Naturally flavor-enhancing liquid dairy product and preparation method thereof

A dairy product and liquid technology, which is applied in the field of natural aroma-enhancing liquid dairy products and its preparation, can solve problems such as bad taste and flavor, decrease in stability, and aggravate the flavor of finished products, so as to enrich the market, improve quality, and meet the needs of taste Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

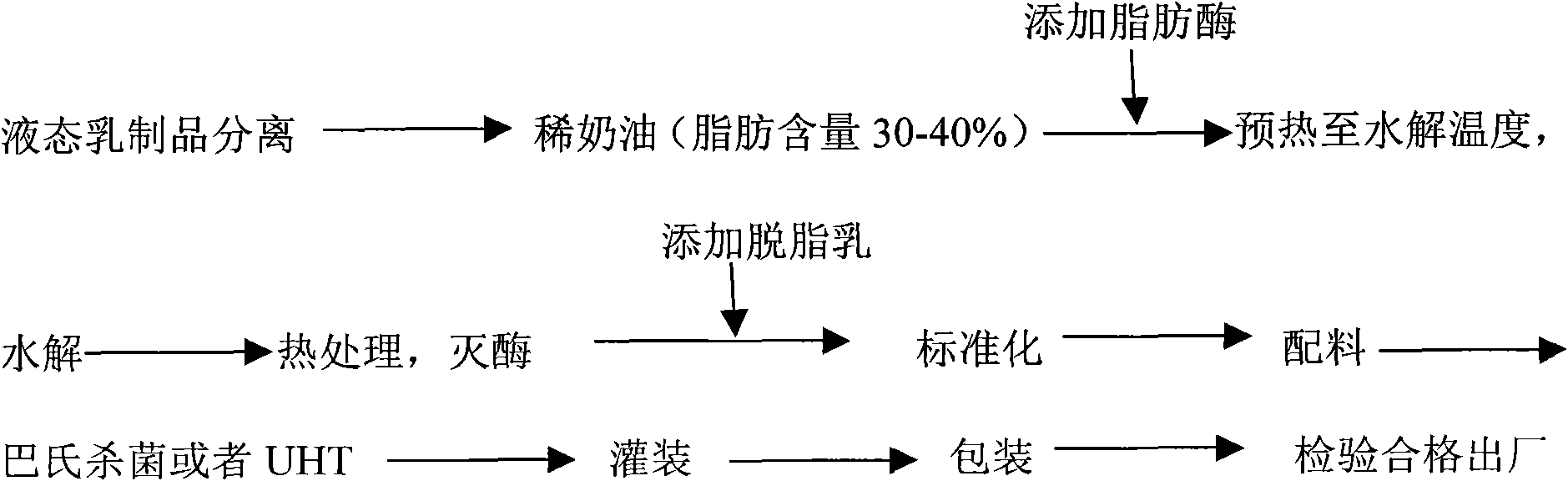

Method used

Image

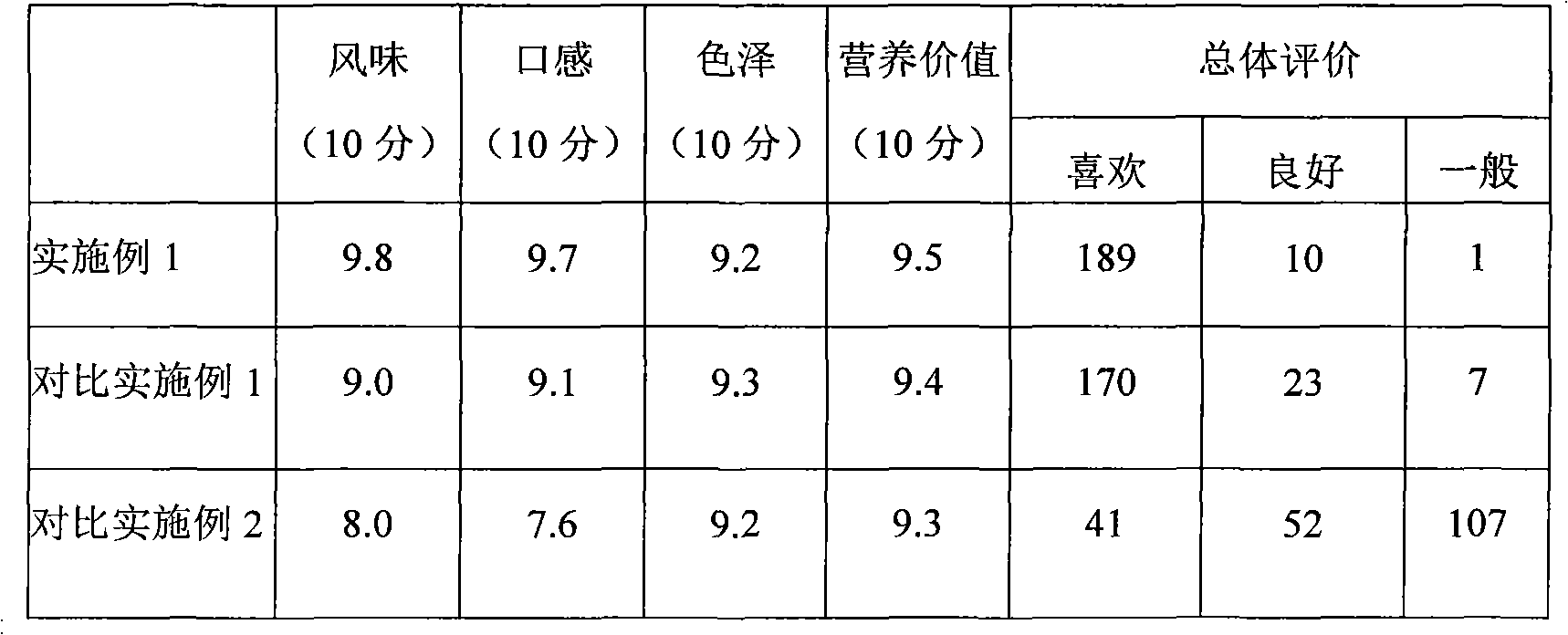

Examples

Embodiment 1

[0032] Formula: 998.5 parts of milk, 0.5 part of lipase (enzyme activity is 2400FCCLU / g), 1 part of monoglyceride.

[0033] The preparation method of the present invention comprises the following steps in turn:

[0034] (1) Raw milk whose temperature does not exceed 8°C is heated to 35°C for separation, and the fat content of the cream is 35%;

[0035] (2) adding lipase to the cream at 35°C for 8 hours of hydrolysis, heating up to 80°C, and heat-treating for 20 minutes;

[0036] (3) According to the index requirements of the prepared milk, add skim milk, stir and mix evenly, and then cool to 8°C;

[0037] (4) Prepare the milk composition and perform homogenization: heat the milk composition to 65° C., add monoglyceride, stir for 15 minutes, and perform homogenization. The homogenization pressure is 200 bar (first adjust the secondary pressure to 40 bar, and then raise 200bar), add the remaining standardized milk;

[0038] (5) Sterilize the prepared milk composition at 121° ...

Embodiment 2

[0040] Formula: 600 parts of milk, 1 part of lipase (enzyme activity is 2400FCCLU / g), 2 parts of sucrose ester, 1 part of milk mineral salt, and 396 parts of water.

[0041] The preparation method of the present invention comprises the following steps in turn:

[0042] (1) Raw milk whose temperature does not exceed 8°C is heated to 45°C for separation, and the fat content of the cream is 30%;

[0043] (2) adding lipase to the cream for hydrolysis for 6 hours, heating up to 80° C., and heat-treating for 20 minutes;

[0044] (3) According to the requirements of the index, add skim milk, stir and mix well, and then cool to 8°C;

[0045] (4) Prepare the milk composition and perform homogenization: heat the milk composition to 65° C., add sucrose ester and milk mineral salt, stir for 20 minutes, and perform homogenization. The homogenization pressure is 250 bar (first adjust the secondary pressure to 50 bar, Then rise to 250bar), add the remaining standardized milk and ingredient...

Embodiment 3

[0048] Formula: 350 parts of milk, 2 parts of lipase (enzyme activity is 2400FCCLU / g), 1.2 parts of sodium carboxymethylcellulose, 1 part of lactic acid, 2.5 parts of citric acid, 0.5 parts of essence, 50 parts of white sugar, and 592.8 parts of ingredient water .

[0049] The preparation method of the invention comprises the following steps in sequence:

[0050] (1) Raw milk whose temperature does not exceed 8°C is heated to 45°C for separation, and the fat content of the cream is 40%;

[0051](2) adding lipase to the cream for hydrolysis for 3 hours, heating up to 80° C., and performing heat treatment for 20 minutes;

[0052] (3) According to the requirements of the index, add skim milk, stir and mix well, and then cool to 8°C;

[0053] (4) Formulated milk compositions;

[0054] (1) Mix white sugar and sodium carboxymethyl cellulose evenly, take an appropriate amount of ingredients and heat them to 80°C with water, slowly add the mixture, stir and dissolve continuously fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com