Magnetic textile

A textile and magnetic technology, used in textiles, papermaking, pharmaceutical formulations, etc., can solve problems such as uneven distribution, poor magnetic powder dispersion, and energy resonance cloth cannot reach medical grades, and achieve uniform distribution, high magnetic density, and soft hand feel. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

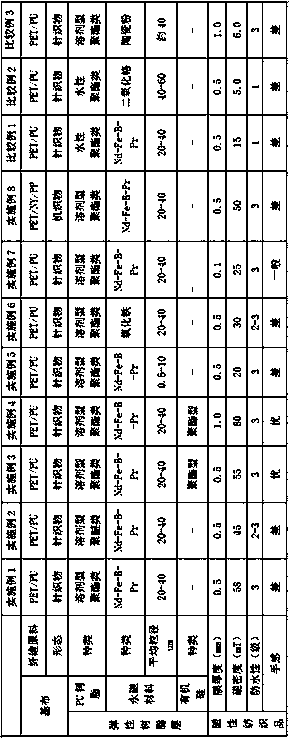

Embodiment 1

[0051] (1) Prepare base fabric: PET / PU knitted fabric

[0052] (2) Configure magnetic coating resin processing fluid:

[0053] 30 parts by weight of solvent-based polyester PU resin

[0054] Permanent magnet material (Nd-Fe-B-Pr, 90% particle size less than 40um) 70 parts by weight

[0055] 20 parts by weight of toluene

[0056] Use a vacuum mixer to mix the components evenly, and obtain a magnetic coating resin after degassing by a vacuum degassing machine;

[0057] (3) On the coating machine, apply the above-mentioned magnetic coating resin processing fluid on the prepared base fabric by scraping; minutes; the second heating temperature is 130°C, and the curing time is 1.5 minutes;

[0058] (4) cooling to obtain the magnetic textile of the present invention. The performance parameters of the obtained textiles are shown in Table 1.

Embodiment 2

[0060] The solvent-based polyester PU resin was replaced by the solvent-based polyether PU resin, and the rest was the same as in Example 1 to obtain the magnetic textile of the present invention. The performance parameters of the obtained textiles are shown in Table 1.

Embodiment 3

[0062] The composition of magnetic coating resin processing fluid is as follows:

[0063] 20 parts by weight of polyester type PU resin

[0064] Permanent magnet material (Nd-Fe-B-Pr) 70 parts by weight

[0065] Softener (polyester modified silicone) 10 parts by weight

[0066] 20 parts by weight of toluene

[0067] Two heating and curing processes, the first heating temperature is 110°C, the curing time is 1 minute; the second heating temperature is 150°C, the curing time is 1 minute heating and curing, and the rest is the same as in Example 1 to obtain the magnetic textile of the present invention. The performance parameters of the obtained textiles are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com