Halogen-free fire resistance resin composite and application thereof

A resin composition and flame retardancy technology, applied in chemical instruments and methods, printed circuits, printed circuit manufacturing, etc., can solve problems such as the inability to meet halogen-free environmental protection requirements, and achieve excellent heat resistance, good heat resistance, The effect of excellent heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

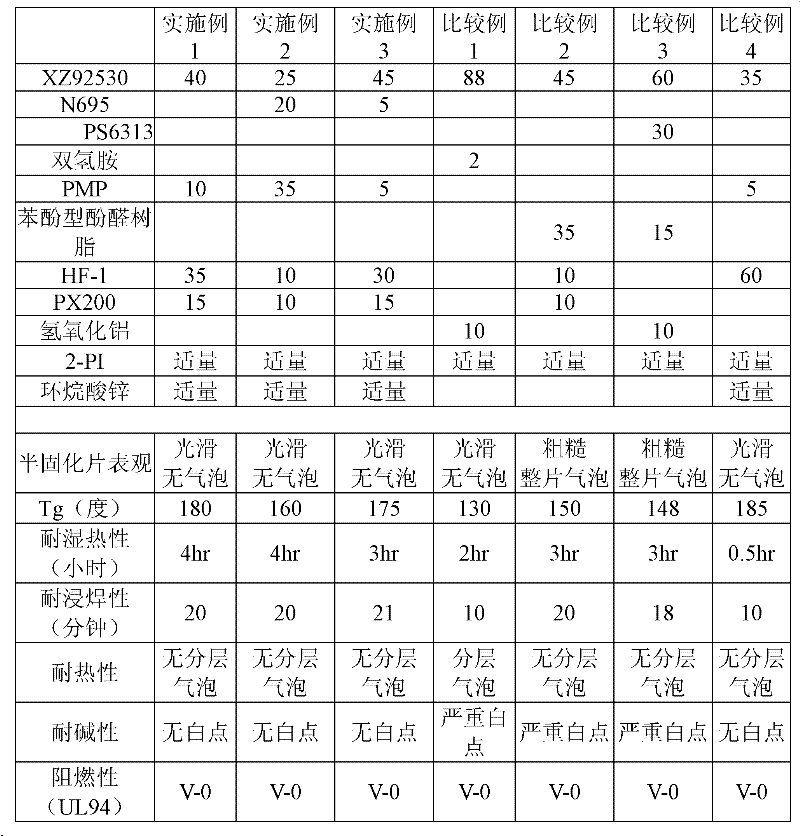

[0033] Use 40 parts of XZ92530, 10 parts of PMP, 35 parts of HF-1, 15 parts of PX200 supplemented with catalyst 2-PI and zinc naphthenate, use 80 parts of MEK to dissolve the above compounds, and prepare a glue with a suitable viscosity. Use 2116-type electronic grade glass cloth to soak the glue, and bake it in an oven at 155 degrees to remove the solvent to obtain a B-stage prepreg.

[0034] Laminate eight prepregs and two one-ounce electrolytic copper foils together, and laminate them with a hot press to obtain a double-sided copper-clad laminate (a laminate for printed circuits). The lamination conditions are as follows: 1. When the material temperature is 80-120 degrees, the heating rate is controlled at 1.0-3.0 degrees / minute; 2. The pressure is set to 20kg / cm 2 ; 3, curing temperature at 190 degrees, and maintain this temperature for 90 minutes. The corresponding properties are shown in Table 1.

Embodiment 2

[0036] Use 25 parts of XZ92530, 20 parts of N695, 35 parts of PMP, 10 parts of HF-1, 10 parts of PX200 supplemented with catalyst 2-PI and zinc naphthenate, use 80 parts of MEK to dissolve the above compounds, and adjust to a suitable viscosity glue. Use 2116-type electronic grade glass cloth to soak the glue, and bake it in an oven at 155 degrees to remove the solvent to obtain a B-stage prepreg.

[0037] Laminate eight prepregs and two one-ounce electrolytic copper foils together, and laminate them with a hot press to obtain a double-sided copper-clad laminate. The lamination conditions are as follows: 1. When the material temperature is 80-120 degrees, the heating rate is controlled at 1.0-3.0 degrees / minute; 2. The pressure is set to 20kg / cm2; 3. The curing temperature is 190 degrees, and maintain this temperature for 90 minutes . The corresponding properties are shown in Table 1.

Embodiment 3

[0039] Use 45 parts of XZ92530, 5 parts of N695, 5 parts of PMP, 30 parts of HF-1, 15 parts of PX200 supplemented with catalyst 2-PI, zinc naphthenate, use 100 parts of MEK to dissolve the above compounds, and adjust to a suitable viscosity glue. Use 2116-type electronic grade glass cloth to soak the glue, and bake it in an oven at 155 degrees to remove the solvent to obtain a B-stage prepreg.

[0040] Laminate eight prepregs and two one-ounce electrolytic copper foils together, and laminate them with a hot press to obtain a double-sided copper-clad laminate. The lamination conditions are the same as in Example 1, and the corresponding properties are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com