Compositions comprising superhydrophilic amphiphilic copolymers and methods of use thereof

An amphiphilic copolymer and super-hydrophilic technology, which can be used in drug combinations, diseases, pharmaceutical formulations, etc., and can solve problems such as poor foaming and cleaning performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0395] example

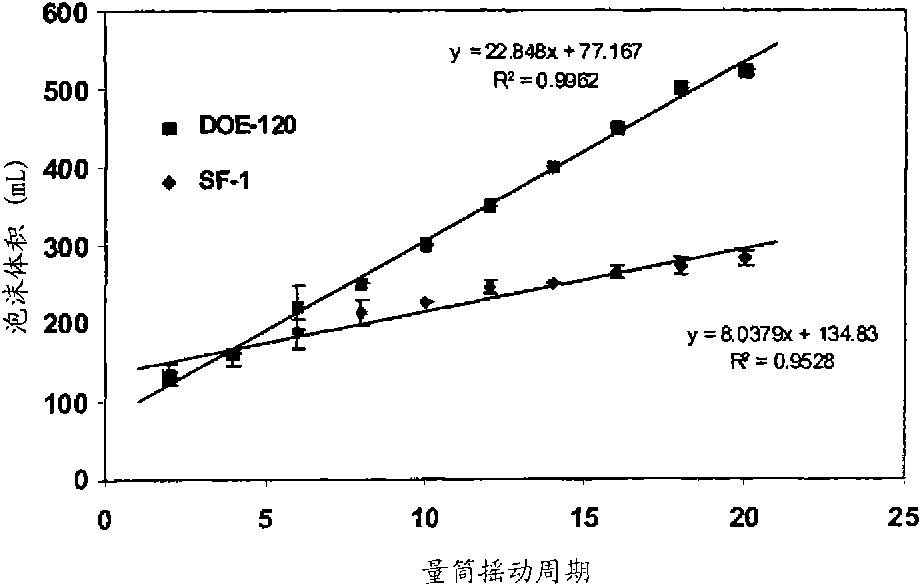

[0396]The following Drop Shape Analysis ("DSA"), Dynamic Light Scattering ("DLS"), Polymer Foam, Formulation Foam, Solution Viscosity, Formulation Flash Foam, and Formulation Viscosity tests were used in the point-of-care test methods and in the Examples below. Specifically, as described above, the DSA test is used to determine to what extent a polymeric material (eg, SAC) in a composition according to the present invention reduces surface tension. The DLS test, Polymer Foam Test and Solution Viscosity can be used to determine whether a particular SAC is suitable to provide reduced irritation and high foaming, and the Formulation Flash Foam Test and Formulation Viscosity Test can be used to determine that a particular composition is capable of producing high foam and and / or provide a degree of beneficial viscosity (which is often desirable for cleaning compositions).

[0397] Unless otherwise specified, the content of each ingredient in the examples and com...

example E1-E6 and comparative example C1-C3

[0421] Examples E1-E6 and Comparative Examples C1-C3: Preparation of polymerized surfactants

[0422] The following polymerized surfactants of Inventive Examples E1-E6 and Comparative Examples C1-C3 were prepared.

[0423] Table 1

[0424]

[0425]

[0426] The preparation of the polymerized surfactant shown in Table 1 is as follows: the hydrolyzed PA-18 in the comparative example C1 is obtained by the following steps: carry out 1-octadecene and maleic anhydride (PA-18 low viscosity low color grade, The reaction of a 1:1 alternating copolymer (commercially available from Chevron Phillips Chemical, LLC) with aqueous sodium hydroxide produces an octadecene / MA copolymer with an average of about 50 amphiphilic repeat units (by weight average based), the mole fraction of the amphiphilic repeating unit is about 100%, and there is a C16 hydrophobic group in the amphiphilic repeating unit.

[0427] The hydrolyzed PA-14 in Comparative Example C2 was obtained by performing t...

example E7-E12 and comparative example C4-C5

[0448] Examples E7-E12 and Comparative Examples C4-C5: Preparation of Simulated Compositions for Dynamic Light Scattering Tests

[0449]The mock compositions of Examples E7 to E12 and Comparative Examples C4 and C5 were prepared for DLS testing. A simulated composition was prepared by separately mixing the specific polymerized surfactant described above with the other ingredients as follows: Water (about 50.0 parts) was added to a beaker equipped with a mechanical stirrer and a hot plate. Sodium methylparaben (and) sodium propylparaben (and) sodium ethylparaben (Nipasept Sodium, Clariant Corp.) powder was then added and stirred until dissolved. Then, the polymerized surfactant was added at a low stirring speed to avoid aeration. Tetrasodium EDTA (Versene XL, Dow Chemical) was added and mixing continued. Provide heating (not to exceed 60° C.) if necessary to obtain a homogeneous solution. If necessary, cool the batch to 25°C while continuing to agitate at medium speed. Ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com