Method and device for protecting silicon wafer edge

A silicon wafer edge protection and edge protection technology, applied in the field of integrated circuit manufacturing, can solve problems such as low efficiency, and achieve the effects of reducing processes, easy online implementation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

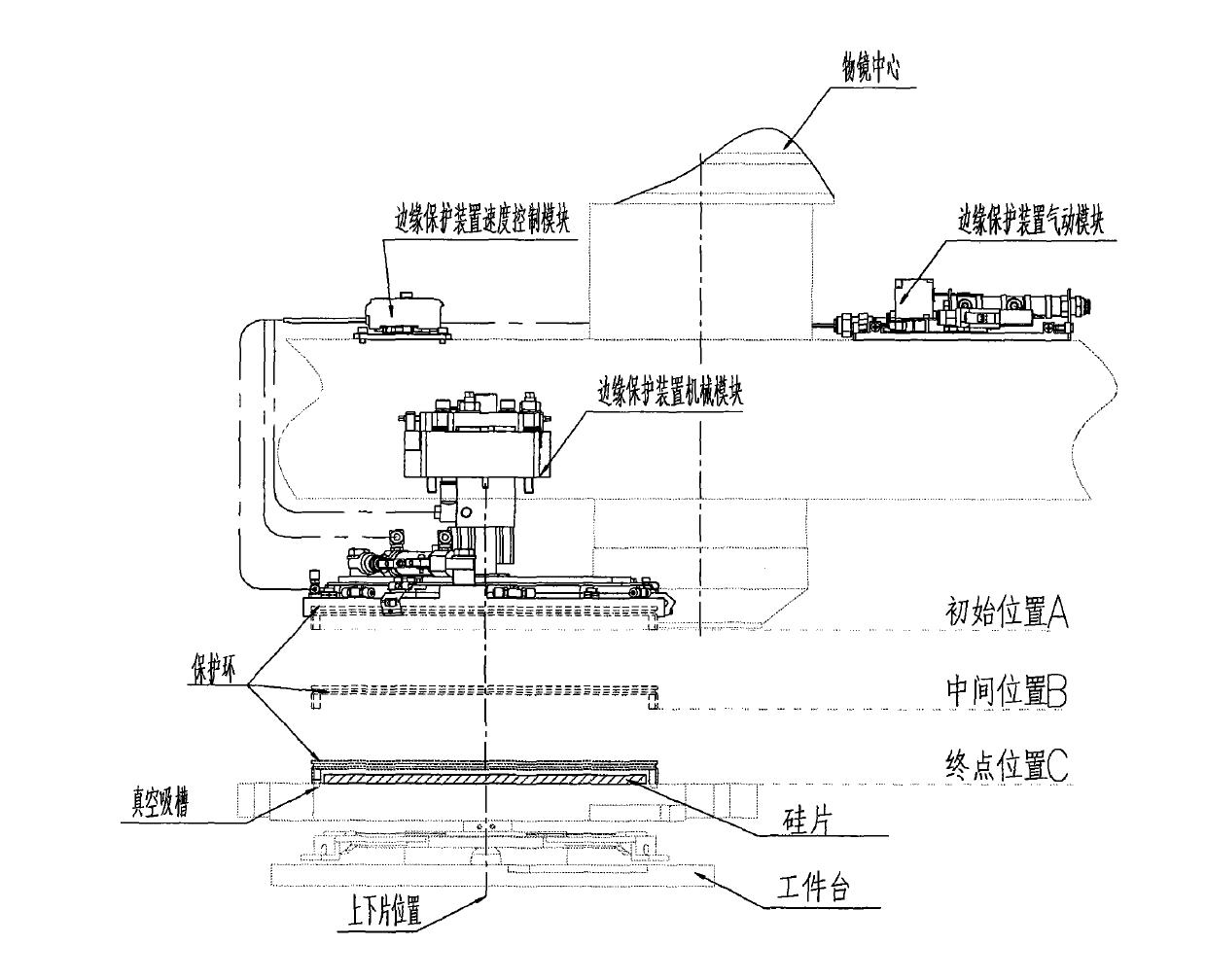

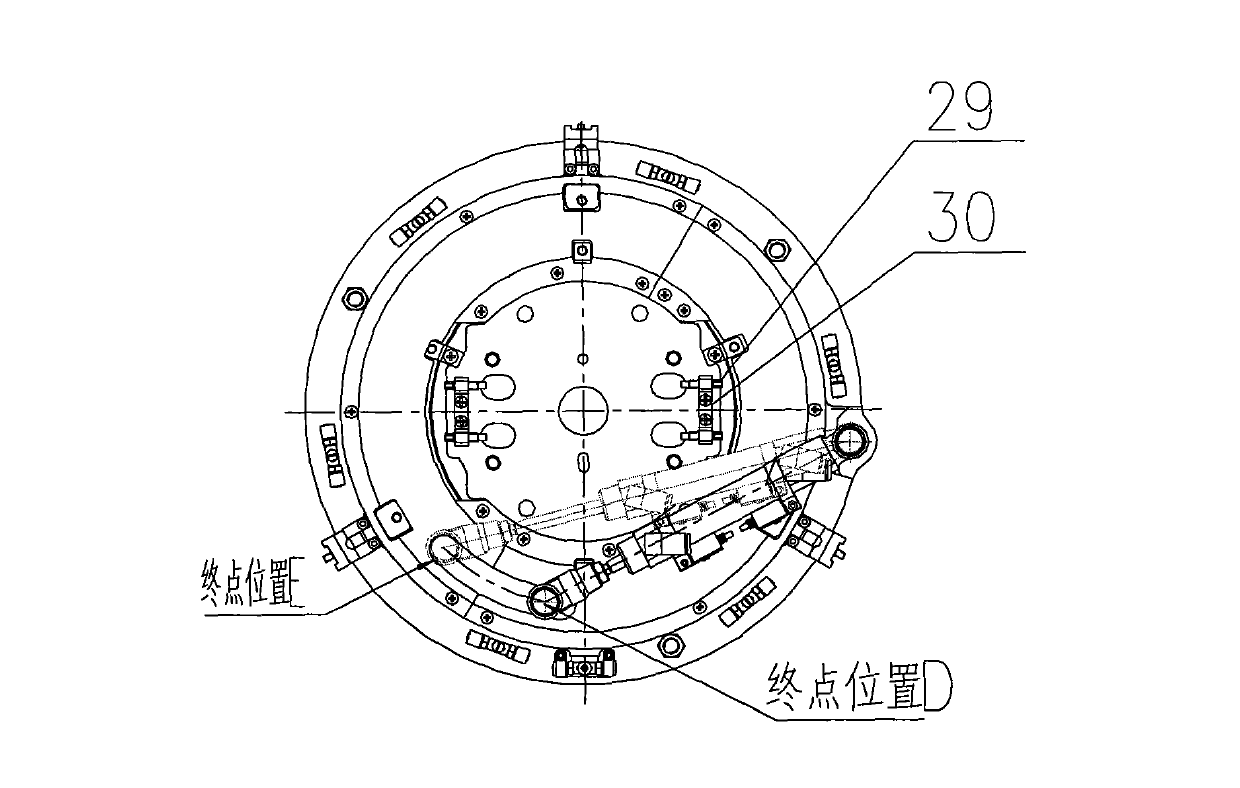

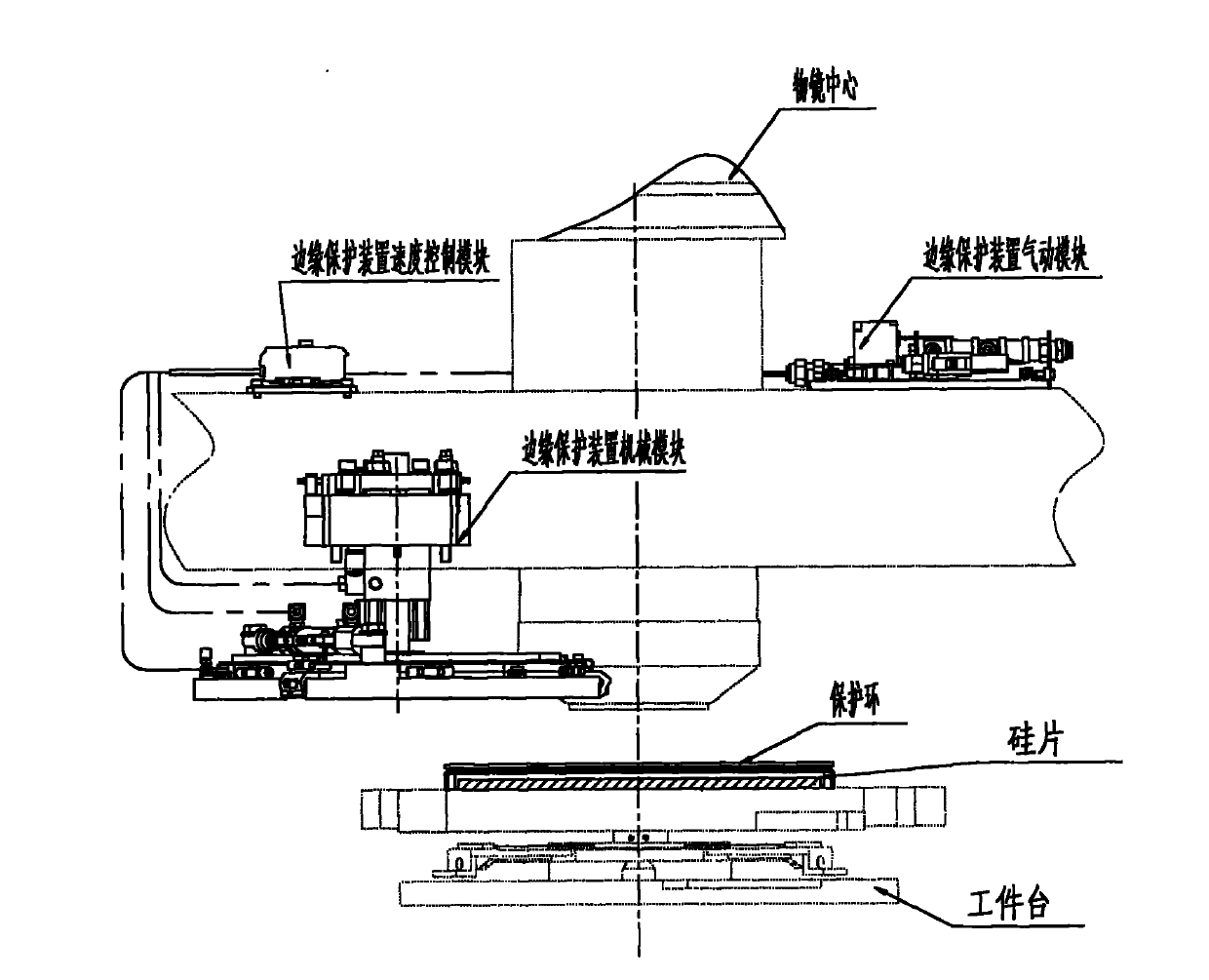

[0050] In order to better understand the technical content of the present invention, specific embodiments are given together with the attached drawings for description as follows.

[0051] The invention provides a method and device for protecting the edge of a silicon chip, which protects the edge of the silicon chip when it is exposed, and does not need to go through two processes to process the edge of the silicon chip, thereby reducing the number of processes and improving production efficiency.

[0052] The present invention determines the method that negative glue exposure and edge protection carry out synchronously, realizes silicon chip edge protection with a kind of mechanical method, to realizing negative glue process exposure process silicon chip edge protection function, comprises the following steps:

[0053] Use the silicon wafer edge protection device to place the protective ring on the workpiece table where the silicon wafer is placed before the objective lens is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com