Automatic gearshift device of electric vehicle

A technology of electric vehicles and electric motors, applied in the direction of electromechanical devices, electric vehicles, electric components, etc., can solve the problems of energy waste of batteries, large impact of batteries and controllers, small range of motor torque changes, etc., to achieve a high degree of automation, The effect of expanding the applicable area and facilitating high-speed operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below is that the present invention will further describe embodiment in conjunction with accompanying drawing:

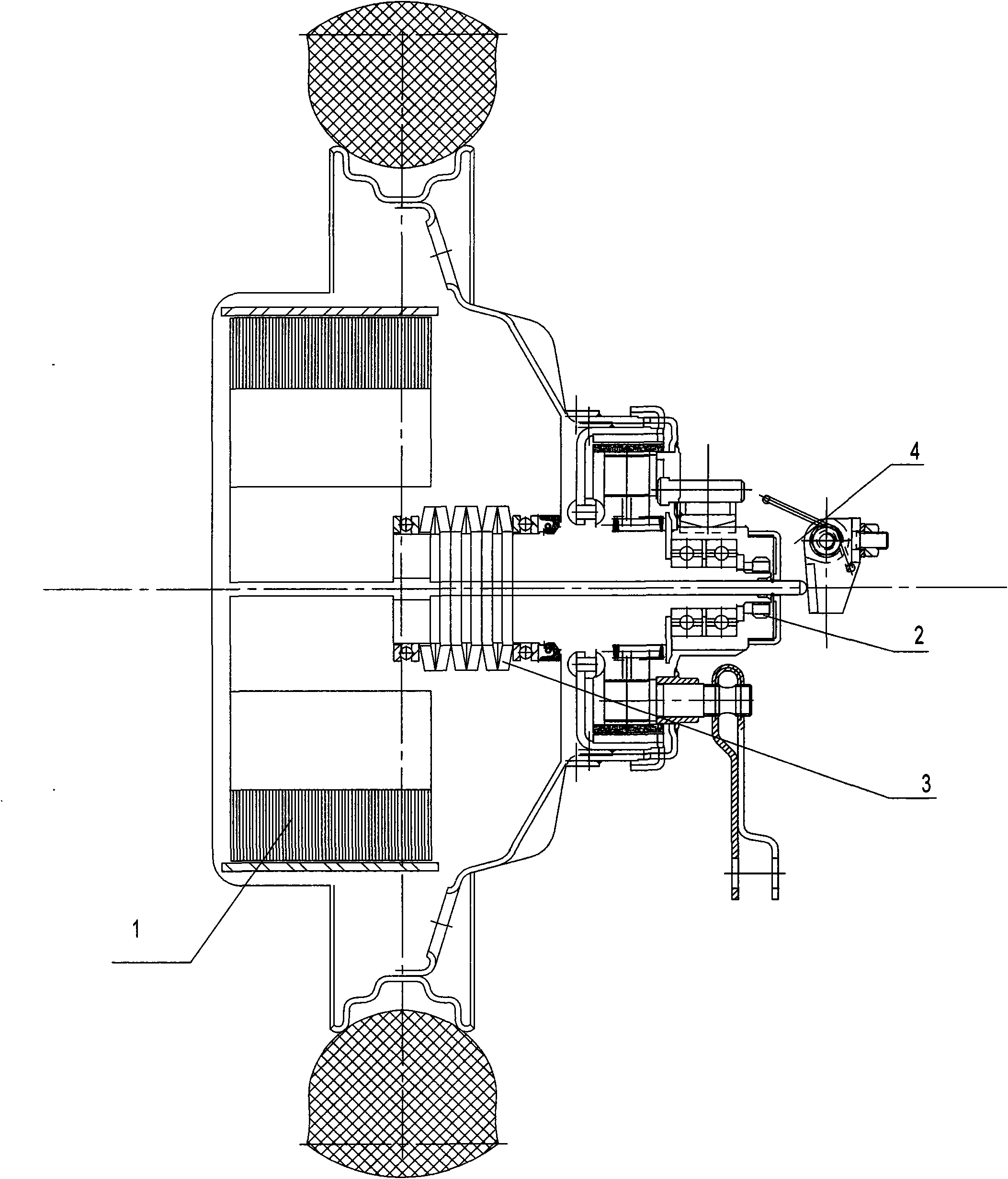

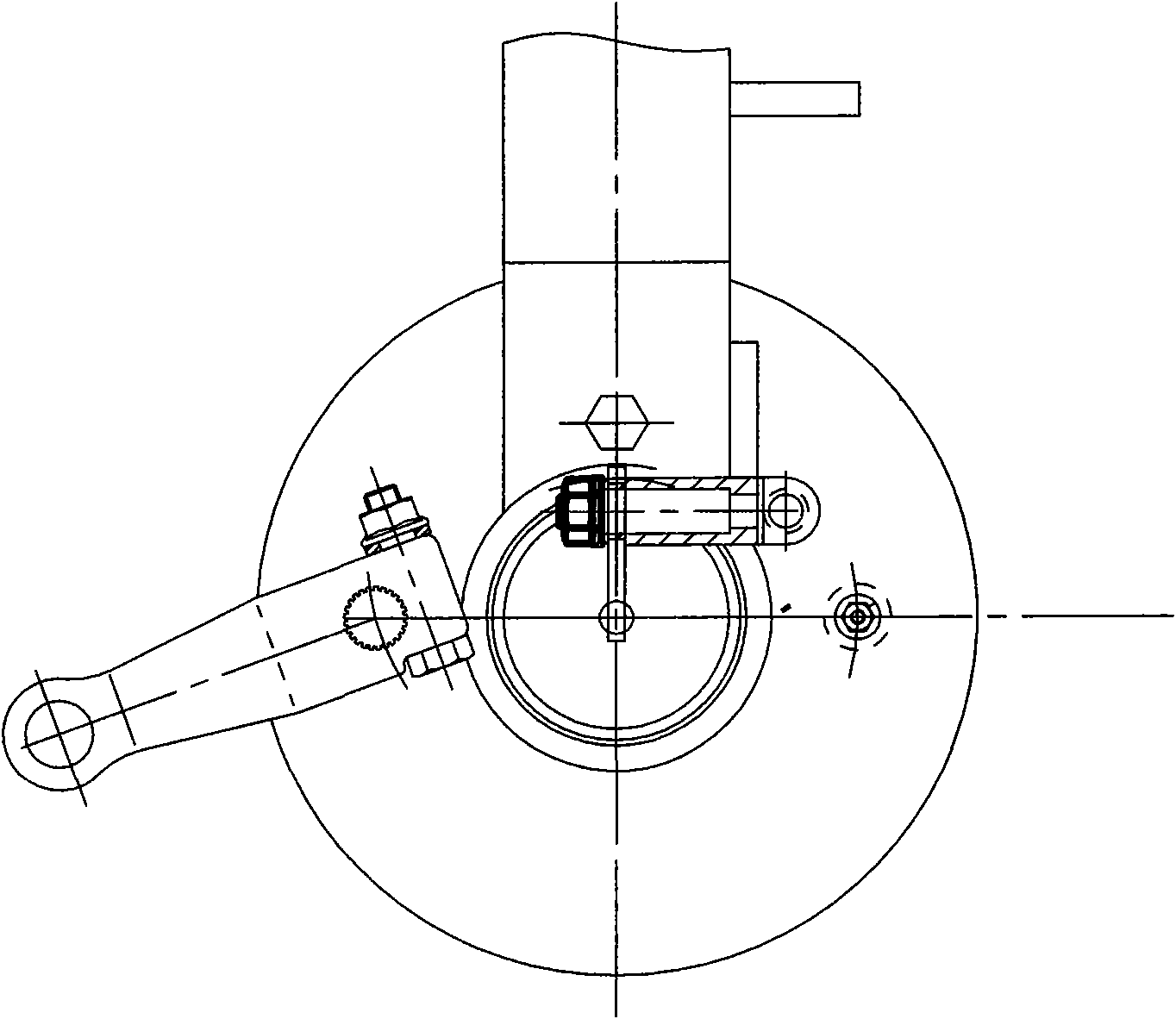

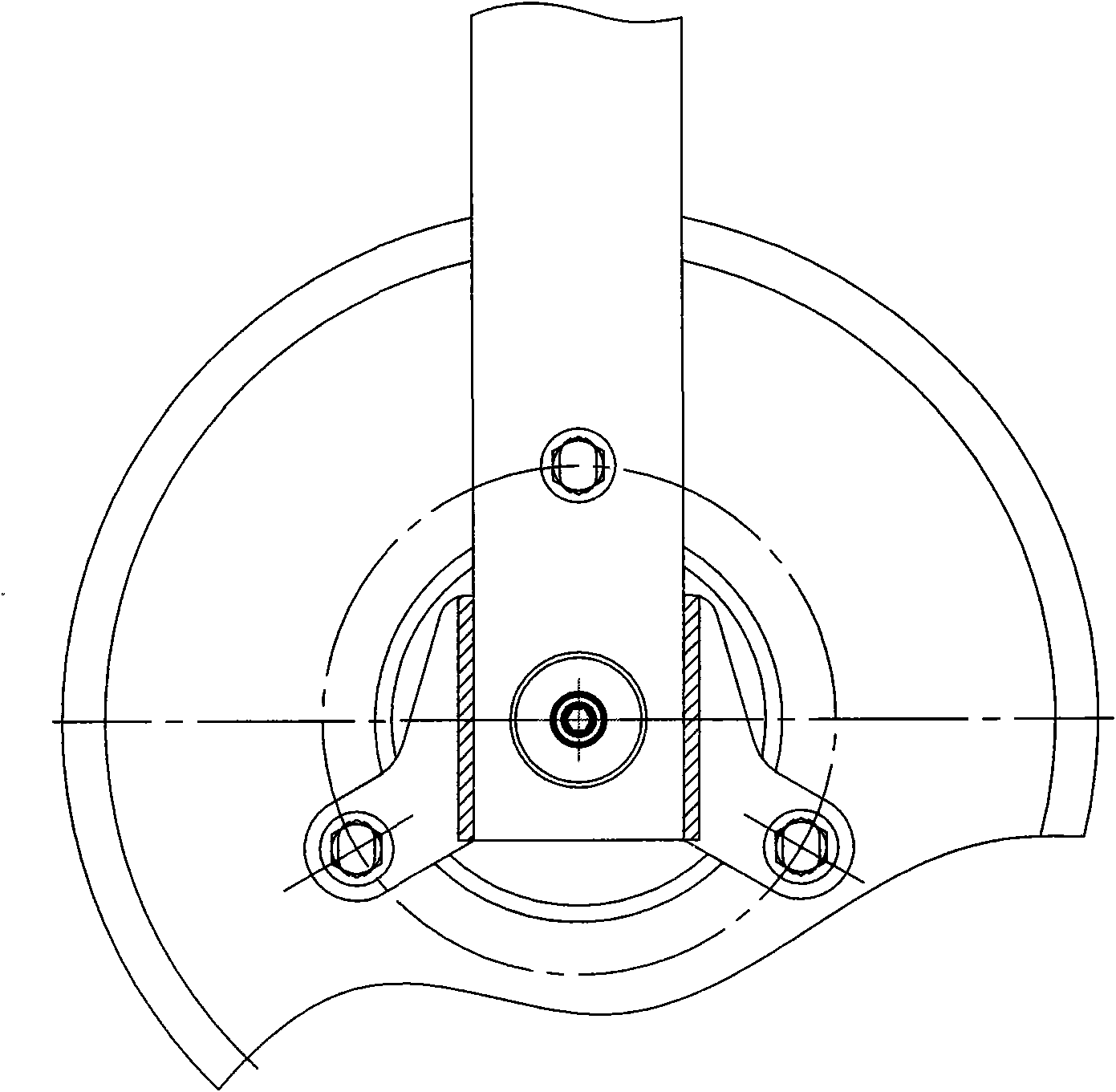

[0025] Figure 1 ~ Figure 3 As shown, the present invention is composed of a motor 1, a tower transmission gear 2, a disc spring 7, an adaptive disc spring cam differential transmission sensing mechanism 3, an adaptive cam speed change mechanism 4, a wheel hub 5 and a tire 6, etc. to form an electric vehicle transmission transmission. Sensitive automatic transmission shift drive. The motor adopts a brushless self-adaptive motor, and a closed-loop system is realized through the motor 1, the tower transmission gear 2, the self-adaptive dish spring cam differential transmission sensor mechanism 3, and the self-adaptive cam speed change mechanism 4. (HALL is S41F, magnetic steel 35H, enameled wire QZ130 / 2) First, the Hall handle gives the motor 1 a signal to energize and rotate to drive the tower transmission gear 2 to rotate, and the tower transmission gear 2 d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com