Collagen ecological enzyme produced from plant straws and domestic wastes

A plant straw and ecological enzyme technology, applied in animal feed, animal feed, applications, etc., can solve the problems of plant straw and domestic waste that are difficult to deal with, and effective elements are difficult to use scientifically, so as to reduce feeding costs, save food and feed, and taste Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

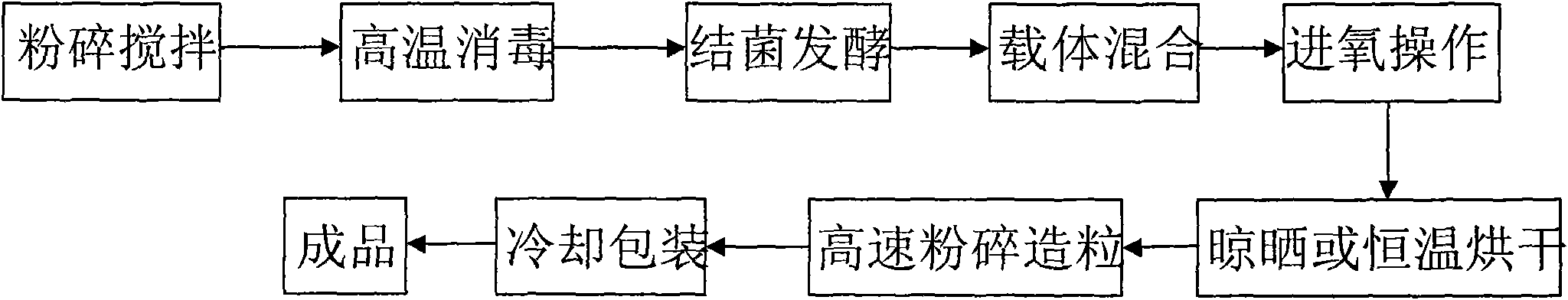

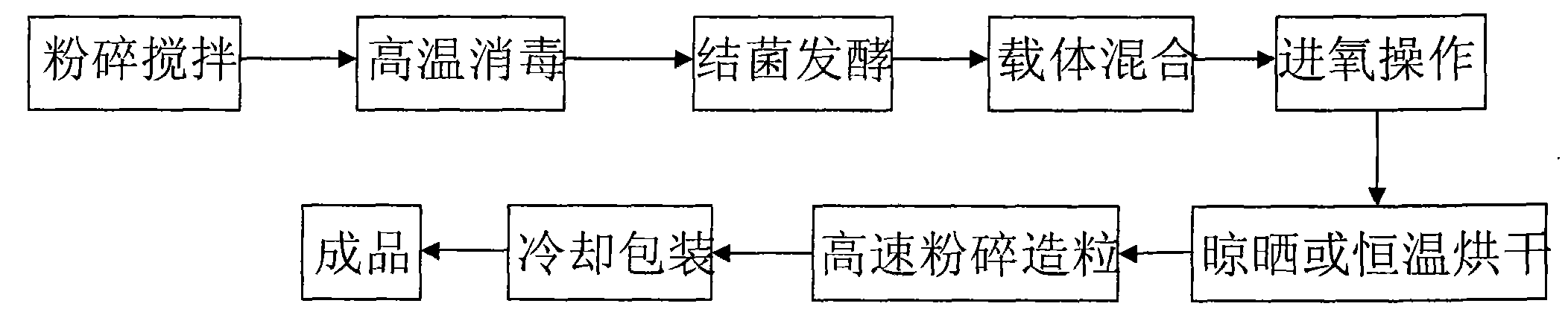

[0007] Referring to the accompanying drawings, it is a process flow chart of the present invention, and the process is as follows: in the early stage, after pulverizing waste oils and fats, meat offcuts, waste bones, and meat miscellaneous cypress, stir them into a water paste, and carry out high-temperature disinfection. After cooling, nodules are fermented (time: 2 days in summer and 5-7 days in winter. The temperature is kept above 16 degrees). In the later stage, after the fermentation is completed, stir and mix with straw powder, chaff powder, soybean hulls, volatile powder, and corn hulls in a ratio of 2:1 to continue fermentation. The fermentation room and temperature are kept at a balance. The temperature is about 18 degrees and the time is 3 days in summer. , 5 days in winter. Then oxidize and mix, the temperature is about 40 degrees, 3 times in a row, and the temperature is about 58 degrees when oxygen is mixed. After the fermentation is completed, it is air-dried a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com