Film gauffer removing device, film tension adjusting method and film gauffer removing method

A thin-film and wrinkle-removing technology that is used in thin-film/thick-film capacitors, thin-film handling, transportation and packaging to reduce entanglement and prevent misalignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

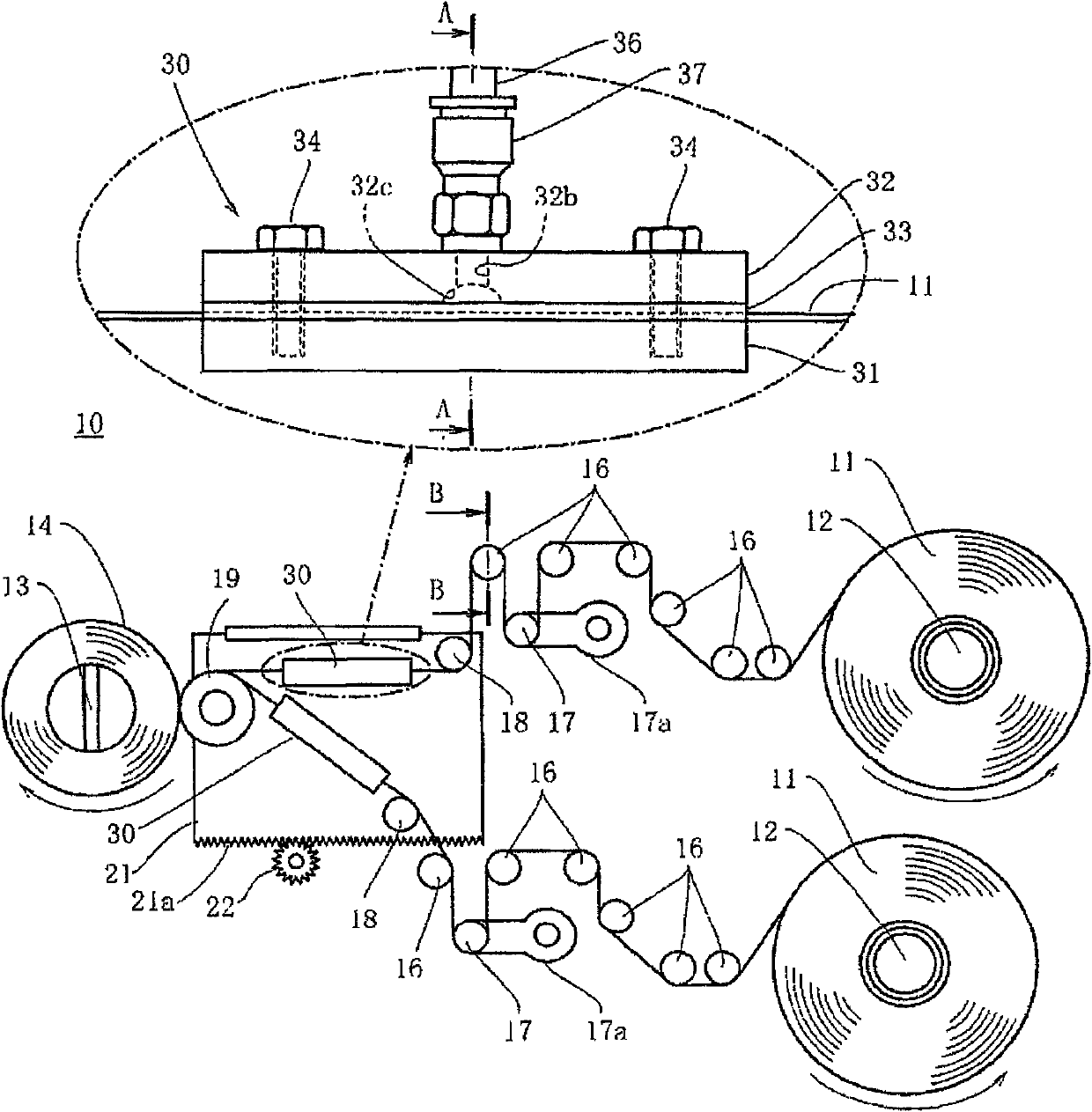

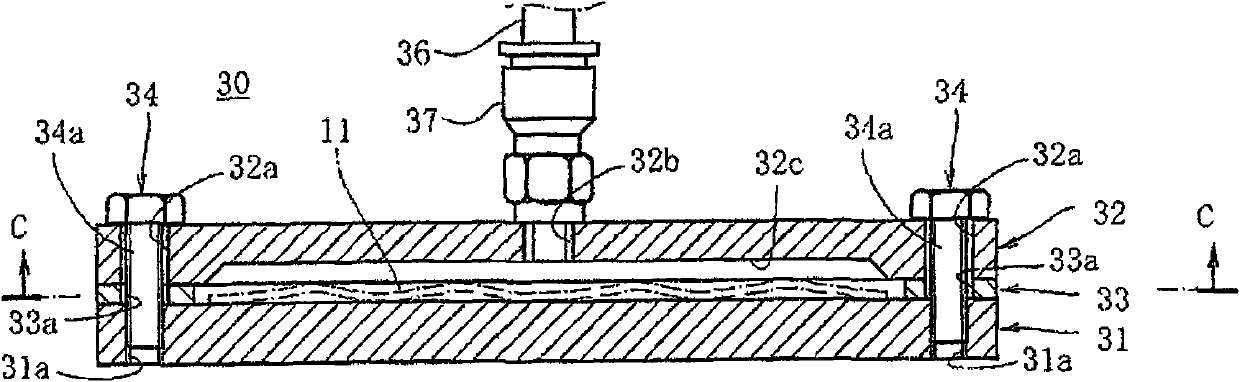

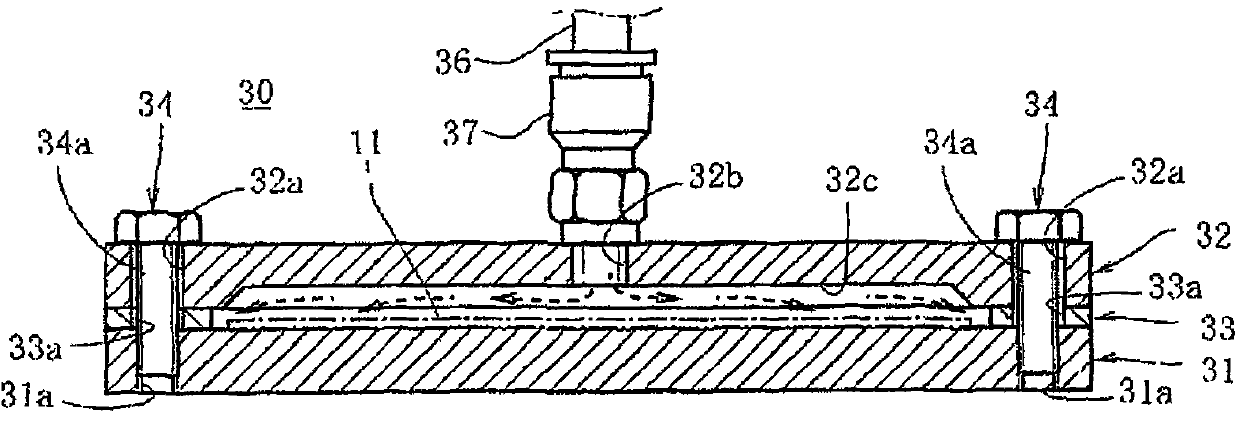

[0037] Next, the best mode for carrying out the present invention will be described with reference to the drawings.

[0038] figure 1 A film winding device 10 according to an embodiment of the present invention is shown. This winding device 10 includes a supply unit 12 that feeds out a strip-shaped film 11 wound around a bobbin or bobbin (not shown). The supply part 12 in this embodiment refers to an unwinding shaft configured to be able to install the metallized film 11 wound on a bobbin or bobbin not shown in the figure. The metallized film 11 is formed in a group of two, superimposed in pairs and then wound. Therefore, the unwinding shaft 12 as the supply part also has a pair, that is, two, so that two groups of strip-shaped metallized films 11 can be installed respectively. Here, as the metallized film 11 , a film having a width of 80 mm and a thickness of 3 μm formed by forming a metal vapor-deposition electrode on one side of a dielectric film made of polypropylene is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com