Brine refining process for removing calcium and magnesium by one step

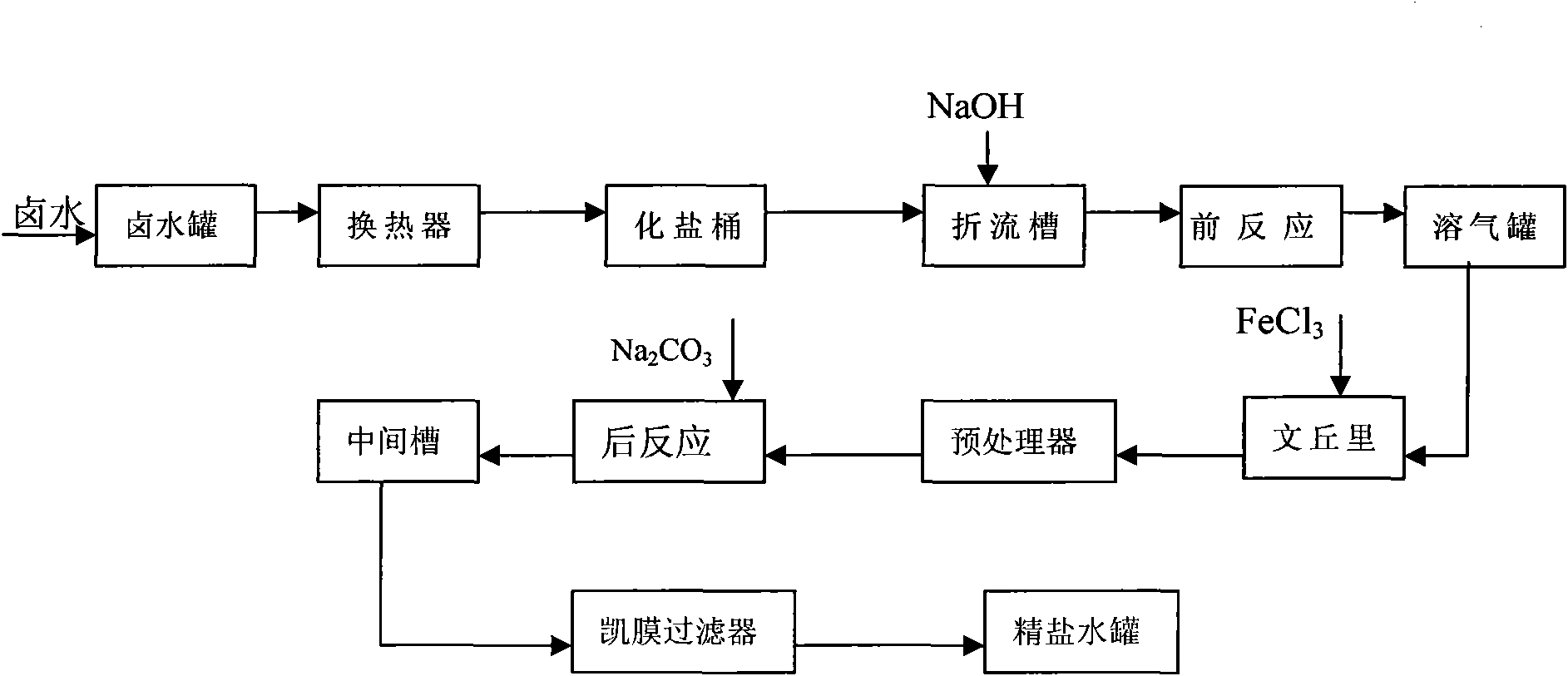

A brine refining, calcium and magnesium technology, applied in the direction of alkali metal halide purification, etc., can solve the problems of long process flow, large floor area, and many inspection personnel, so as to simplify the process flow, reduce consumption and equipment maintenance costs, Reduce the effect of inspectors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

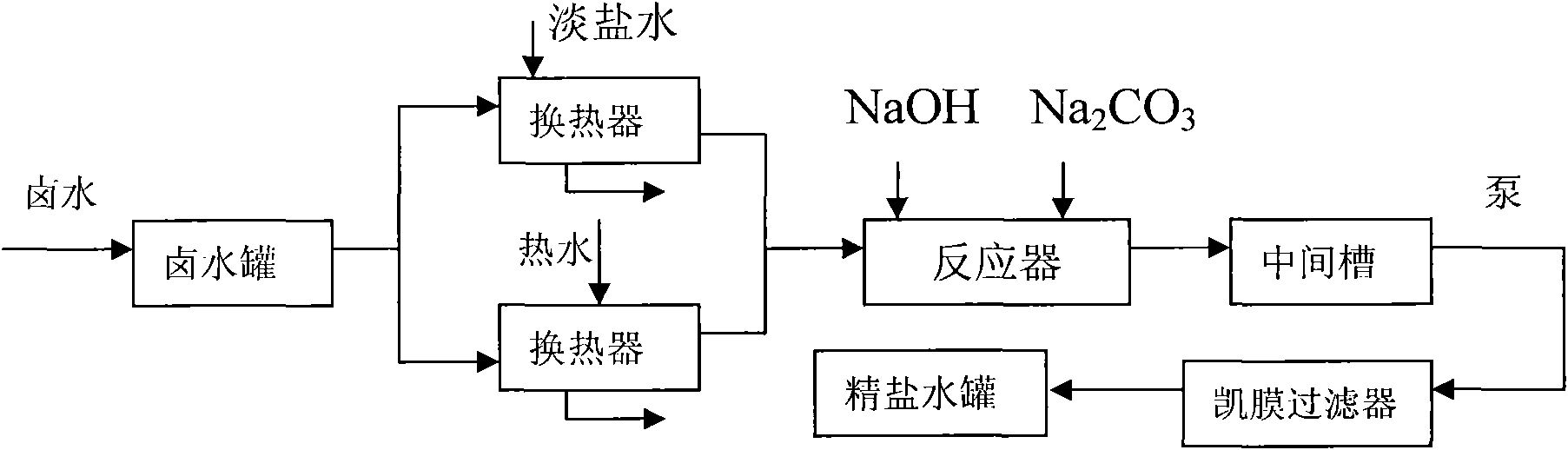

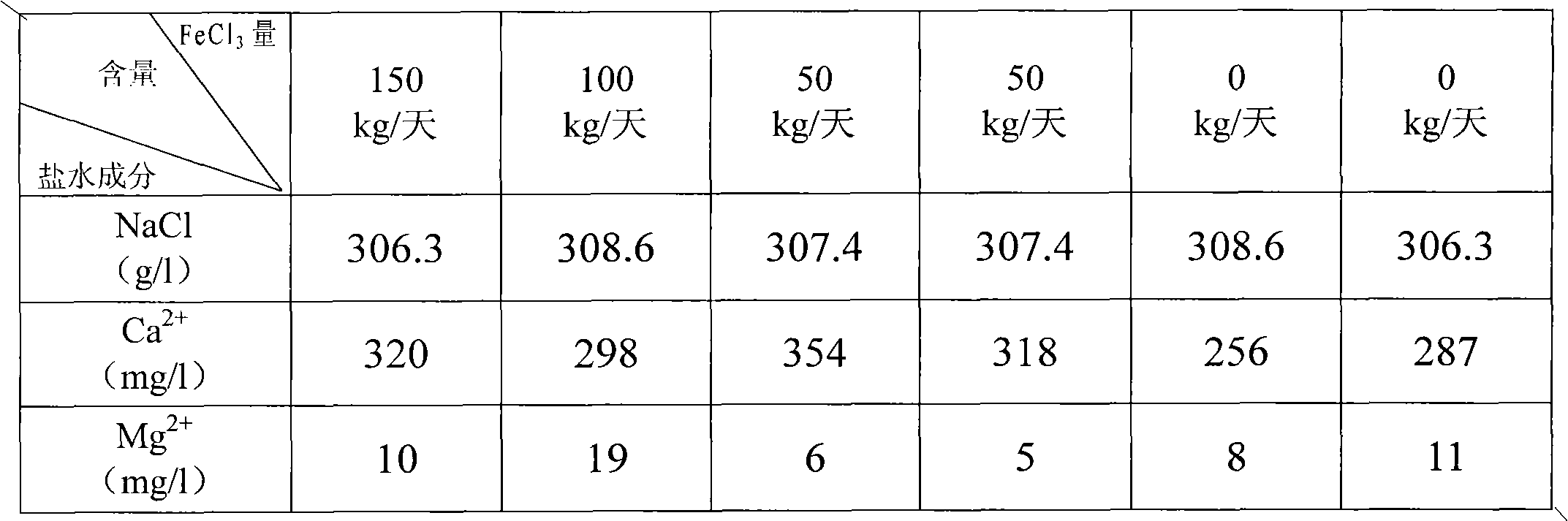

[0028] One-step brine refining process for calcium and magnesium removal, such as figure 2 As shown, taking the average production value of one month as an example, the process includes the following steps:

[0029] The first step is to pump out the saturated brine in the brine tank with a flow rate of 230m 3 / h, one way to exchange heat with dechlorinated light brine, and one way to exchange heat with hot water of synthesis furnace, so that the brine temperature can be preheated to 45-60°C;

[0030] In the second step, the brine preheated in the first step enters the reactor, and NaOH and NaOH are added to the reactor. 2 CO 3 , some of which NaOH and Na 2 CO 3 Wastewater from chlor-alkali production process; refining reaction to remove Mg in brine 2+ and Ca 2+ Afterwards, the NaOH concentration in the brine is 0.2-0.5g / L, and the NaOH 2 CO 3 The concentration is 0.3~0.5g / L, and then flows into the middle tank by itself;

[0031] The third step is to use the inlet pu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com