Insulating tape

A technology of insulating tape and cross-linking agent, applied in polyurea/polyurethane adhesives, epoxy resin adhesives, film/sheet adhesives, etc., can solve problems such as machine performance degradation, and achieve excellent appearance retention Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] When preparing the above-mentioned acrylic polymer, a polymerization initiator such as a thermal polymerization initiator or a photopolymerization initiator (photoinitiator) can be used depending on the type of polymerization reaction. The polymerization initiators may be used alone or in combination of two or more. Generally, a thermal polymerization initiator is often used as a polymerization initiator in a solution polymerization method, and a photopolymerization initiator is often used as a polymerization initiator in an active energy ray polymerization method, but they are not particularly limited.

[0046] As said thermal polymerization initiator, an azo type polymerization initiator, a peroxide type polymerization initiator, a redox type polymerization initiator etc. are mentioned, for example. Examples of the aforementioned azo-based initiator include: 2,2'-azobisisobutyronitrile (hereinafter sometimes referred to as AIBN), 2,2'-azobis-2-methylbutyronitrile (her...

Embodiment

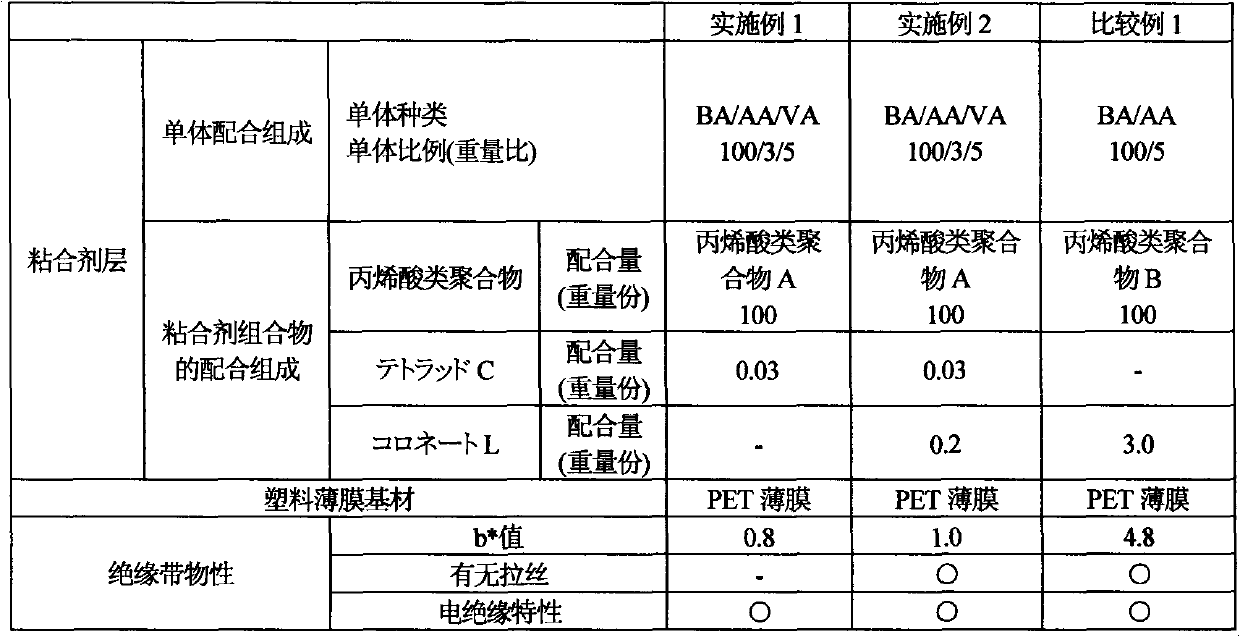

[0079] Hereinafter, the present invention will be described in more detail based on examples, but the present invention is not limited to these examples. In addition, in the following description and Table 1, the compounding amount (addition amount) of Coronet L is expressed in terms of solid content (parts by weight).

manufacture example

[0081] 100 parts by weight of n-butyl acrylate, 3 parts by weight of acrylic acid and 5 parts by weight of vinyl acetate as monomer components, 0.2 parts by weight of 2,2'-azobisisobutyronitrile as a polymerization initiator, and 250 parts by weight of toluene were put into the separable flask, and stirred for 1 hour while introducing nitrogen gas. In this way, after the oxygen in the polymerization system was removed, the temperature was raised to 80° C. for 7 hours, and then toluene was added to adjust the concentration to obtain an acrylic polymer solution with a solid content concentration of 20% by weight (sometimes referred to as “acrylic polymer solution A”). ). The weight average molecular weight of the acrylic polymer in this acrylic polymer solution A (it may be called "acrylic polymer A") was 500,000.

[0082] Production example of acrylic polymer B

[0083] 100 parts by weight of n-butyl acrylate and 5 parts by weight of acrylic acid as a monomer component, 0.5 p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com