Vibration-molding-based cement stabilized macadam mixing ratio design method

A technology of cement stabilizing crushed stone and mixing ratio design, which is applied in chemical instruments and methods, mixing operation control, mixing operation control device, etc. and other problems, to achieve the effect of improving the traffic capacity and the level of safety services, significant economic and social benefits, and good road performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

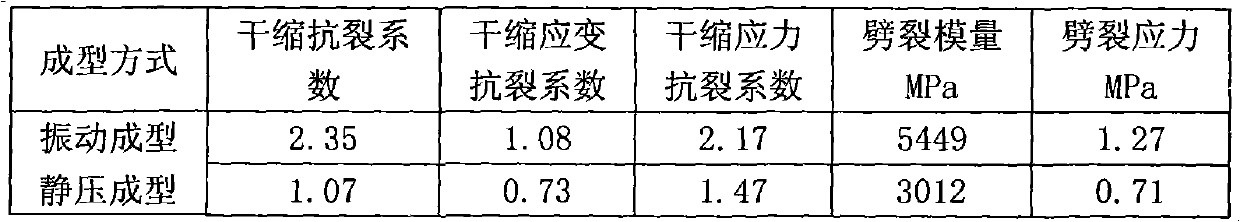

[0028] A method for designing the proportion of cement-stabilized crushed stone based on vibration forming, the specific steps of which are as follows:

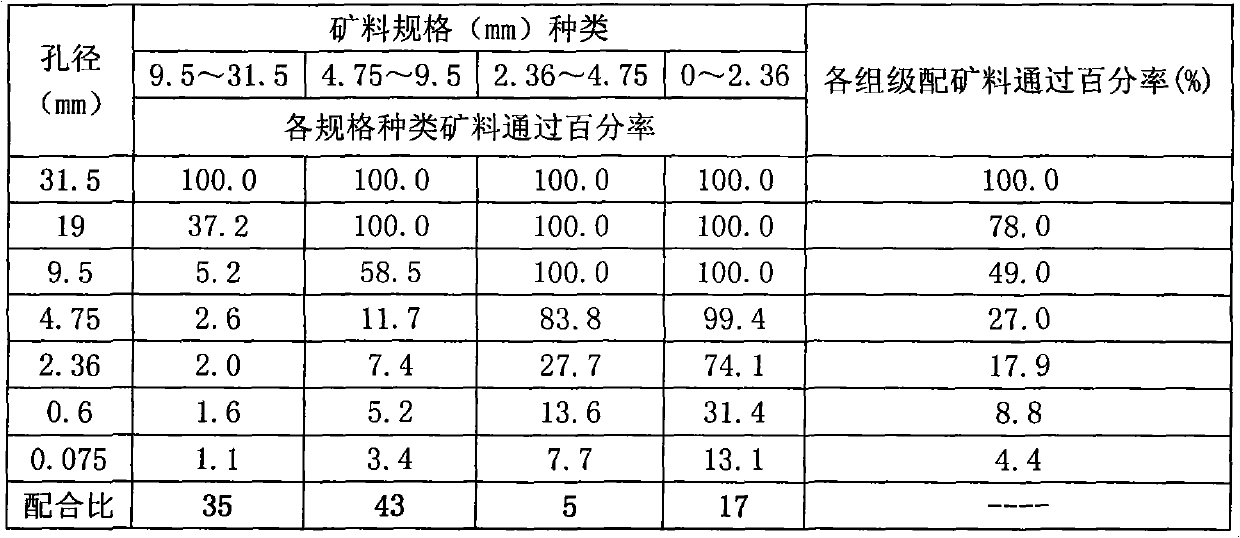

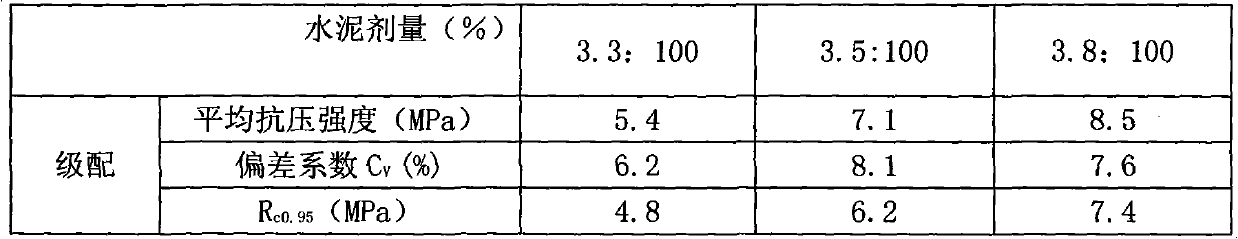

[0029] (1) Prepare optimized skeleton-dense graded aggregates, the gradation of the optimized skeleton-dense graded aggregates is: aggregates with particle diameters less than 31.5mm account for 100% of the total mass of the graded aggregates ; Aggregate particle size less than 19mm accounts for 75-85% of the total mass of the graded aggregate; aggregate particle size less than 9.5mm accounts for 42-54% of the total mass of the graded aggregate; Aggregate smaller than 4.75mm accounts for 25-35% of the total mass of the graded aggregate; aggregate particle size less than 2.36mm accounts for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com