Multifuel internal-combustion engine

An internal combustion engine, multi-fuel technology, applied in liquid fuel feeders, internal combustion piston engines, combustion engines, etc., can solve the problems of increased PM and soot generation, and achieve noise suppression, torque fluctuation suppression, NOx suppression The effect of increasing the amount of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

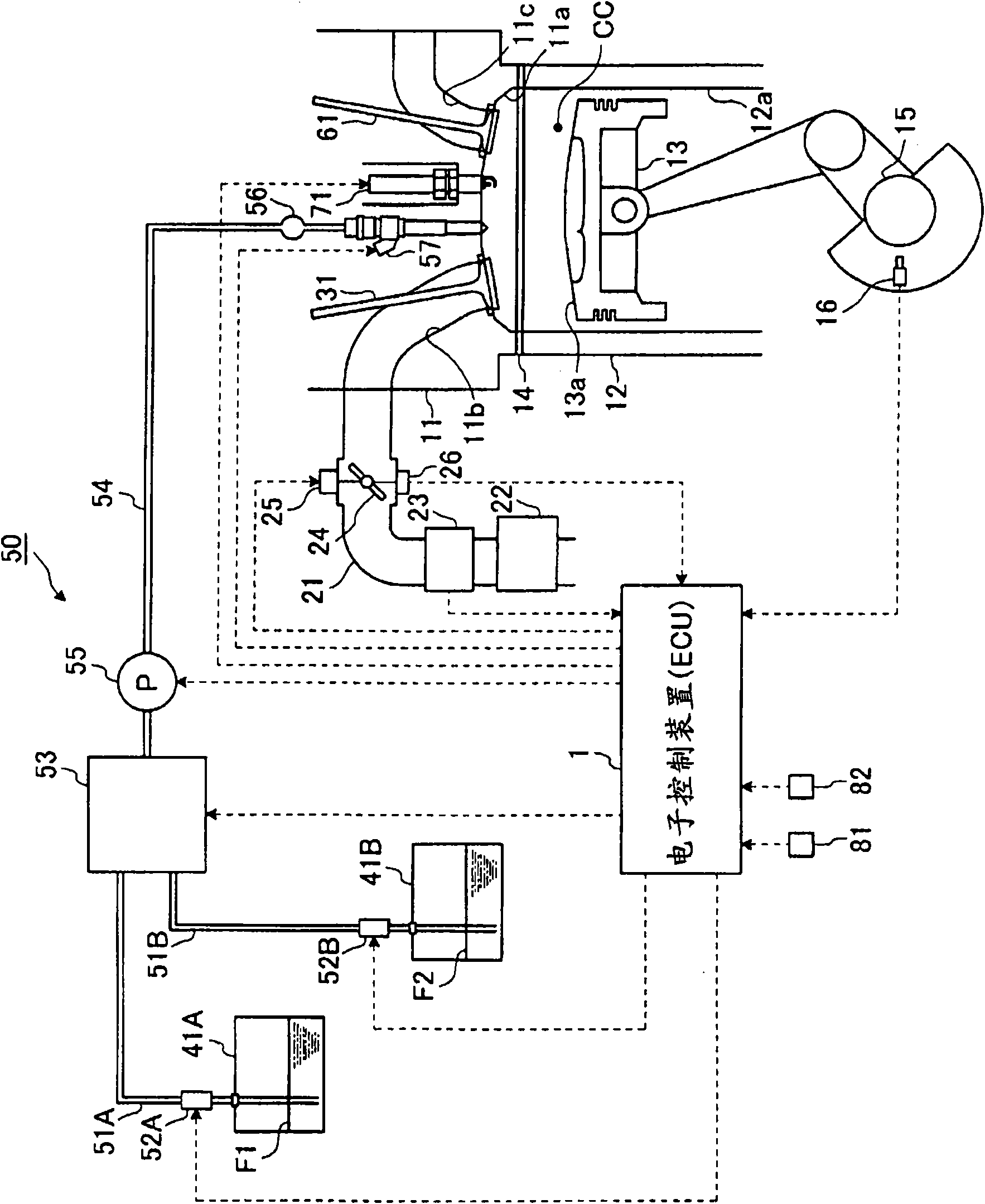

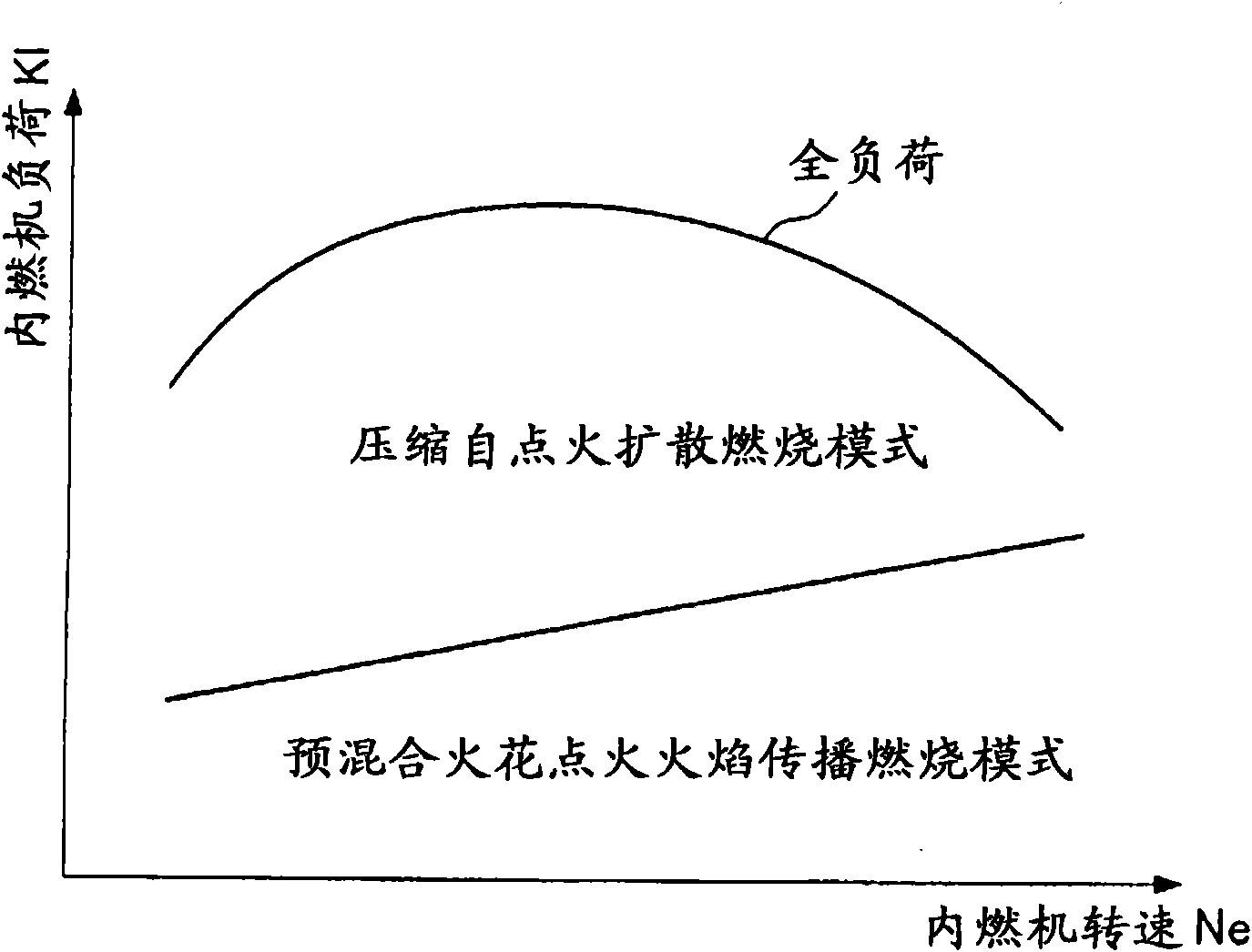

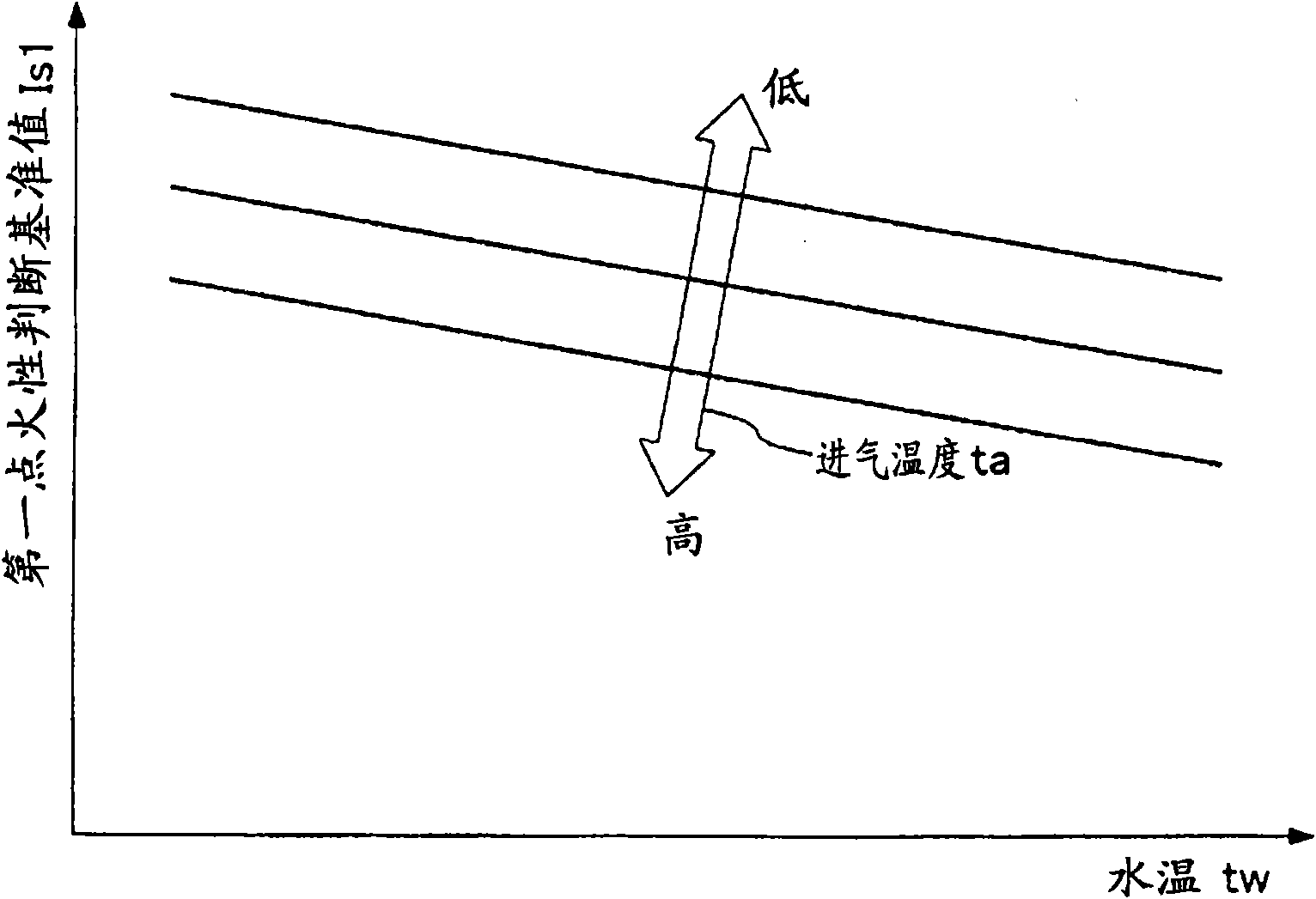

[0066] Below, according to Figure 1 to Figure 7 Embodiment 1 of the multi-fuel internal combustion engine according to the present invention will be described. The multi-fuel internal combustion engine is an internal combustion engine that operates by introducing at least one fuel of at least two fuels having different properties into a combustion chamber, or introducing a mixed fuel composed of the at least two fuels into the combustion chamber. In this embodiment, the latter multi-fuel internal combustion engine is taken as an example for description.

[0067] This multi-fuel internal combustion engine, with figure 1 The illustrated electronic control unit (ECU) 1 performs various control operations such as combustion control. This electronic control device 1 is composed of a CPU (Central Processing Unit) not shown in the figure, a ROM (ReadOnly Memory) in which predetermined control programs, etc. are stored in advance, and a RAM (Random Access Memory: random access mem...

Embodiment 2

[0137] Second, according to Figure 8 and Figure 9 Embodiment 2 of the multi-fuel internal combustion engine according to the present invention will be described.

[0138] Generally, if the in-cylinder pressure in the combustion chamber CC can be detected, the ignition timing of the pre-injected fuel or the increase rate of the in-cylinder pressure can be grasped from the change in the pressure. Thus, in the multi-fuel internal combustion engine of Embodiment 1 described above, in a case where the in-cylinder pressure can be detected or estimated, it can be judged whether or not the pre-injected fuel is undergoing rapid combustion. In addition, the larger the pre-injection amount FP, the higher the cylinder pressure, and the increase rate of the cylinder pressure due to the pre-injection can be reversed to calculate the pre-injection amount FP. Therefore, by feeding back the increase rate of the in-cylinder pressure at the time of the next pre-injection, even if the Figur...

Embodiment 3

[0159] Second, based on Figure 10 Embodiment 3 of the multi-fuel internal combustion engine according to the present invention will be described.

[0160] In each of the above-mentioned Embodiments 1 and 2, an example of a so-called direct-injection multi-fuel internal combustion engine in which the mixed fuel of the first fuel F1 and the second fuel F2 is directly injected into the combustion chamber CC was exemplified. However, this Embodiment 3 exemplifies a multi-fuel internal combustion engine in which this mixed fuel is injected not only into the combustion chamber CC but also into the intake port 11b.

[0161] For example, this kind of multi-fuel internal combustion engine can be replaced by the fuel supply device 50 in the multi-fuel internal combustion engine of each embodiment 1, 2 Figure 10 The fuel supply device 150 shown is constructed. In addition, the Figure 10 The case based on the multi-fuel internal combustion engine of the first embodiment is exemplifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com