Improved adhering fastener mechanism for paper diaper

A technology of diapers and sticking sheets, which is applied in the field of improving the hook and loop mechanism, which can solve the problems of high production cost of the stick and buckle mechanism, hard glossy plastic film material, poor hand feeling and visual effect, etc., so as to avoid waking up or frightening the baby and improve the visual effect Soft, soft-textured effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

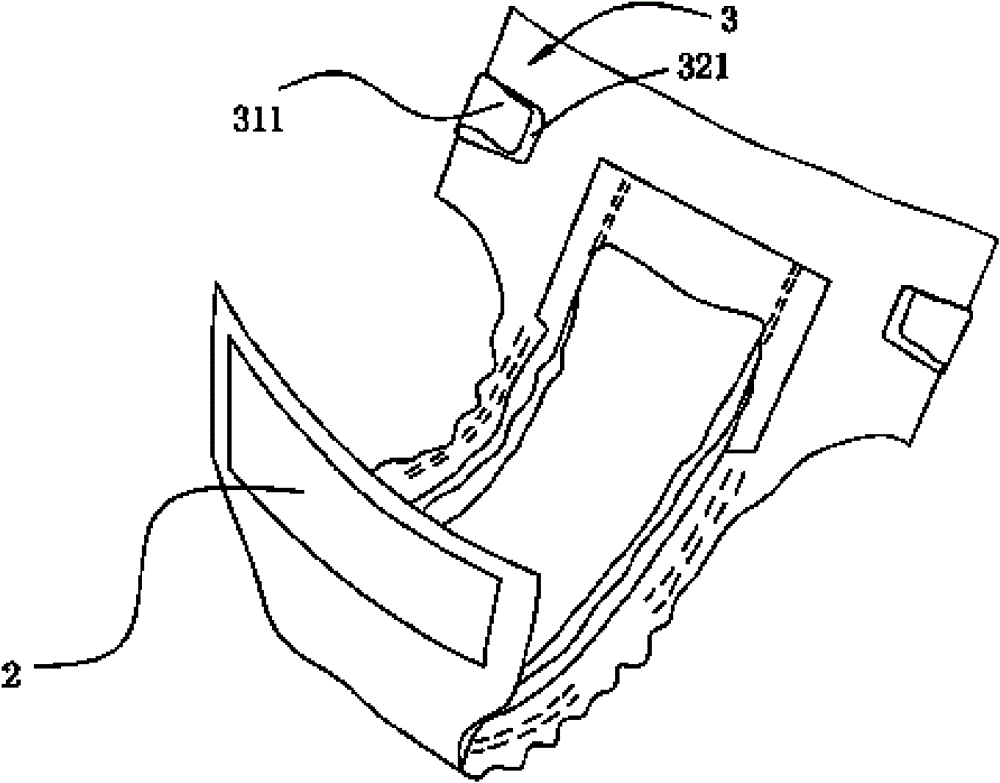

[0029] Such as figure 1 As shown in , the fastening mechanism for diapers includes a front waist sticker 2 and two stickers 3 arranged on the diapers.

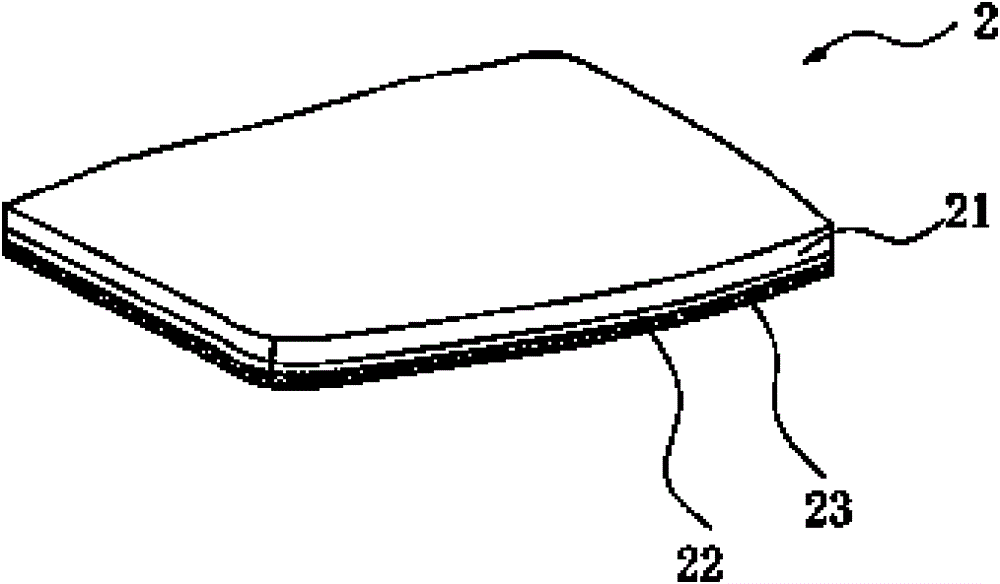

[0030] Such as figure 2 As shown in , the front waist sticker 2 is a sheet-like strip body, which consists of a semi-adhesive layer 21, a matte plastic film layer 22 and a hot-melt adhesive layer that are sequentially fixed by the coating of a release agent material. 23, and bonded to the outer surface of the front end of the diaper through the hot melt adhesive layer 23.

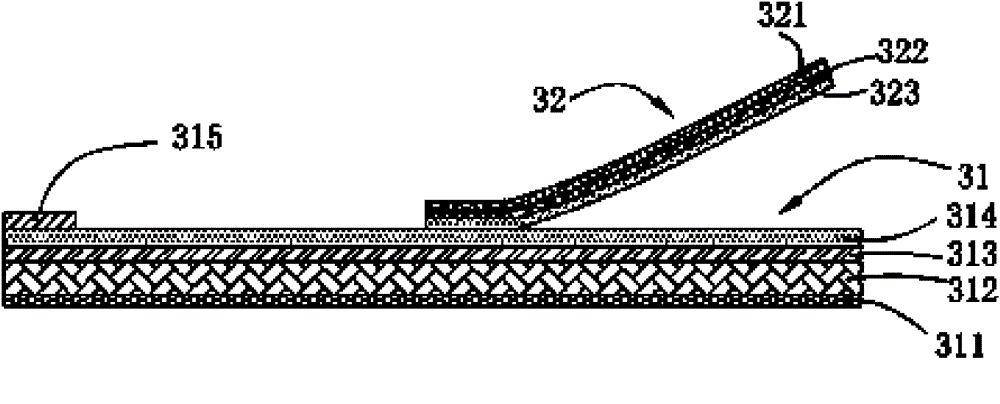

[0031] Such as image 3 and Figure 4 As shown in , the adhesive sheet 3 includes a liner film 32 and a base film 31, the liner film 32 is composed of a silicone oil layer 321 fixed in sequence, a plastic film layer 322 and a hot melt adhesive layer 323, and the base film 31 is fixed in sequence A silicone oil layer 311 (provides anti-adhesive performance), a non-woven fabric layer 312 for providing a soft outer surface, a PP coating layer 313 and a ho...

Embodiment 2

[0038] Such as Figure 5 As shown in , the difference between Example 2 and Example 1 is that the adhesive sheet bottom film 31a uses a PE film layer 313a with a thickness of 8-40 μm to replace the PP coating film 313 in the adhesive sheet 3 . The structure of the remaining parts and the materials used are exactly the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com