Inner-tank heating structure of electric kettle

A technology of electric kettle and heating structure, which is applied to water-boiling utensils, special materials for cooking utensils, kitchen utensils, etc., can solve the problems of low heat exchange efficiency, cumbersome operation, complex structure, etc., achieves low rejection rate and improves heat exchange. Efficient, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

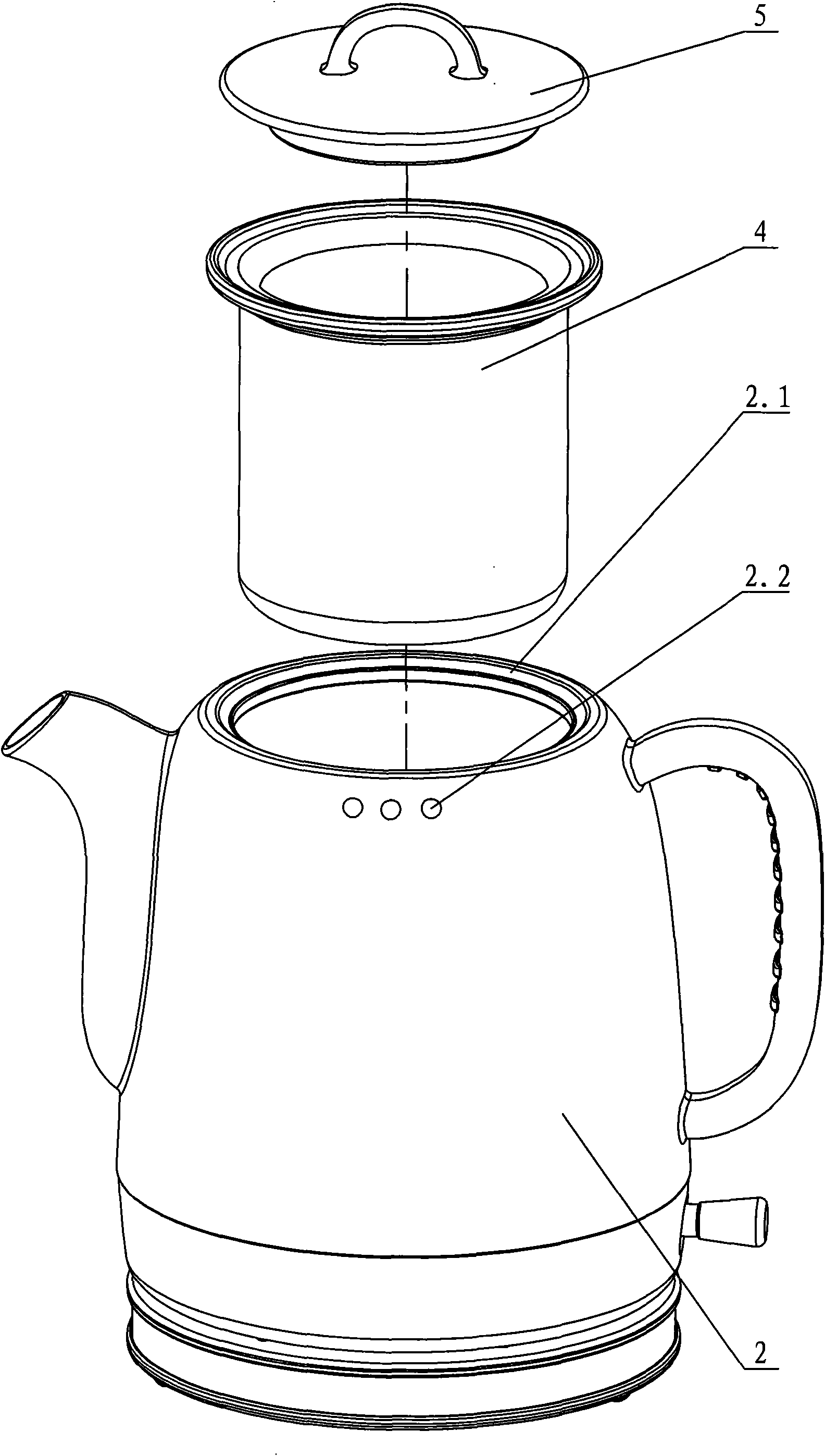

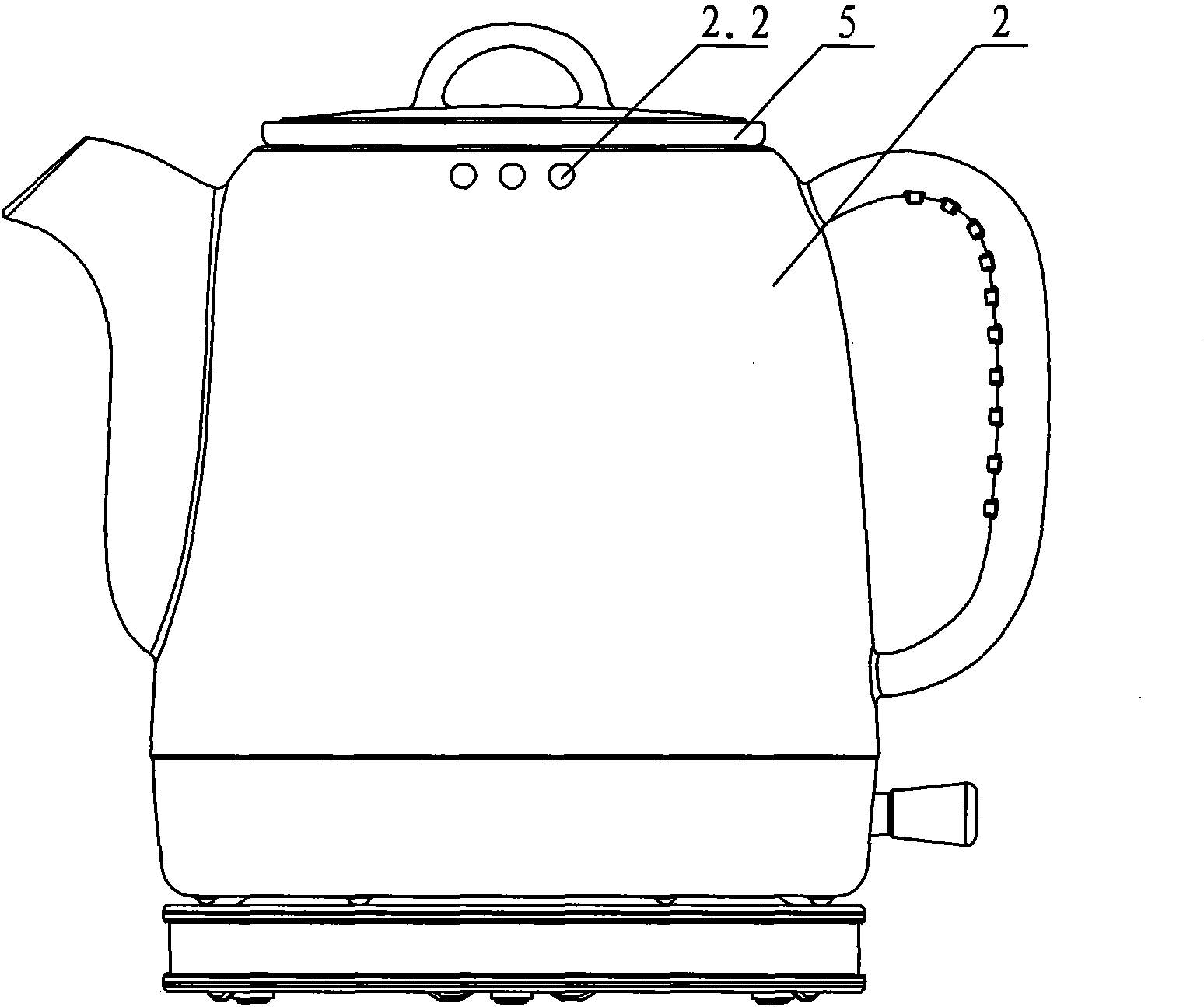

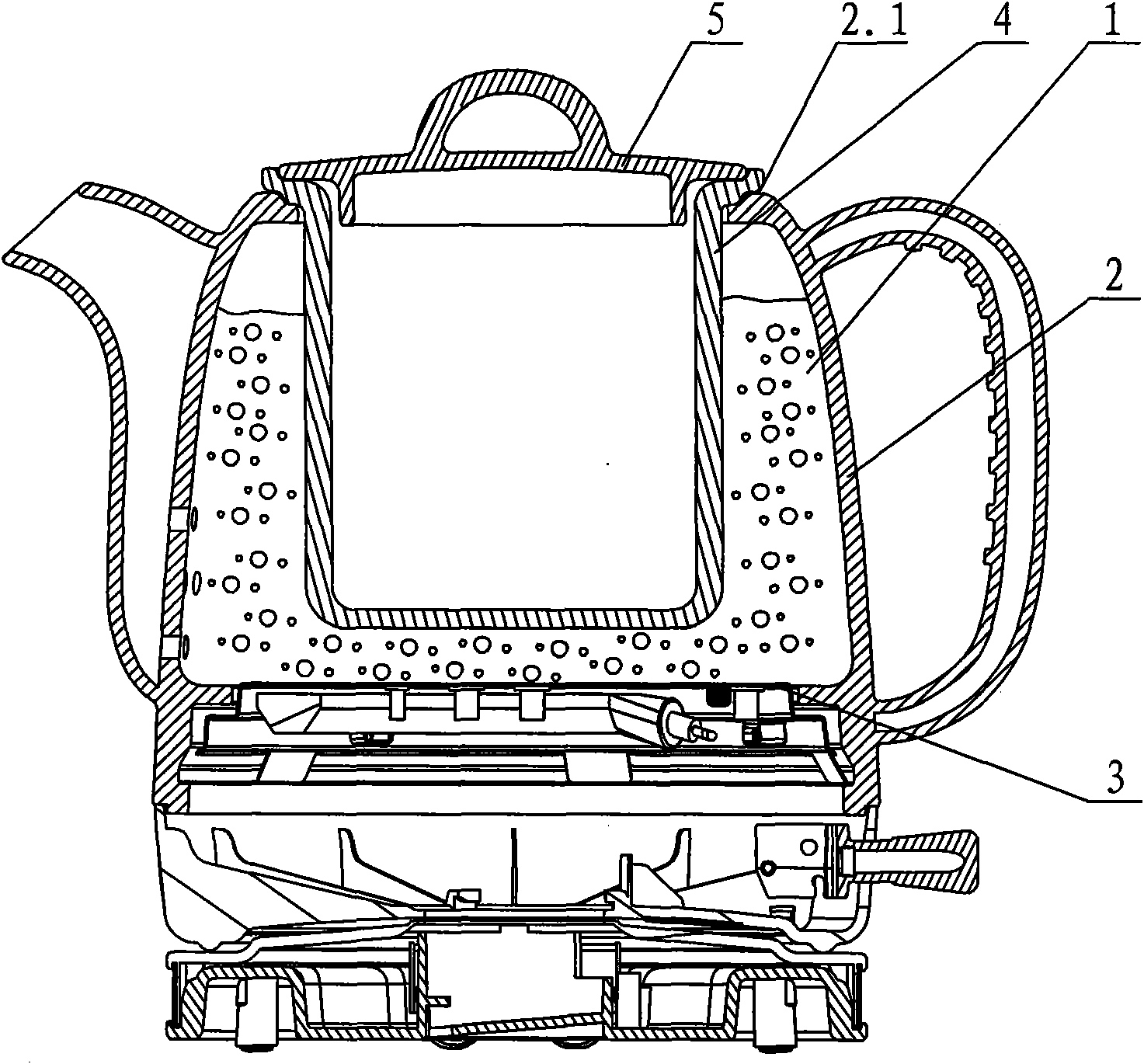

[0020] see Figure 1-Figure 3 , the inner tank heating structure of this electric kettle includes a pot cover 5 and a pot body 2. A heating plate assembly 3 is arranged on the pot body 2. The temperature control part is electrically connected, and the temperature control part is an electronic temperature controller. The kettle body 2 is provided with a detachable liner 4, which is made of ceramics. The liner 4 is hollow, forming a cavity for holding food. The liner 4 is inserted into the kettle body 2 , and the pot cover 5 is sealed and connected with the kettle body 2 or the liner 4 . The bottom of the pot cover 5 extends a fixed boss, which cooperates with the opening of the mouth of the kettle body 2 / liner 4 and is fixed, and the top of the pot cover 5 is provided with a handle hole.

[0021] A positioning groove 2.1 is extended from the spout of the pot body 2, and the opening of the inner tank 4 is provided with a curling matching the positioning concave platform, and ...

no. 2 example

[0024] A positioning groove 2.1 extends from the mouth of the kettle body 2, and a ring-shaped convex platform is arranged at the corresponding position of the inner tank 4 and the positioning concave platform. The material of 4 is a purple sand product.

[0025] Others are not described with the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com