Laser cleaning equipment and method for sol-gel membrane surface

A technology for cleaning equipment and gel films, applied in cleaning methods and appliances, chemical instruments and methods, etc., can solve problems such as physical injury of operators, damage of components with low threshold value, degradation of optical beam quality, etc., to achieve obvious cleaning effect and process Controllable and reproducible results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

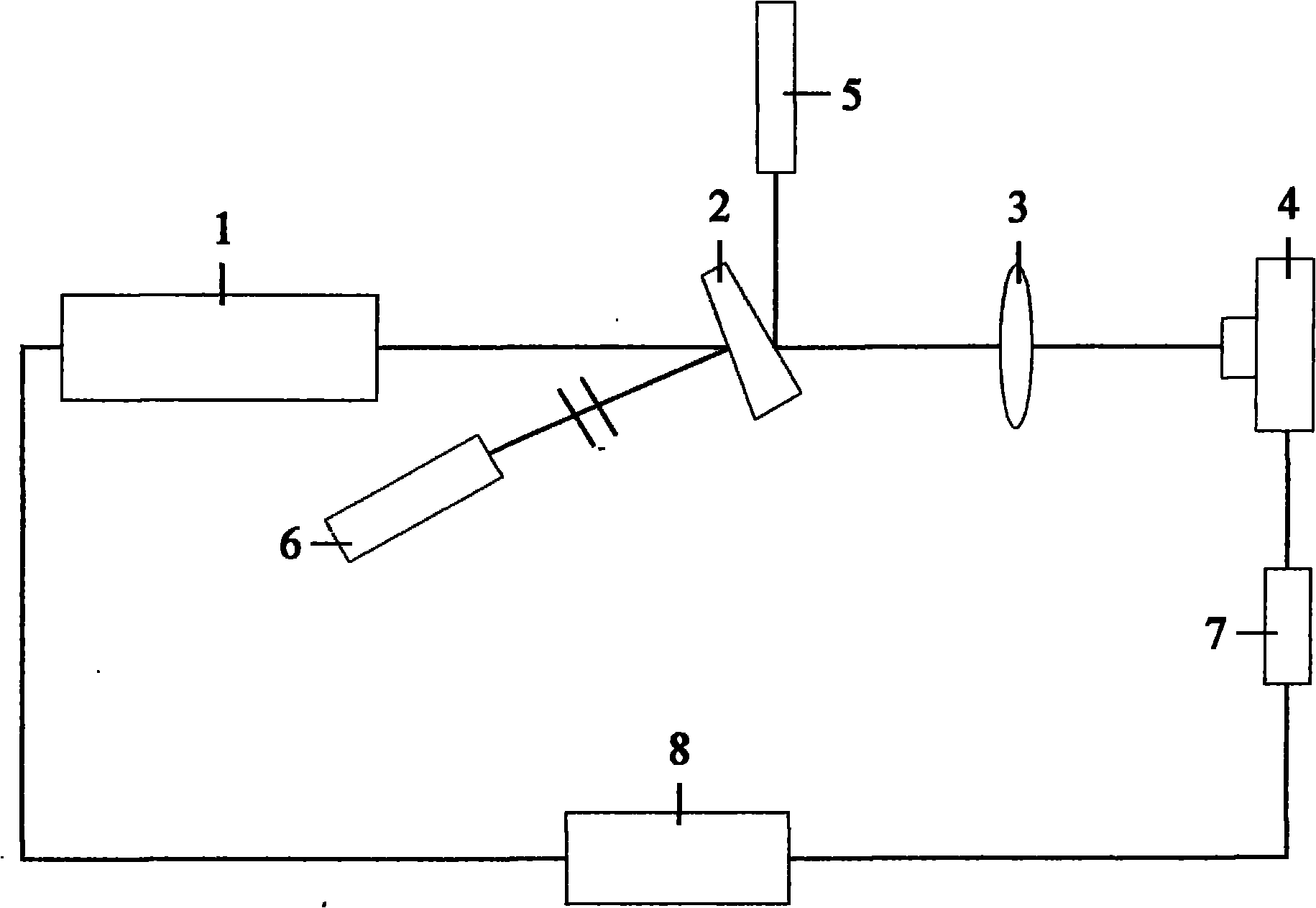

[0022] Such as figure 1 As shown, the sol-gel film surface laser cleaning equipment includes a pulsed laser 1, a splitting plate 2, a lens 3, a two-dimensional mobile platform 4, a collimated laser 5, an energy meter 6, a stepping motor 7 and a computer 8; On the two-dimensional mobile platform 4, the computer 8 is respectively connected with the pulse laser 1 and the stepping motor 7 through cables, and the computer controls the pulse laser 1 and the stepping motor 7, and the stepping motor 7 controls the two-dimensional mobile platform 4; the pulse laser 1 excites The focused high-energy pulse laser is sufficient to induce air optical breakdown. The pulse laser can be Nd:YAG (Nd-doped yttrium aluminum garnet) laser, XeF (xenon fluoride) excimer laser, etc., which are controlled by computer 8 through cables; The pulsed laser light emitted by the pulsed laser 1 is divided into two beams after splitting the plate 2. One beam enters the energy meter 6 and is called probe light; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com