Water-reactive Al composite material, water-reactive Al film, method for production of the Al film, and structural member for film-forming chamber

A composite material and manufacturing method technology, applied in chemical instruments and methods, metal material coating process, semiconductor/solid-state device manufacturing, etc., to achieve the effect of increasing the number of reuses and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

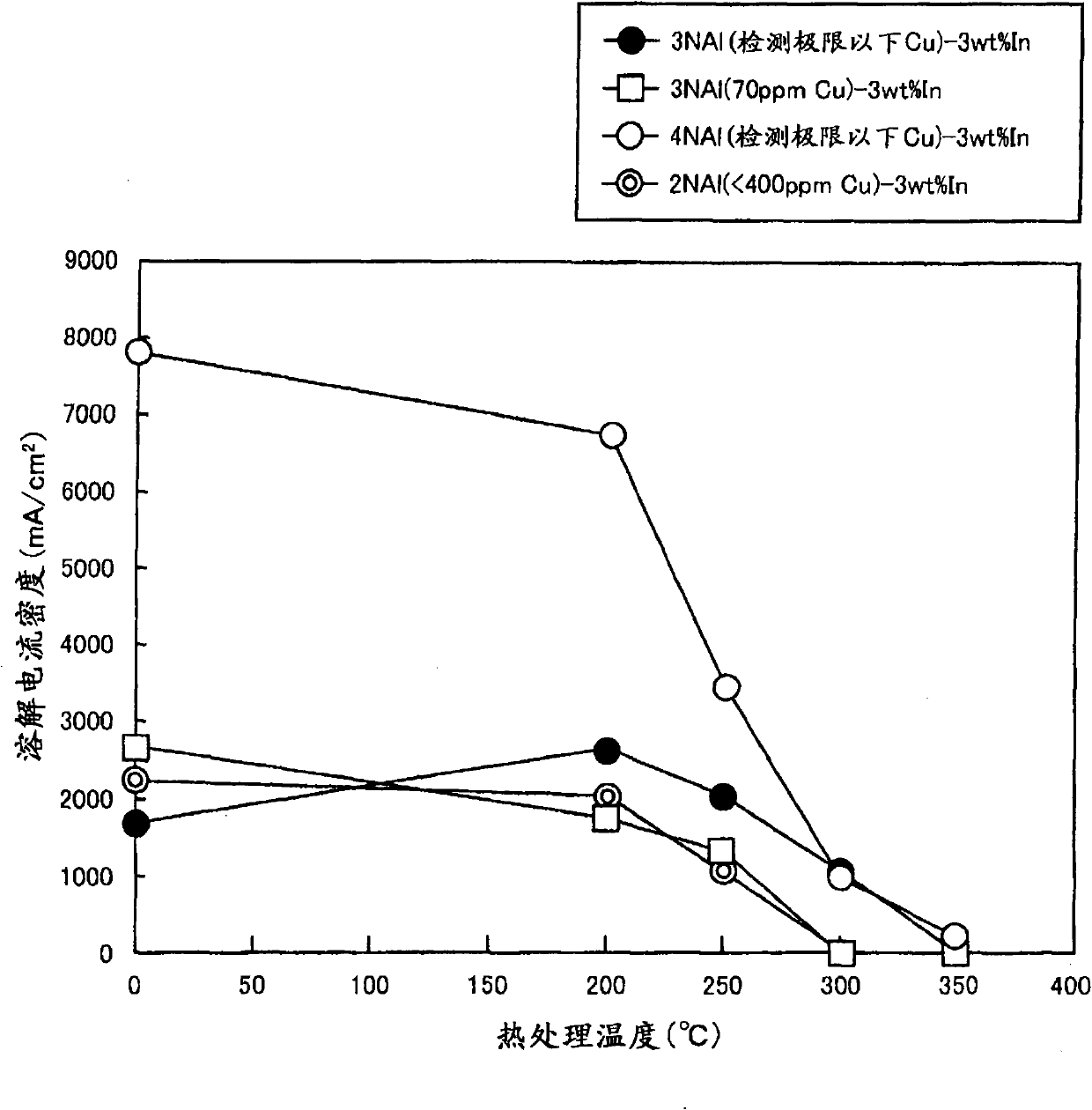

[0059] 2NAl, 3NAl, and 4NAl were used, and the relationship between the purity of Al in the Al-In composition to which In was added, the amount of impurity Cu in Al, and the solubility of the thermally sprayed film obtained was studied. The amount of In added is based on the weight of Al.

[0060] 2NAl (impurity Cu: <400ppm)-3wt%In

[0061] 3NAl (impurity Cu: 70ppm)-3wt%In

[0062] 3NAl (impurity Cu: below the detection limit)-3wt%In

[0063] 4NAl (impurity Cu: below the detection limit)-3wt%In

[0064] Using a thermal spraying material that mixes Al and In in the above proportions, dissolves In uniformly in Al, and processes it into a rod shape, it is sprayed by molten rod flame (heat source: C 2 h 2 -O 2 gas, about 3000°C), in the air atmosphere, spray on the surface of the aluminum substrate to form a sprayed coating. For each of the thermally sprayed coatings obtained in this way, instead of the heat history received by the film formation process, heat treatment at roo...

Embodiment 2

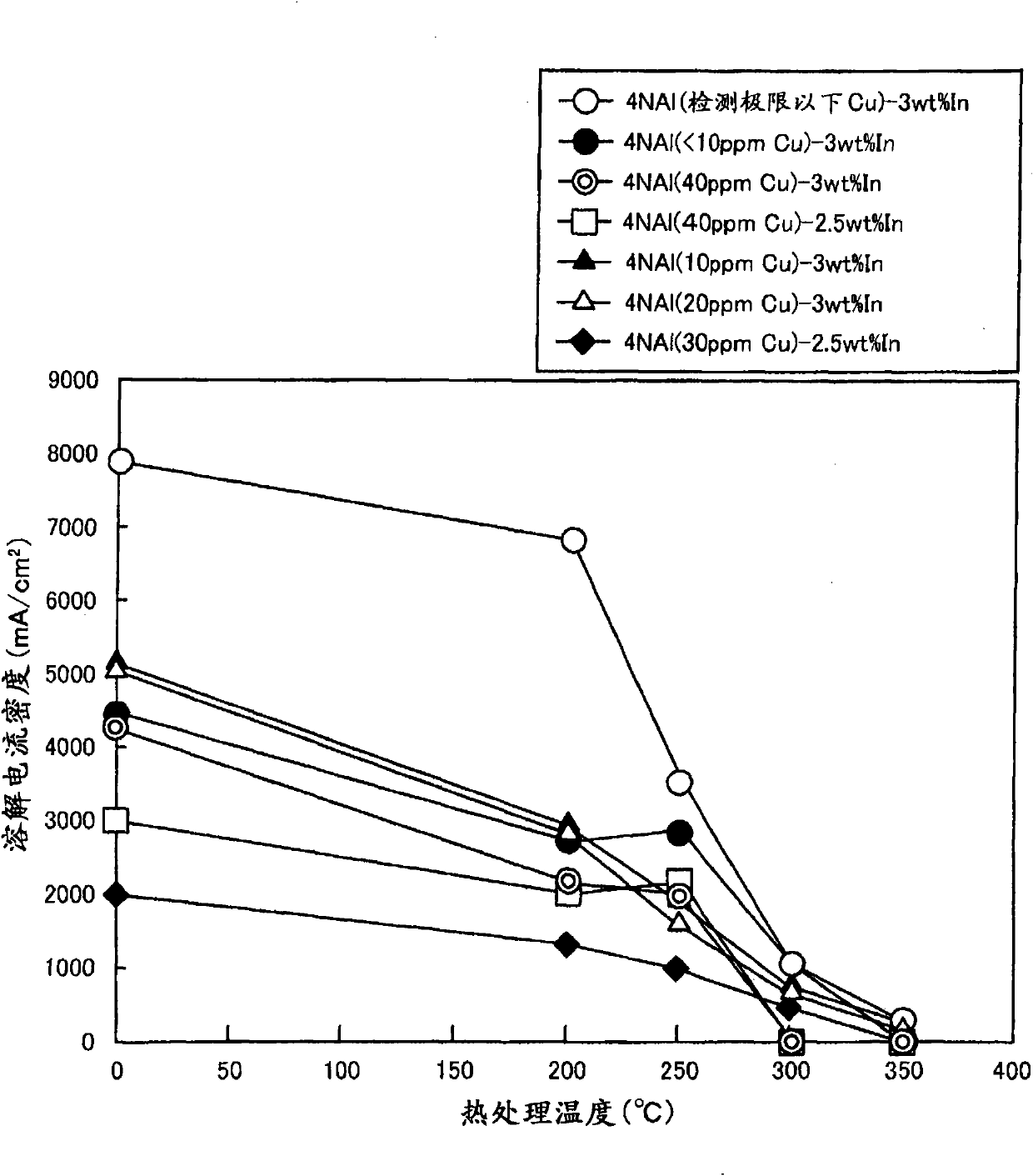

[0068] In this example, the relationship between the amount of Cu impurity in the Al-In composition using 4NAl and In added thereto, and the solubility of the thermally sprayed film obtained was investigated. The amount of In added is based on the weight of Al.

[0069] 4NAl (impurity Cu: below the detection limit)-3wt%In

[0070] 4NAl (impurity Cu: <10ppm)-3wt%In

[0071] 4NAl (impurity Cu: 40ppm)-2.5wt%In

[0072] 4NAl (impurity Cu: 40ppm)-3wt%In

[0073] 4NAl (impurity Cu: 10ppm)-3wt%In

[0074] 4NAl (impurity Cu: 20ppm)-3wt%In

[0075] 4NAl (impurity Cu: 30ppm)-2.5wt%In

[0076] Using a thermal spraying material that mixes Al and In in the above proportions, dissolves In uniformly in Al, and processes it into a rod shape, it is sprayed by molten rod flame (heat source: C 2 h 2 -O 2 gas, about 3000°C), in the air atmosphere, spray on the surface of the aluminum substrate to form a sprayed coating. For each of the thermally sprayed coatings obtained in this way, ins...

Embodiment 3

[0080] In an Al-In-Si composition using 4NAl and adding In and Si (total amount of Si as an impurity), the relationship between the purity of Al, the amount of Si added, and the solubility of the resulting thermally sprayed coating was investigated. The addition amounts of In and Si are based on Al weight.

[0081] 4NAl (impurity Cu: 10ppm or less)-2wt%In-0.05wt%Si

[0082] 4NAl (impurity Cu: 10ppm or less)-3wt%In-0.1wt%Si

[0083] 4NAl (impurity Cu: 10ppm or less)-4wt%In-0.5wt%Si

[0084] 5NAl (impurity Cu: 10ppm or less)-1.5wt%In-0.05wt%Si

[0085] ・5NAl (impurity Cu: 10ppm or less)-2.6wt%In-0.1wt%Si

[0086] ・5NAl (impurity Cu: 10ppm or less)-3.5wt%In-0.5wt%Si

[0087] Al, In, and Si were blended in the above-mentioned ratio (the amount of Si blended is represented by the amount of Si containing impurities), and a sprayed coating was formed in the same manner as in Example 1. About each sprayed coating obtained in this way, it heat-processed similarly to Example 1 (in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com