Rotary electrodeposition method and device for producing ring-shaped diamond band saw

An electrodeposition device and diamond technology, applied in the direction of manufacturing tools, electrolytic coatings, stone processing equipment, etc., can solve the problems of unusable saw blades, reduced tool life, buried, etc., to improve current efficiency, reduce trapped air bubbles, and eliminate temperature inconsistent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

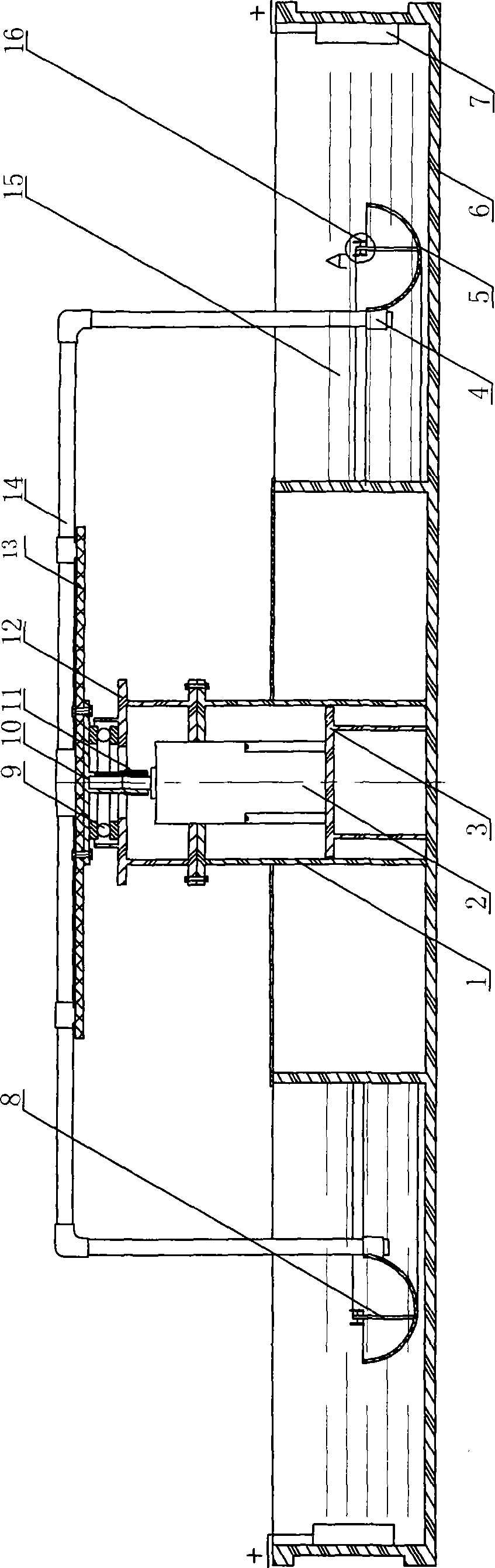

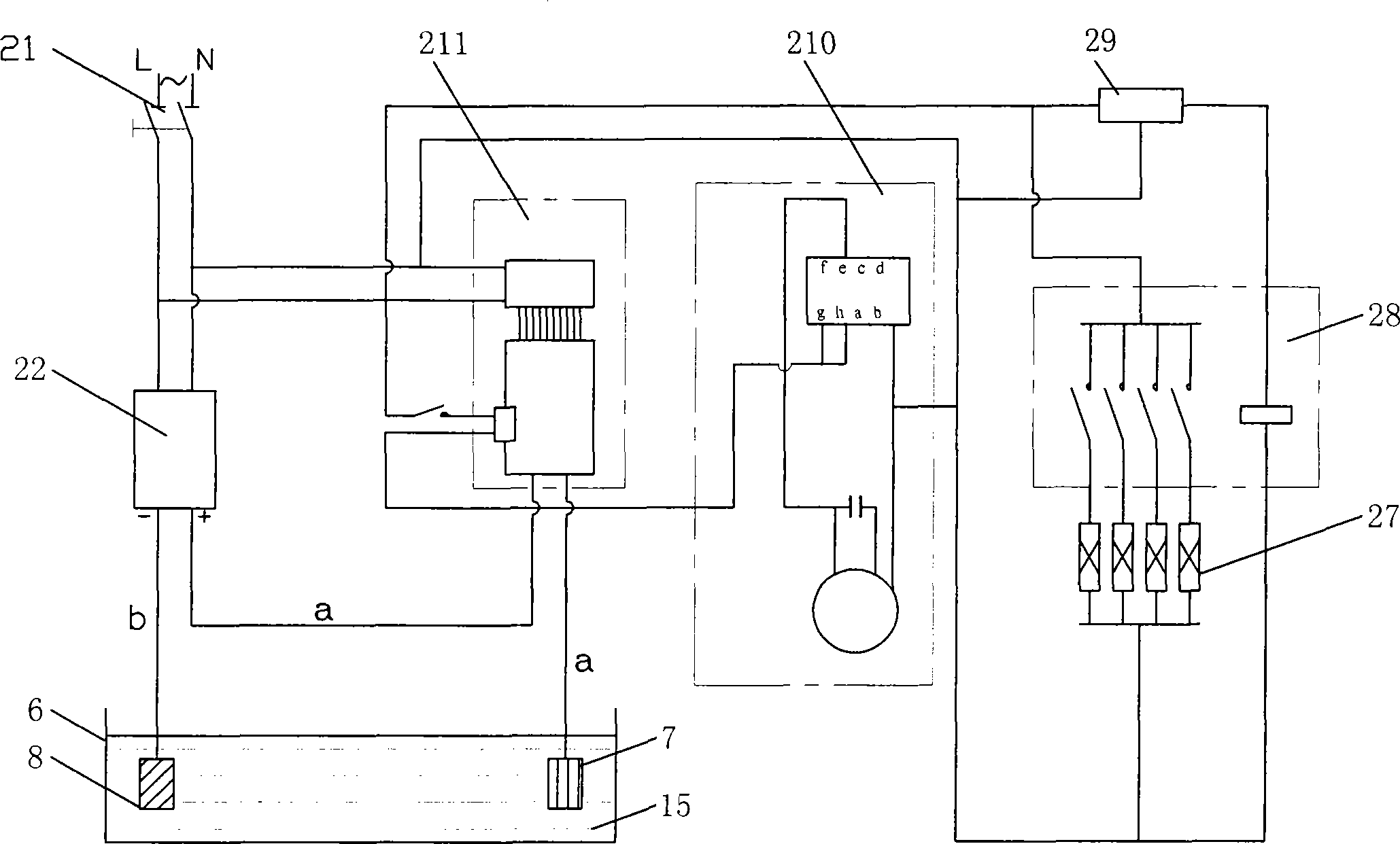

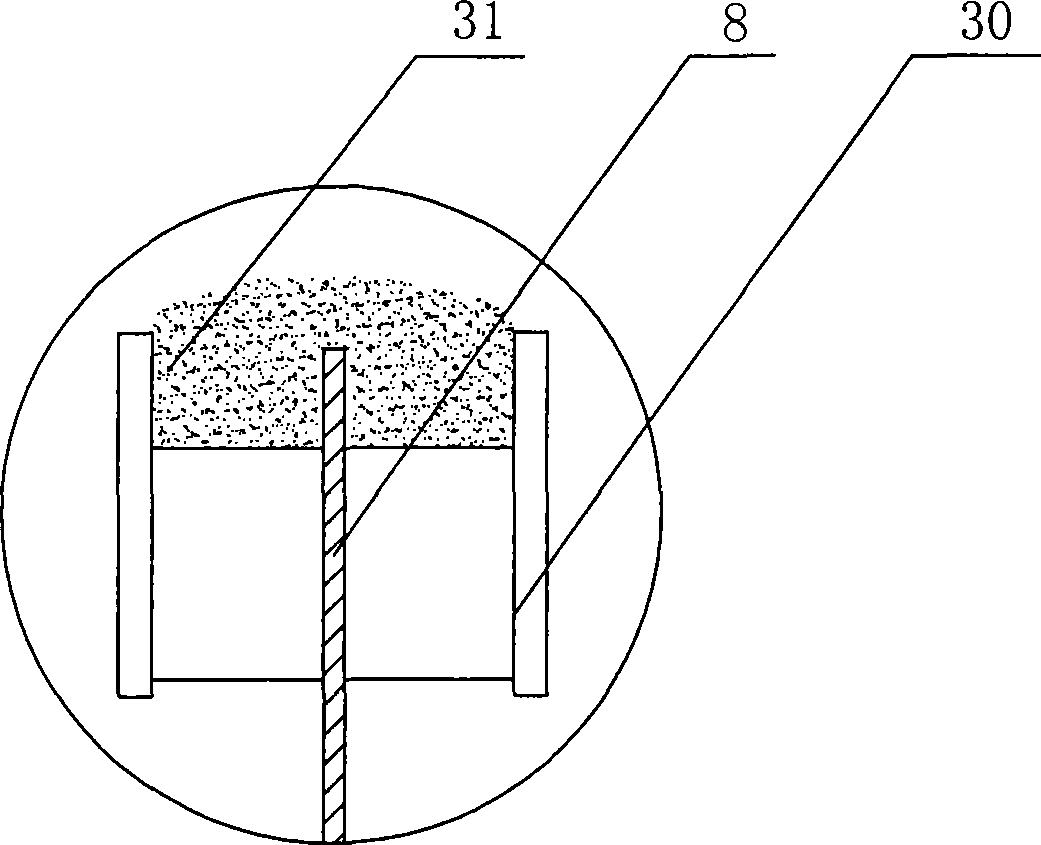

[0042] Such as figure 1 Shown is an embodiment of a structure of a rotary electrodeposition device for manufacturing a circular diamond band saw provided by the present invention, including:

[0043] A frame, the frame includes two parts: one part is a positioning frame 1, a bracket 3 is arranged on the positioning frame 1, and a motor 2 is arranged on it, and the output shaft of the motor is upward. The motor can be a micro motor with its own The reducer forms a slow motor with a lower rotational speed, which can be 1-10 rpm. The other part is a support frame 12, and the support frame 12 is fixed on the positioning frame 1; a pressure bearing 9 is arranged on the support frame 12, and a flange plate 10 with a shaft sleeve is arranged on the pressure bearing 9. On the flange plate The shaft sleeve and the motor output shaft form a circumferential connection through a key connection structure, so that the motor drives the flange 10 to rotate;

[0044] a bracket, arranged on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com