Neon lamp automatic optometry machine

An automatic optometry, neon lamp technology, applied in the direction of measurement/testing in the manufacturing process, can solve the problems of high skill requirements for employees, limited production quantity, high labor cost, etc., to achieve simple structure, fewer employees, and production efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further explained below in conjunction with the accompanying drawings.

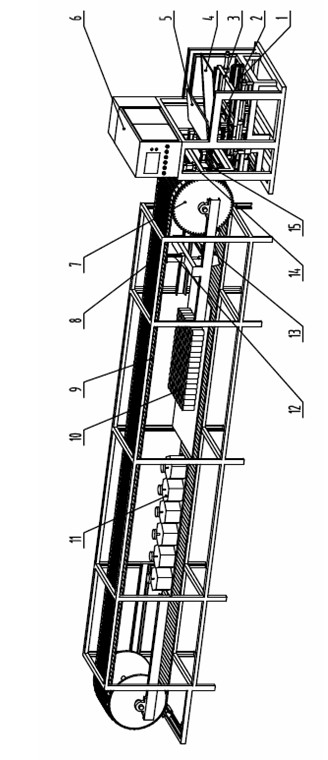

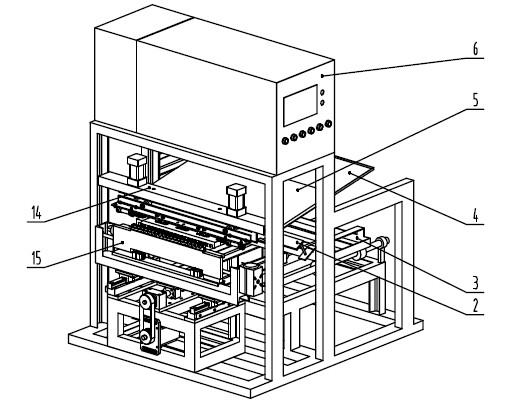

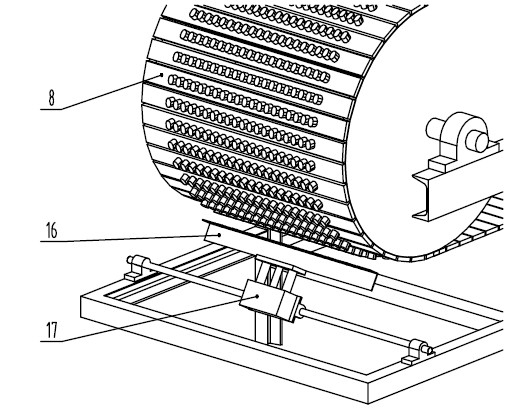

[0018] like figure 1 Shown is the neon lamp automatic optometry machine of the present invention. The neon lamp automatic optometry machine includes a console 6, an automatic feeding device, an activation seasoning device and an automatic bubble collection device; the automatic feeding device is arranged at the front end of the activation aging device, and automatically assembles the aging neon lamps to be activated for the activation aging device ; The automatic foam collecting device is arranged at the back end of the activation aging device, and automatically collects and activates the aging neon lamp; the described console includes electrical centralized control switches and circuits, which are used for centralized control of the automatic feeding device, activation of the aging device And the opening and closing of the cylinder and power supply of the automatic f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com