Composite flexible uniform pressure loading device suitable for geomechanical model test

A model test and geomechanics technology, applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, scientific instruments, etc., can solve the problems of difficult perforation wiring, large load deviation, stress concentration, etc., and achieve good loading effect. , easy operation, reasonable size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

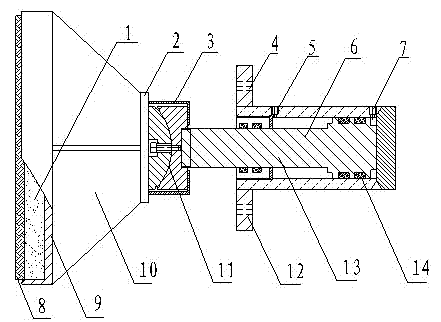

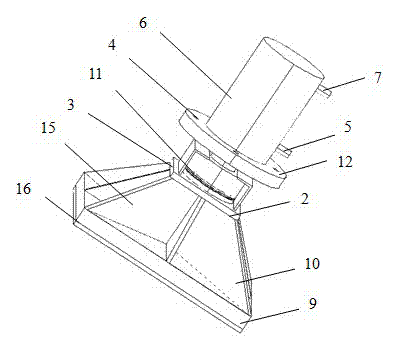

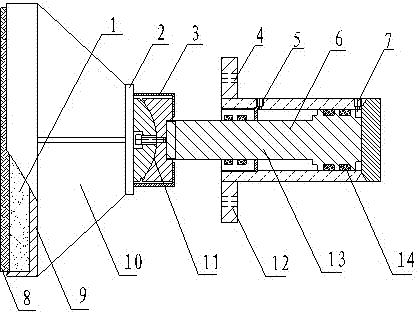

[0033] Such as figure 1 , figure 2 As shown, the present invention is a composite flexible uniformly distributed pressure loading device suitable for geomechanical model tests, including a hydraulic cylinder 6, a ball joint 11, a hydraulic cylinder thruster 15 and a composite flexible force transmission cushion 16, and the hydraulic cylinder The upper end of the thruster 15 is connected to the hydraulic cylinder 6 through a ball joint 11, and a layer of composite flexible force transmission pad 16 is provided at the bottom.

[0034] The hydraulic cylinder thruster 15 includes an upper plate 2 and a lower plate 9, the lower plate 9 is grooved, and the upper and lower plates are connected by a number of evenly distributed stiffeners 10, which are trapezoidal; the upper part of the upper plate 2 is provided with The ball hinge slot 3, the hydraulic cyli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com