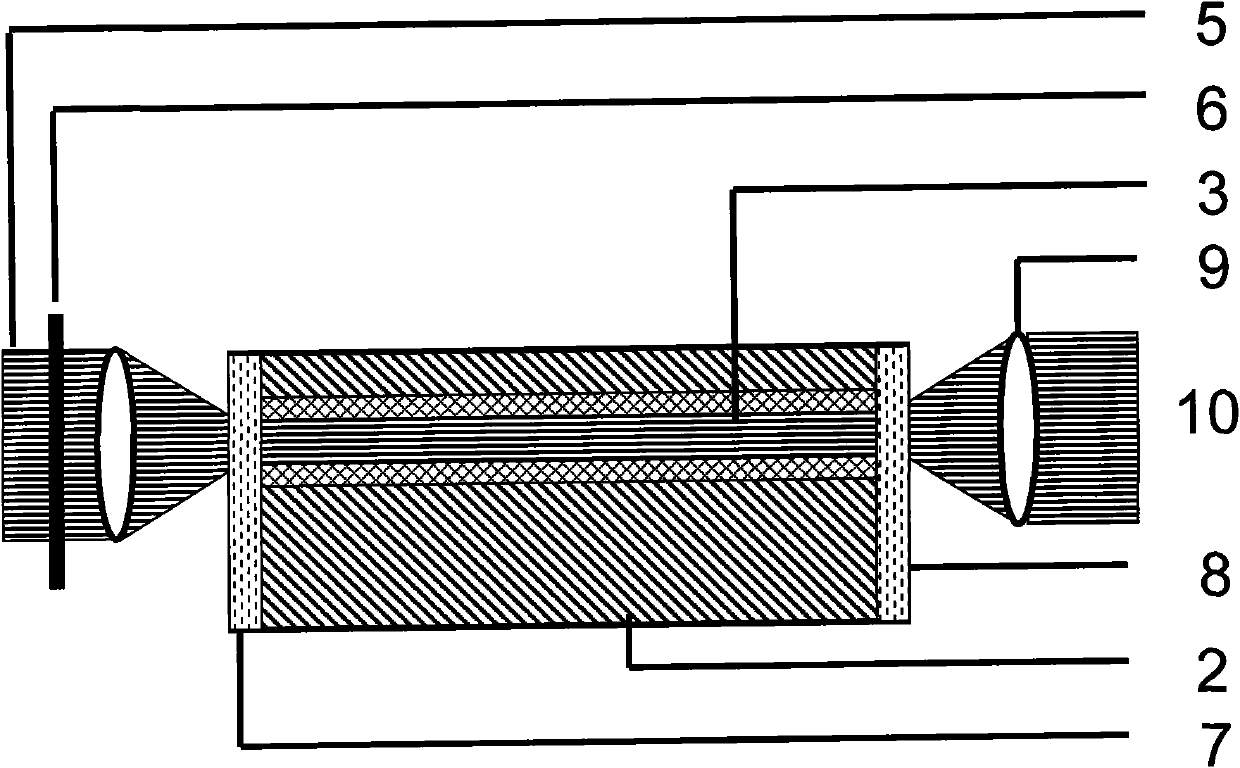

[0018] 4) Coating the laser cavity film (7, 8) on the polished end face. The resonant cavity film in the direction of...

Embodiment 2

[0020] Embodiment 2: Method for preparing strip waveguide laser device in neodymium-doped lutetium vanadate crystal

[0021] 1) Polishing the two surfaces perpendicular to the crystal axis direction (c-axis) of the neodymium-doped lutetium vanadate crystal (2), and cleaning the polished sample;

[0022] 2) Use a femtosecond laser (1) to burn the sample along the a-axis direction of the crystal through any polished surface to produce two traces with a distance of 30 microns. A strip waveguide (3) is formed between the two traces. Use a femtosecond laser (1) with a pulse repetition frequency of 200 kHz, an energy of 9 microjoules / pulse, a writing speed of 2 mm / s, a wavelength of 1047 nm, and a pulse width of 350 femtoseconds.

[0023] 3) Polishing the two end faces of the crystal perpendicular to the direction of the strip waveguide.

[0024] 4) Coating the laser cavity film (7, 8) on the polished end face. The resonant cavity film in the direction of passing light is require...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com