Single trailing arm suspension deceleration type wheel electric drive system

A technology of electric drive system and single trailing arm, applied in the direction of suspension, elastic suspension, motion deposition, etc., can solve the problems of low power density, large volume, large mass, etc., and achieve the reduction of unsprung mass and compact structure Conciseness and the effect of improving handling stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

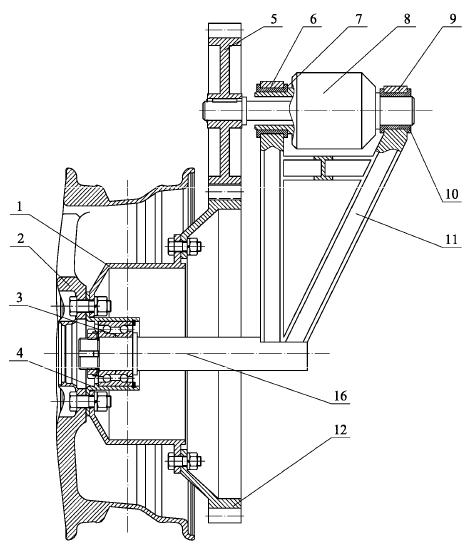

[0024] Please refer to the accompanying drawings for a further description of the present invention.

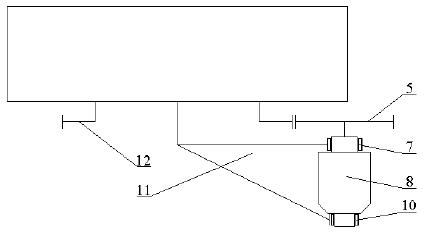

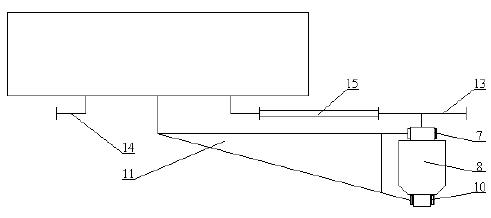

[0025] Such as figure 1 As shown, the present invention uses a gear transmission mode and is equipped with a drum brake as an example. Other transmission modes and systems equipped with disc brakes only need to be slightly modified on this basis, and will not be elaborated here.

[0026] Such as figure 1 As shown, the pinion 5 is installed on the output shaft of the motor through a flat key, and the large gear 12 obtains power by meshing with the pinion 5 . Bull gear 12 is installed on the brake drum 1 by several bolts, and brake drum 1, wheel hub 4 and rim 2 are fixed together by bolts, and bull gear 12 just can drive wheel like this. The inner ring of the hub 4 is supported by the outer ring of the hub bearing 3 , and the inner ring of the hub bearing 3 is supported by the axle 16 and the axle portion of the single trailing arm suspension swing arm 11 . The wheel hub bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com