Lining for cloth, trousers and coat with the lining for cloth

A lining and clothing technology, applied in the field of lining for clothing and pants and tops using the lining for clothing, can solve the problems of bleaching, fading, etc., and achieve bleaching fastness, rub resistance, strong color tone. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

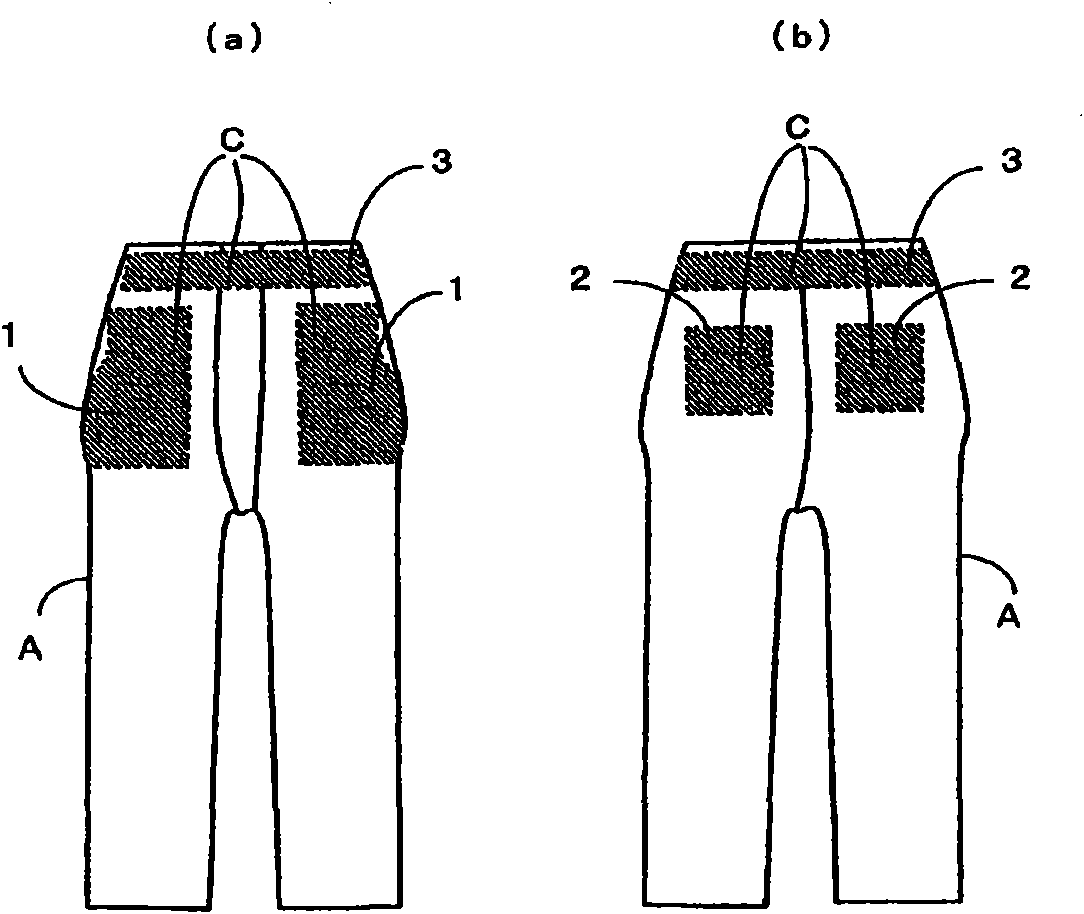

[0072] Below, based on figure 1 and figure 2 , an embodiment of the liner to which the present invention is applied will be described. The clothes shown above are trousers A and jacket B worn mainly as casual clothes.

[0073] An example of trousers A to which the liner of the present invention is applied will be described. Such as figure 1 As shown, the trousers A is trousers, and the gray fabric 1 for the left and right side pockets, the gray fabric 2 for the left and right waist pockets, and the gray fabric 3 for waistband lining around the waistband use the lining of the present invention.

[0074] The trousers A are trousers, but are not limited to trousers, and may be cropped trousers or shorts.

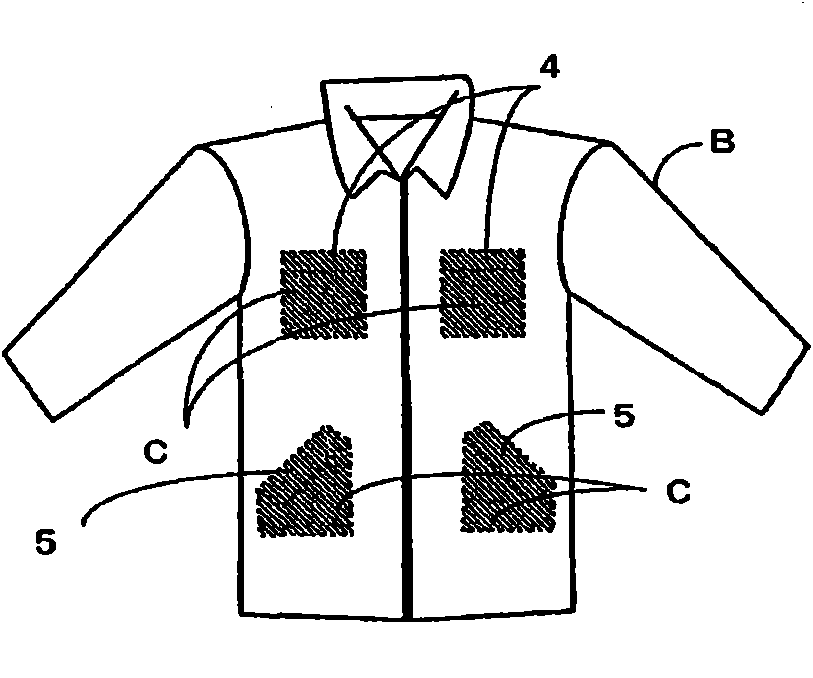

[0075] Next, based on figure 2 , the structure of the jacket B to which the lining of the present invention is applied will be described. Such as figure 2 As shown, the jacket B is a long-sleeved jacket, and the lining of the present invention is used on a pair of lef...

Embodiment 1

[0131] A 1.7 dtex x 38 mm spun-dyed polyester staple fiber containing 2.0 mass % of carbon black as a colorant based on the total amount of the spun-dyed polyester fiber was prepared. Similarly, 2% by mass of carbon black as a coloring agent is added to the spun-dyed rayon relative to the total amount of the spun-dyed rayon, and the 1.7dtex×38mm spun-dyed rayon is produced by the viscose rayon process short fibre. Next, the staple fibers containing 65% of the spun-dyed polyester staple fibers and 35% of the spun-dyed rayon staple fibers are subjected to cotton blending, carding, and cooked sliver through the ring spinning process of the usual method. , slubbing, worsted spinning process, obtain the black staple fiber yarn of Ne30.

[0132] Use this yarn to weave a 2 / 1 left direction twill fabric with 83 threads / 2.54cm, 63 threads / 2.54cm, and CF=26.7, and then go through conventional singeing, desizing, refining processes, and post-drying treatment process A heat-setting trea...

Embodiment 2

[0135] Except making short fibers containing 50% spun-dyed polyester staple fibers and 50% spun-dyed rayon staple fibers, all the other were the same as in Example 1 to obtain Ne30 black staple fiber yarns.

[0136] The yarn thus obtained is used for warp. On the other hand, as a weft yarn, 167dtex / 36f dope-dyed polyester filaments containing 2.0% by mass of carbon black as a colorant were used to weave 2 yarns of 83 yarns / 2.54cm, 65 yarns / 2.54cm, and CF=28. / 1 left direction twill fabric, then go through the conventional singeing, desizing, refining process, and apply heat setting treatment (170 ° C × 45 seconds) through the post-drying treatment process to stabilize the shrinkage of the gray cloth, and obtain a 71% Black twill made of polyester, 29% rayon.

[0137] The same evaluation and judgment as in Example 1 were performed on the obtained twill fabric. Table 1 shows the test results.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com