PHC pile-based multiple high jet pedestal pile construction method

A technology of PHC pile and construction method, which is applied in basic structure engineering, sheet pile wall, building and other directions, can solve the problems of limited strength, limited application and damage, and achieve the effect of improving strength and obvious economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

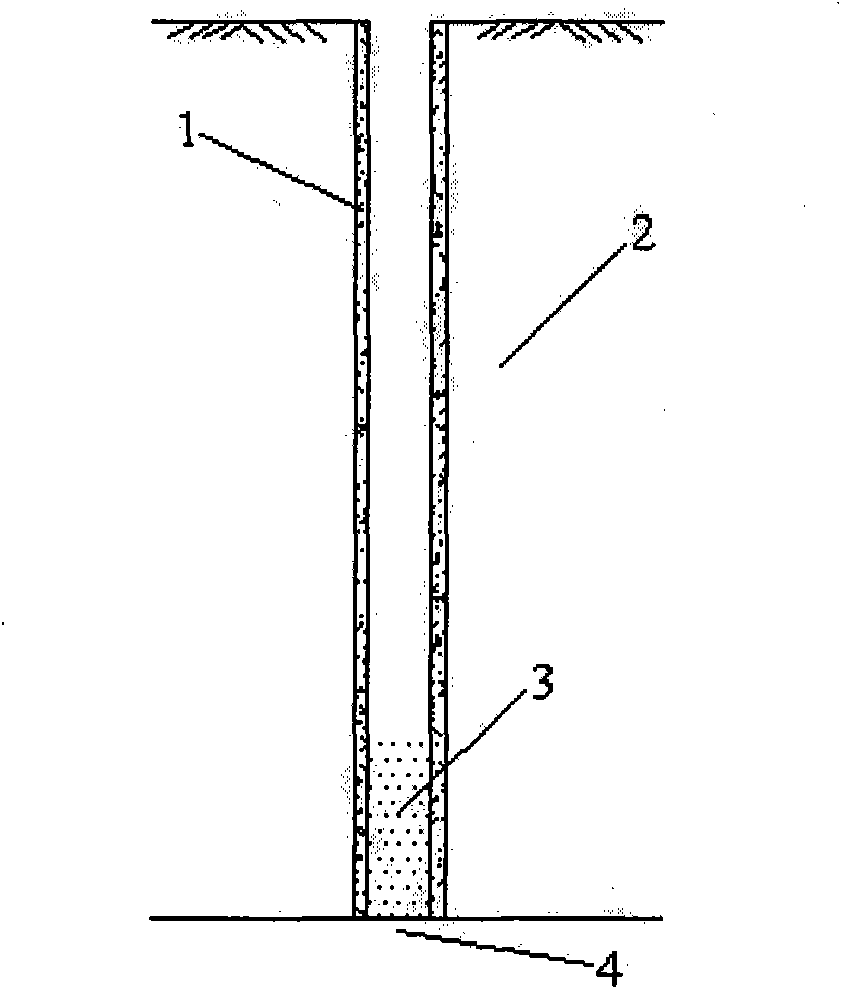

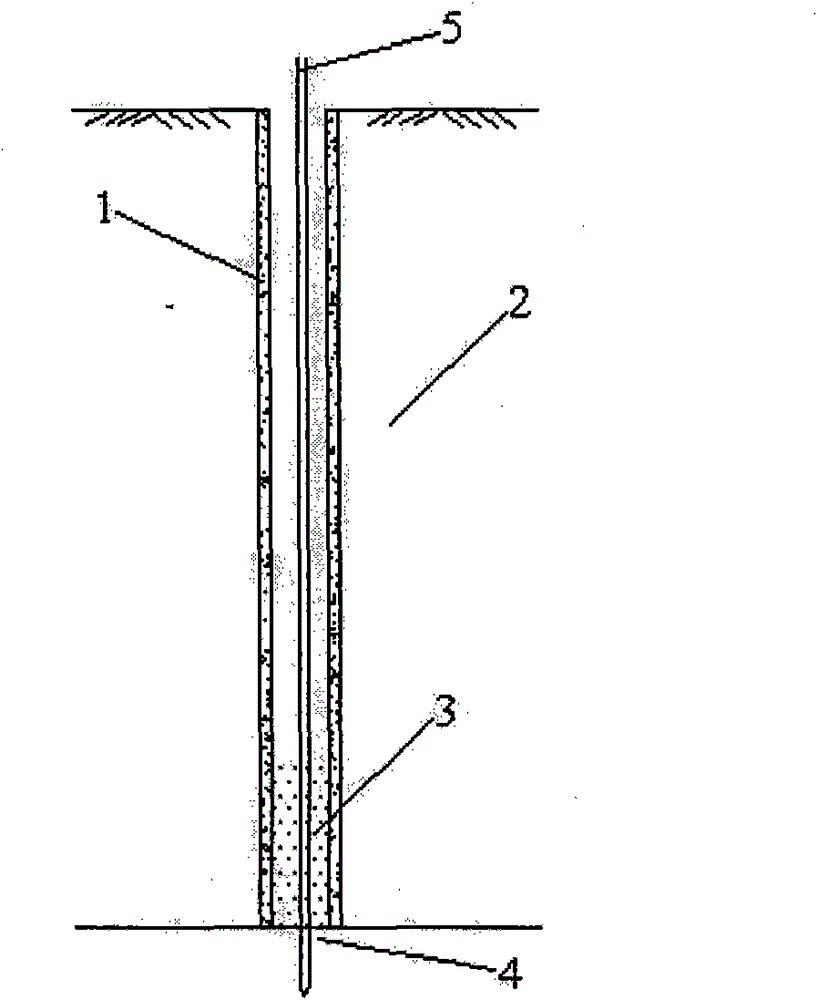

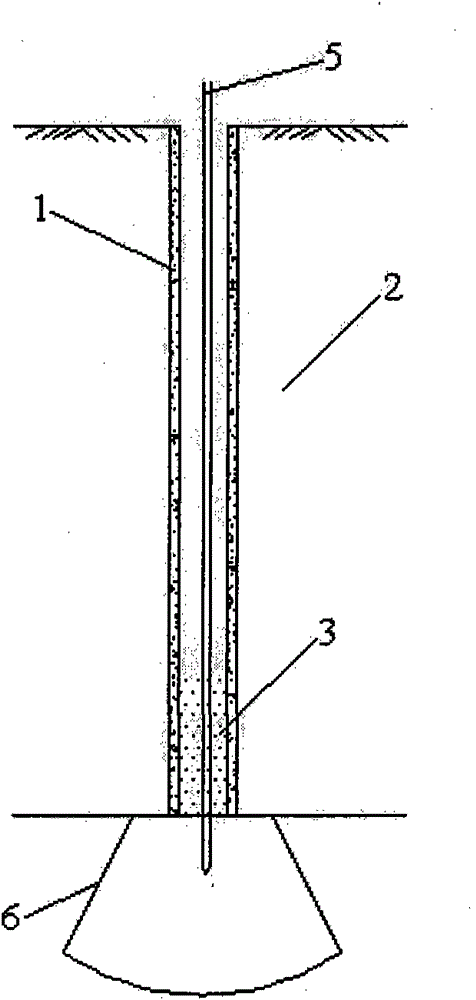

[0038] like Figure 1 to Figure 6 As shown, a construction method of multiple high sprayed bottom piles based on PHC piles, the main technical steps are as follows:

[0039] (1) Static pressure PHC pile 1 to the design depth. The construction technology of PHC pile 1 is relatively mature, especially with the new type of static pile pressing machine put into use, the static pressure construction method without noise, vibration and oil fume, etc., has developed rapidly.

[0040] (2) The multiple high-pressure jet-jet drill pipes 5 are drilled to the soil layer at the bottom of the PHC pile 1 . After the PHC pile 1 is constructed, the multiple high-pressure rotary jet drilling rigs are in place, and the multiple drill pipes 5 are drilled through the hollow part of the PHC pile 1 to the soil layer at the bottom of the PHC pile.

[0041] (3) Enlarging the construction of the head cavity 6 . The multiple drill pipes 5 reciprocate impact and suction up and down in the soil layer a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com