Method for increasing production capacity of acrylonitrile or methacrylonitrile

A technology of methacrylonitrile and high production capacity, which is applied in the preparation of hydrocarbon ammoxidation, organic chemistry, etc., can solve the problems of large investment and high difficulty of on-site construction, and achieve reduced construction strength, good technical effects and economic benefits, and simple construction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

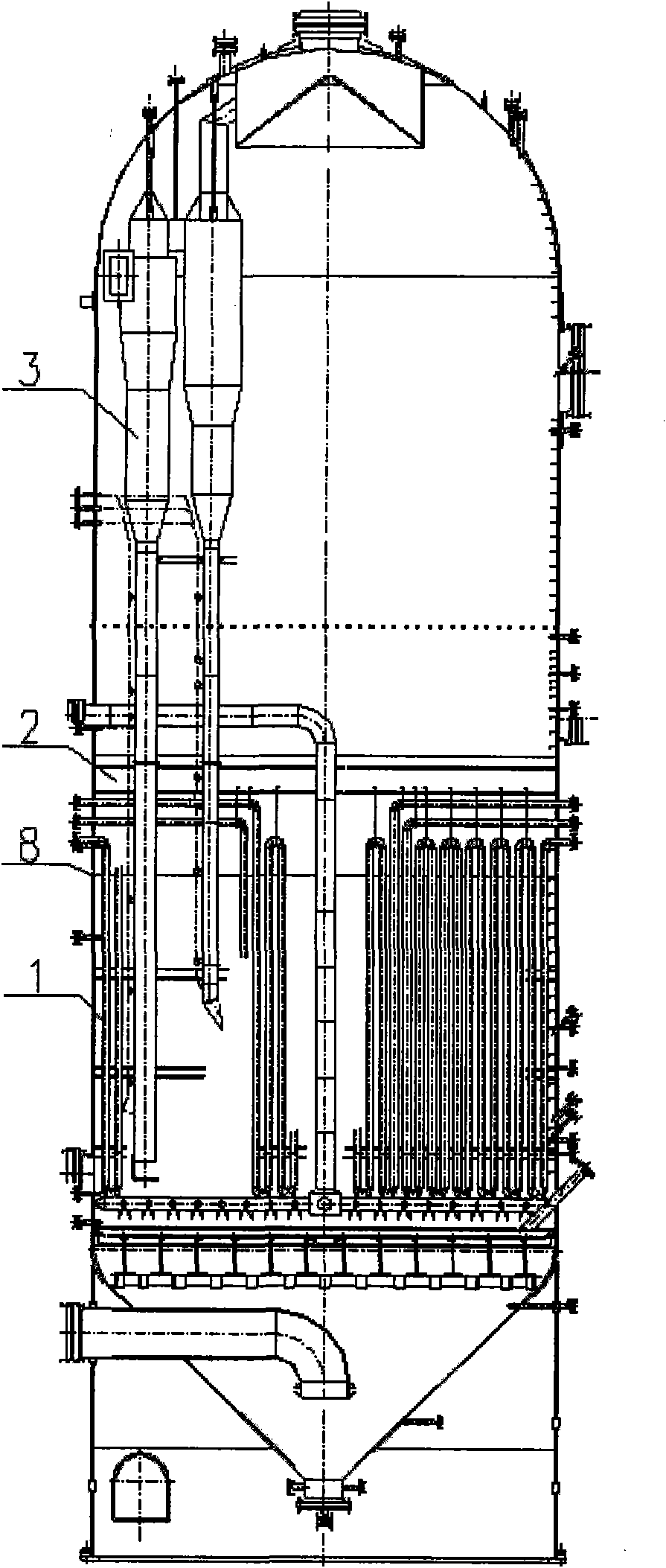

[0032] A set of acrylonitrile (or methacrylonitrile) production equipment adopts the propylene ammoxidation method, and the raw material gas enters the fluidized bed reaction from the bottom with the ratio of propylene (or isobutylene): ammonia: air = 1: 1: 9.8 (mol) The reaction temperature is 430°C, the pressure is 0.15MPa (absolute pressure), the catalyst is molybdenum-bismuth catalyst, and the heat of reaction is recycled with soft water to generate high-pressure steam. After the reaction, the gas can be washed, absorbed and rectified to obtain high-purity acrylonitrile or methacrylonitrile.

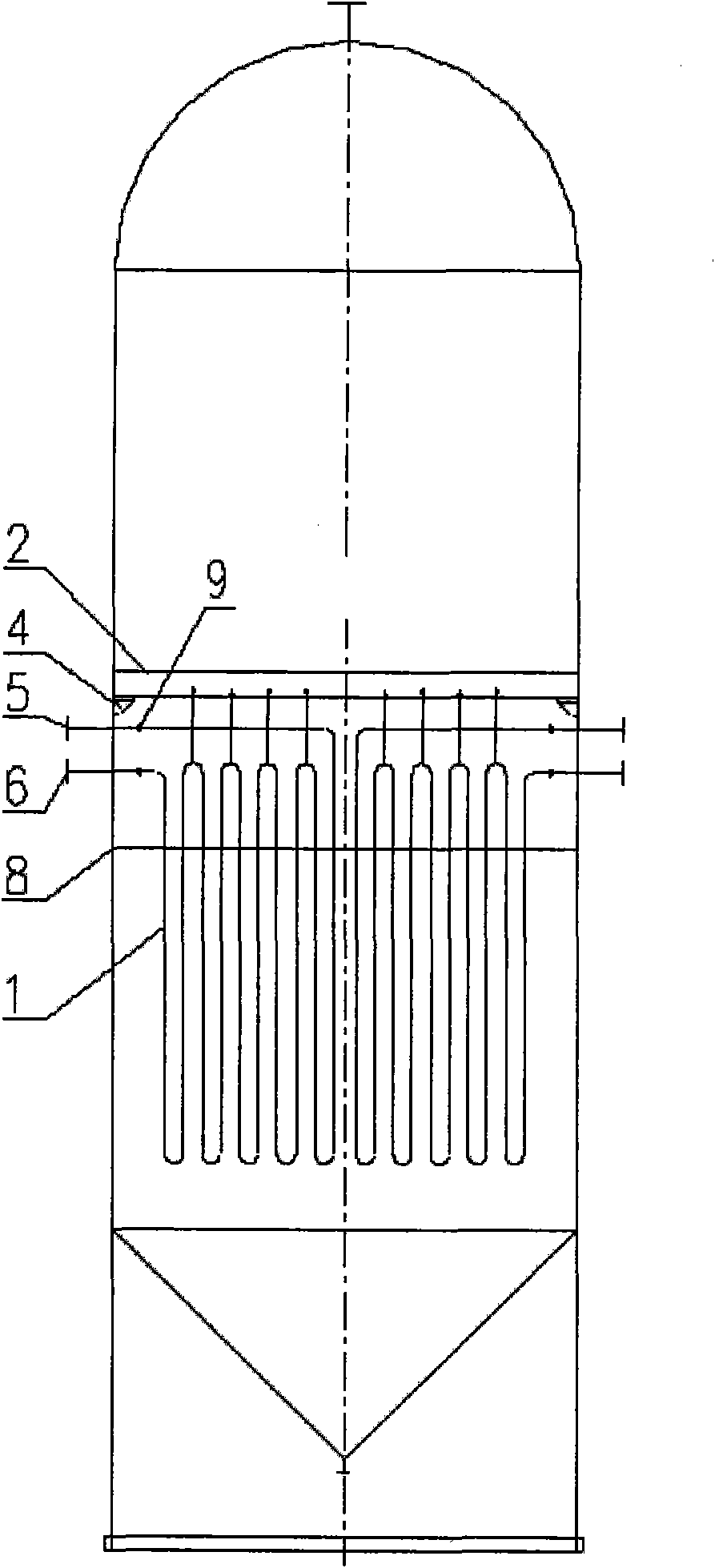

[0033]The acrylonitrile or methacrylonitrile production plant with an annual output of 70,000 tons will increase its production capacity to 80,000 tons per year with the original reactor shell and the position of the original cooling water pipe inlet and outlet unchanged. During the renovation process, the diameter of the reactor shell remained unchanged at 7470 mm, and the height of...

Embodiment 2

[0035] The proportioning, reaction conditions, and reaction process of the raw material gas for producing acrylonitrile or methacrylonitrile are the same as [Example 1].

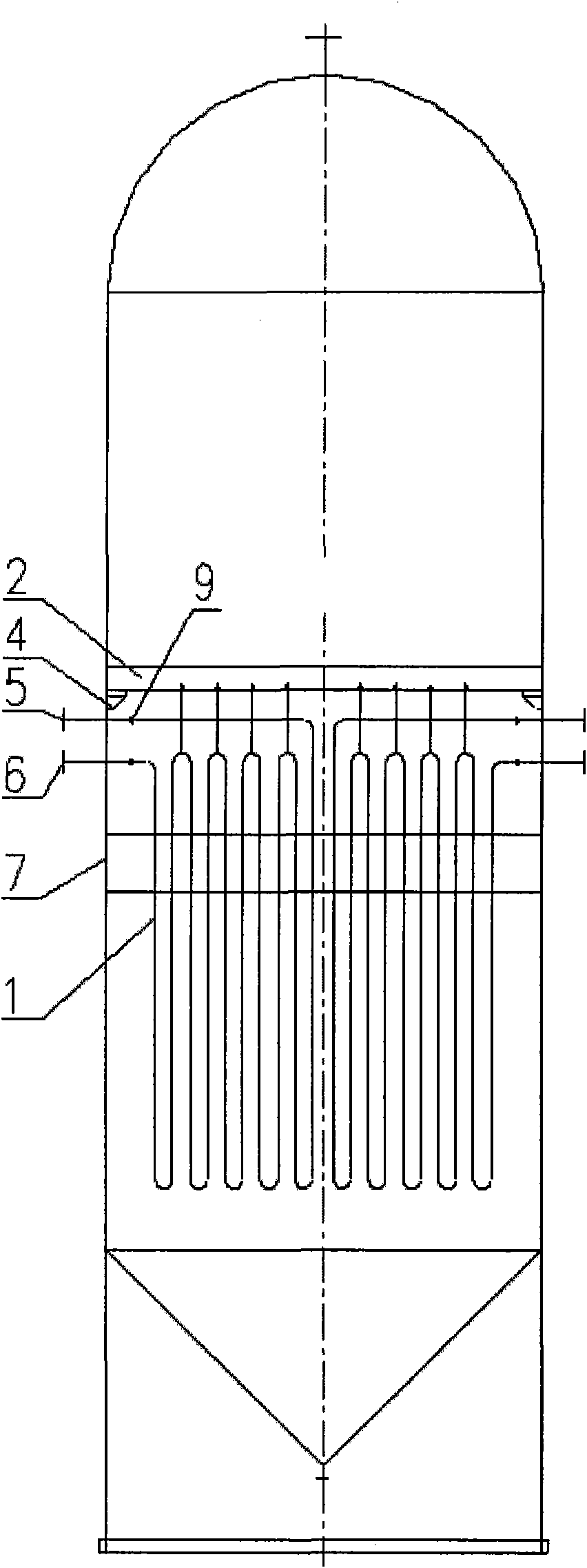

[0036] The acrylonitrile or methacrylonitrile production plant with an annual output of 70,000 tons will be increased to an annual output of 92,000 tons while the original reactor shell and the position of the inlet and outlet of the original cooling water pipe remain unchanged. The diameter of the reactor shell remains unchanged at 7470mm, and the height of the shell remains unchanged at 17500mm. In order to increase the output, the support beam 2 is increased by 1 meter, and the height of the cooling water pipe is also increased by 1 meter. The straight pipe section is increased from the original 5790mm To 6790mm, in order to withdraw the heat generated by increasing the reaction raw materials. The inlet and outlet flanges 5 and 6 of the cooling water pipes and the support beam 2 are old, and the cooling w...

Embodiment 3

[0038] The proportioning, reaction conditions, and reaction process of the raw material gas for producing acrylonitrile or methacrylonitrile are the same as [Example 1].

[0039] The original production capacity of acrylonitrile or methacrylonitrile with an annual output of 70,000 tons will be increased to 105,000 tons per year while the original reactor shell and the position of the inlet and outlet of the original cooling water pipe remain unchanged. The diameter of the reactor shell remains unchanged at 7470mm, and the height of the shell remains unchanged at 17500mm. In order to increase the output, the support beam 2 is increased by 1.5 meters, and the height of the cooling water pipe is also increased by 1.5 meters. The straight pipe section is increased from the original 5790mm To 7200mm, in order to withdraw the heat generated by increasing the reaction raw materials. The inlet and outlet flanges 5 and 6 of the cooling water pipes and the support beam 2 are old, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com