Locking device in solar module framing and cornering device

A technology of solar cells and locking devices, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of limited use of promotion, high labor intensity, high energy consumption, etc., achieve huge economic and social benefits, and improve work efficiency. and production efficiency, the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

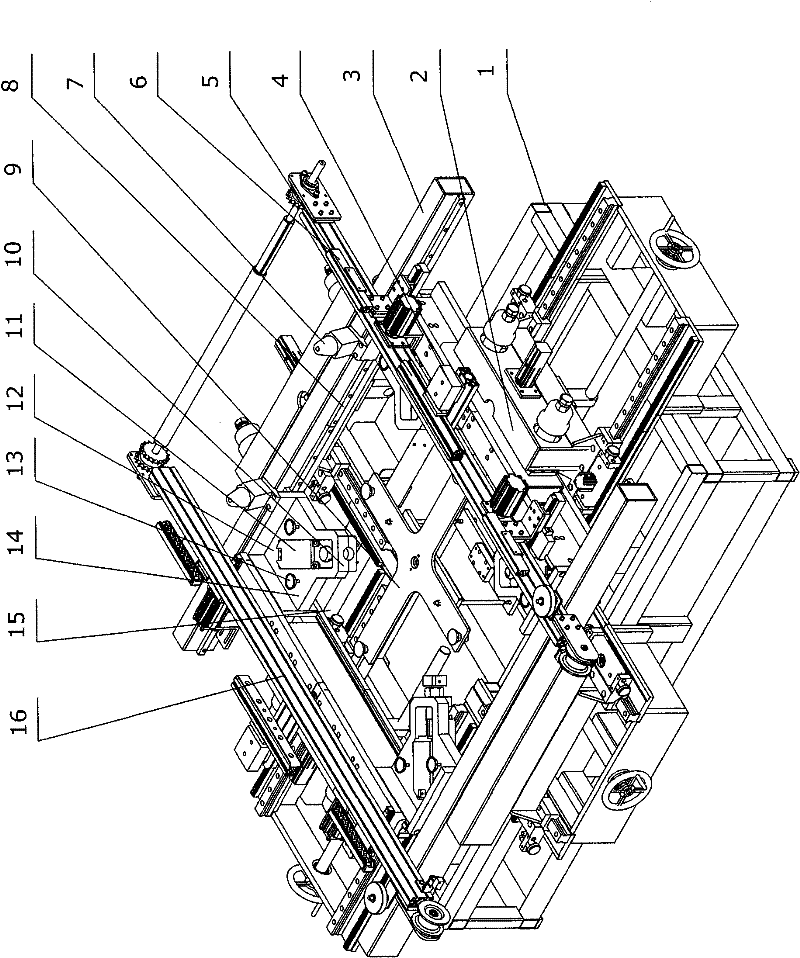

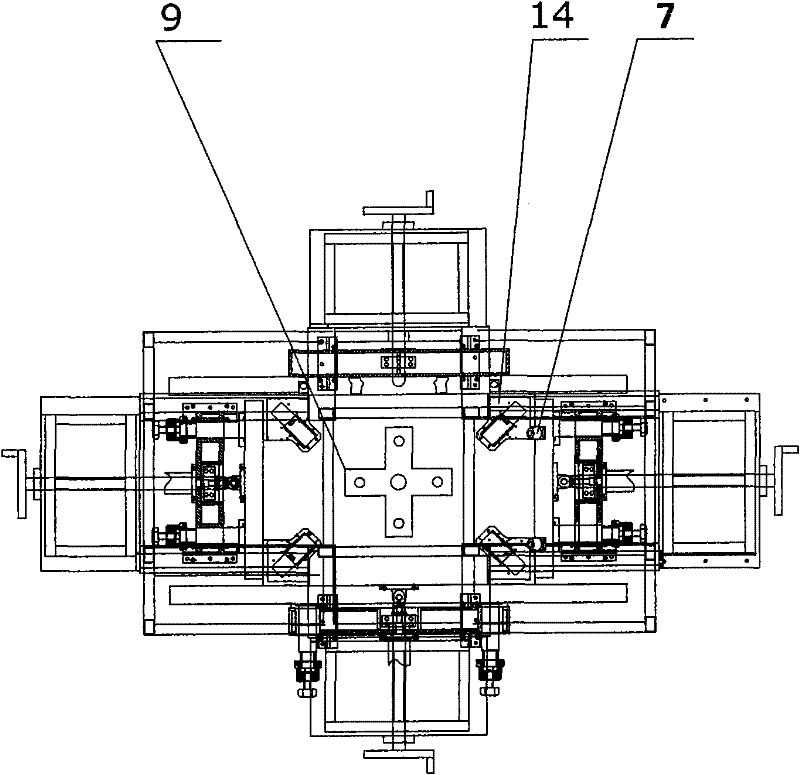

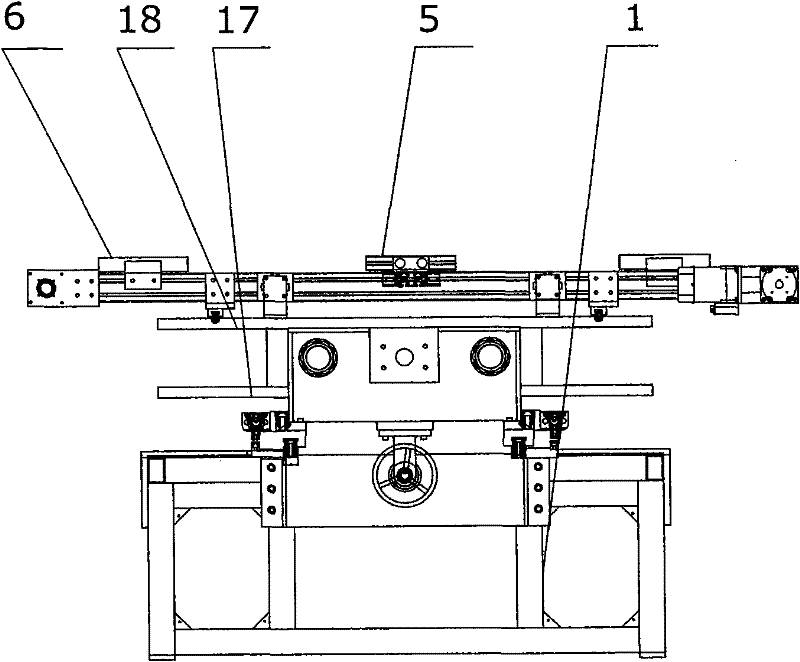

[0016] The present invention comprises frame 1, and one side of frame 1 is provided with movable support 2, and the top of frame 1 is provided with group frame crossbeam 3, and movable support 2 is fixedly connected with group frame crossbeam 3; The upper guide plate 18 and the lower guide plate 17 link to each other, and the lower guide plate 17 fixes the group angle bottom plate 15 of the group angle oil cylinder 10 to link to each other with the group frame beam 3, and is fixed on the group angle bottom plate 15 on the inner peripheral angle of the frame 1 to be provided with a group Angle mechanism14.

[0017] The group angle mechanism 14 is connected by the group angle knife 11 on the group angle plate 12 and the group angle oil cylinder 10 fixed on the group angle base plate 15, and the group angle plate 12 is provided with a support suction cup 13; the group angle plate 12 The number is four.

[0018] The front end of the group angle body in the group angle knife 11 ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com