Radio frequency identification management system for polycrystalline diamond cutter

A polycrystalline diamond and radio frequency identification technology, which is applied in the field of coding systems, can solve the problems of inability to guarantee the integrity of data information, inconvenient data processing and management, and problems with data accuracy, so as to be easy to use in a wide range and realize over-travel protection. function, the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

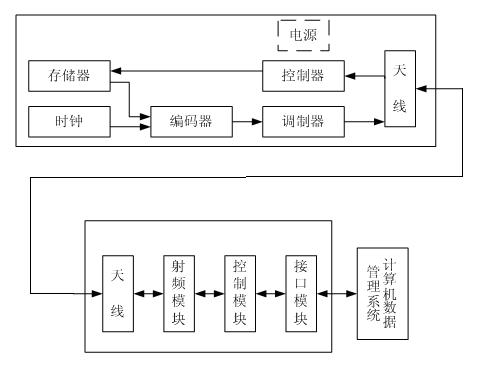

[0054] Embodiment 1: The polycrystalline diamond tool radio frequency identification management system includes a polycrystalline diamond tool (7) and a computer (12) as a server, and is characterized in that a label (9) is attached to the polycrystalline diamond tool (7) ), the tag (9) is composed of a chip connected to the antenna, the chip of the tag (9) writes the code of the polycrystalline diamond tool; a near-field antenna (8) is installed on the machine tool through an antenna fixture, which can adjust the near-field The position of the antenna (8) makes it close to the label (9) of the tool; a reader (10) is connected with the feeder (3) through the cable (13), and the near-field antenna on the antenna fixture reads The coded information of the polycrystalline diamond tool on the label (9), and then transmit the coded information via the Internet or local area network or 3G wireless network, and send it to the computer (12) for data processing through the radio frequen...

Embodiment 2

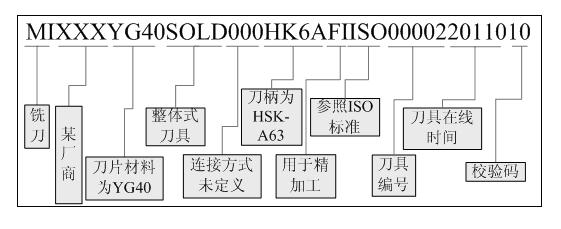

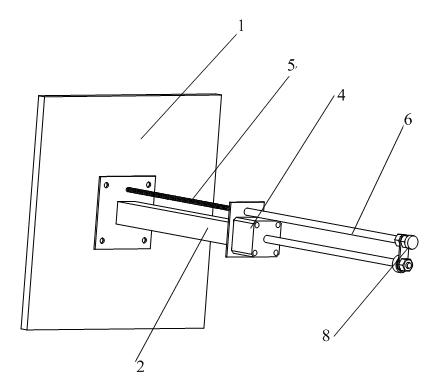

[0055] Embodiment 2: This embodiment is basically the same as Embodiment 1. The special feature is that the code written on the label (9) has two parts: a fixed code and a variable code; the fixed code includes the manufacturer, material, Type, standard; the variable code is the information of the online time of the tool, including the online time, the code corresponding to the first tool setting parameter, and the check code. The structure of the antenna fixture is as follows: a mounting plate is fixed on the side wall of the machine tool, a linear motor mounting frame is fixedly mounted on the mounting plate, a linear motor is mounted on the linear motor mounting frame, and the linear motor links two parallel The extension rods of the two extension rods are fixedly connected to the near-field antenna at the ends of the two extension rods; the extension rods are hollow cylindrical support rods, and the feeder line of the near-field antenna passes through the center of the holl...

Embodiment 3

[0056] Embodiment 3: Install the near-field antenna (8) and related feeder (5) on the extension rod (6), and fix them with screws. Fix the linear motor bracket (2) on the side wall (1) of the machine tool, and adjust it according to the pose of the tool when changing the tool. After the adjustment is completed, connect the linear motor (4), the linear motor driver (14) and the cable (13), so that the antenna fixture can be energized and operated. The near-field antenna (8), the feeder (5), the feeder (3), the reader (10) are connected, and the server (12) is connected through the Internet (11), so that it becomes a complete system. Adhere the anti-metal label (9) to the polycrystalline diamond cutter (7) to ensure its bonding strength. Use the server (12) to program, refer to the coding method proposed in this patent, respectively operate the reader (10) and the linear motor driver (14) through the Internet (11), and operate the tag (9) through the antenna (8) Writing / readin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com