Adsorption tower for testing

An adsorption tower and adsorbent technology, applied in the field of gas turbines, can solve the problems of difficulty in measuring the adsorbent, the purification effect of coke oven gas is inconvenient to replace the adsorbent, etc., and achieve the effect of convenient replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

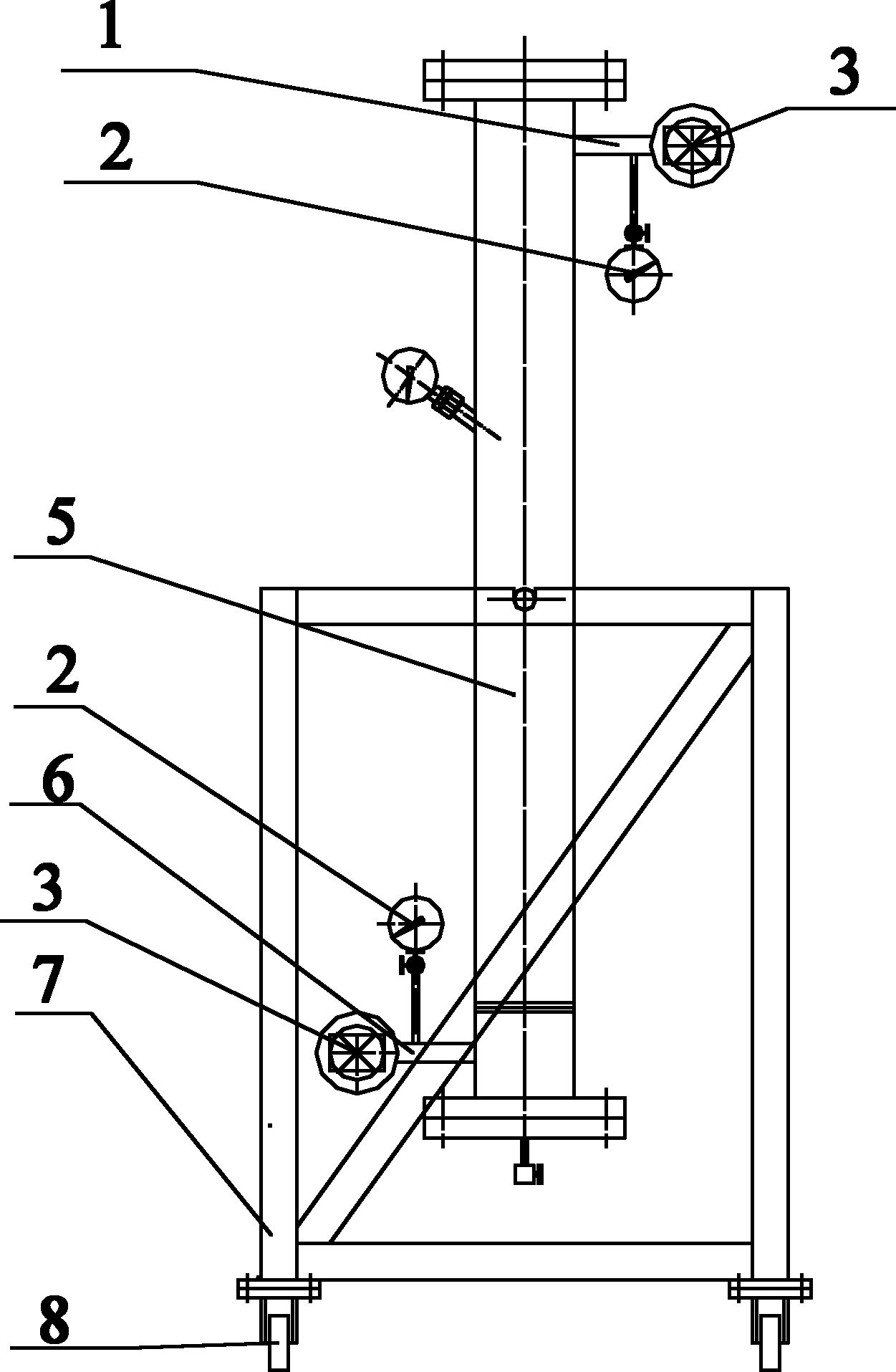

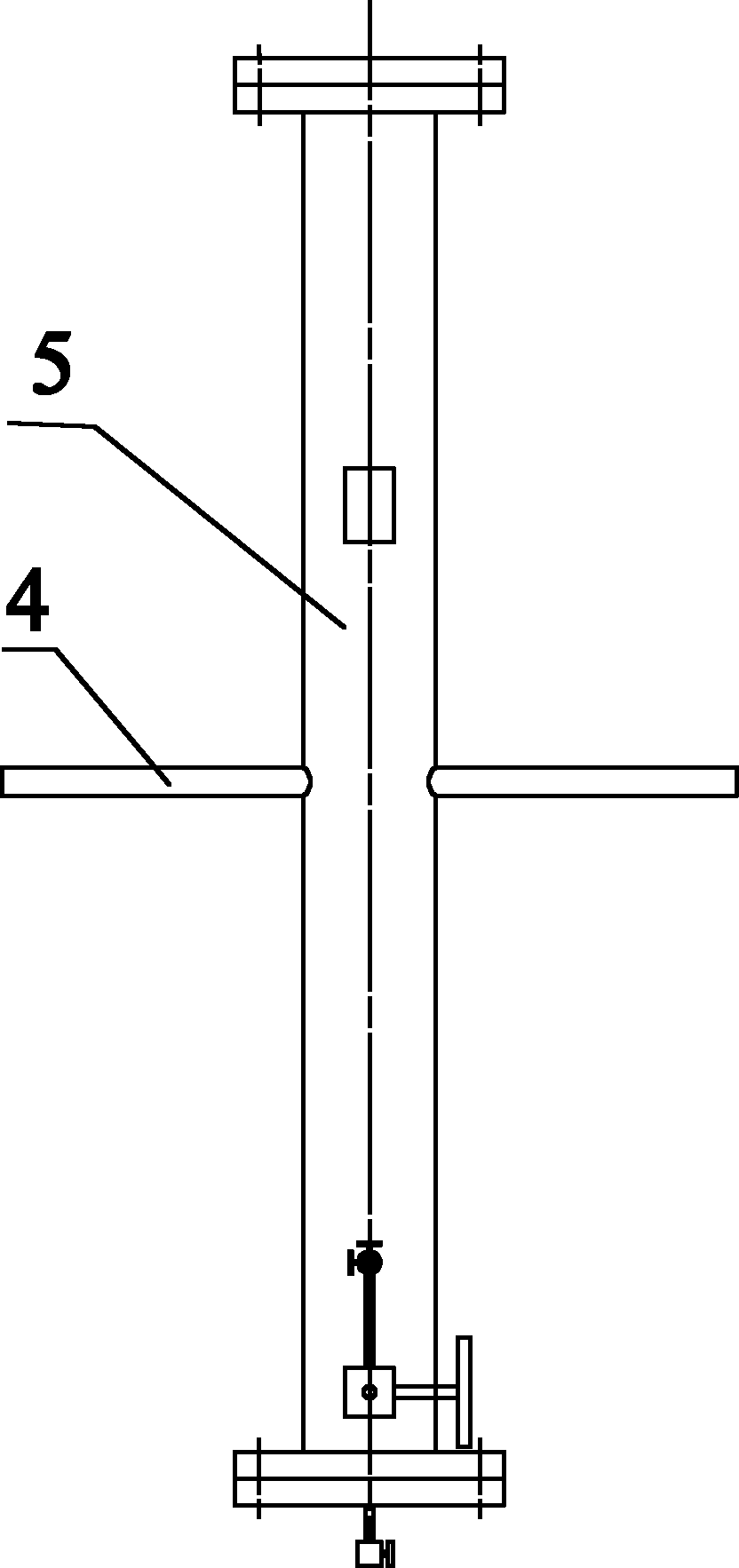

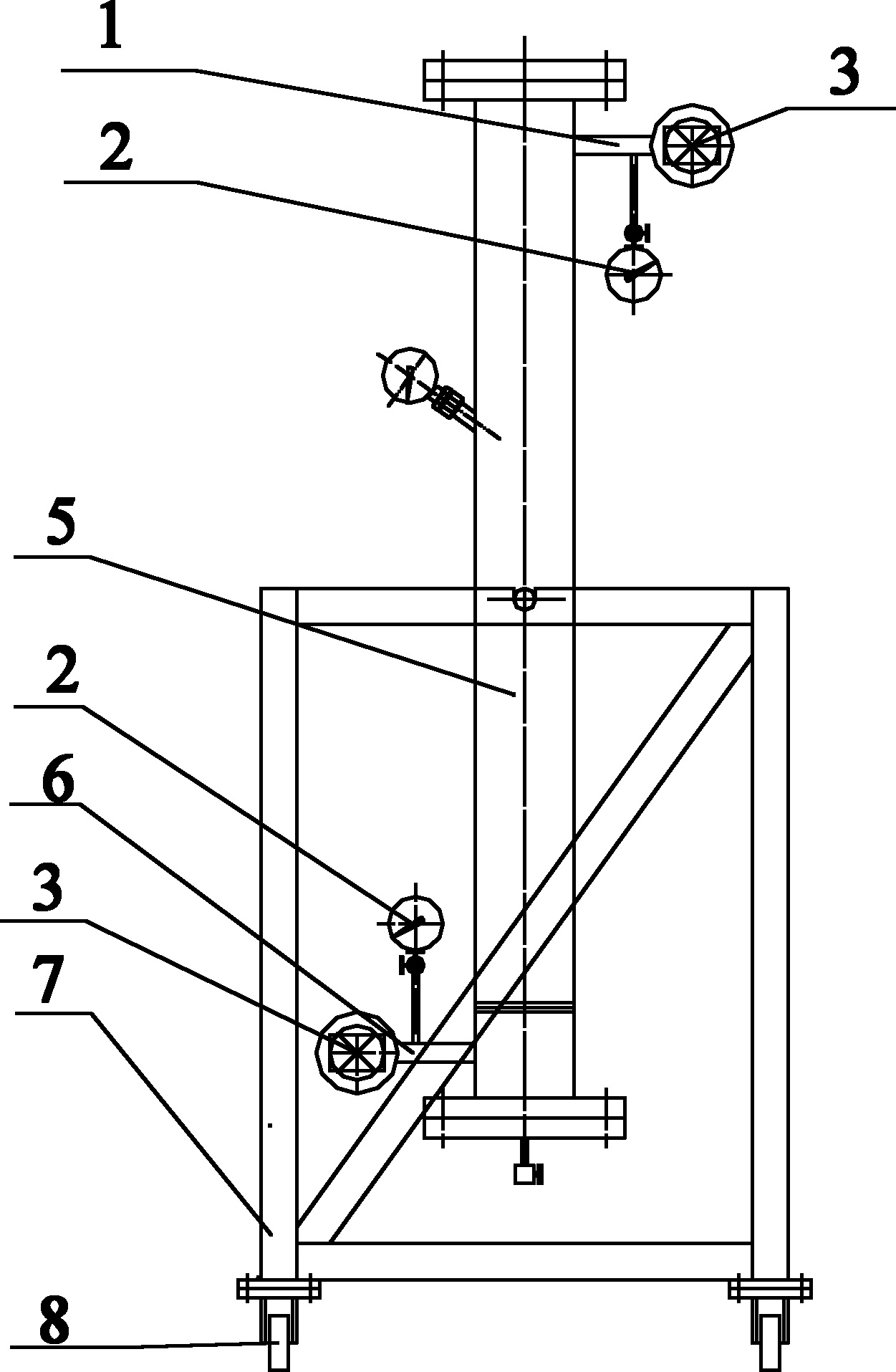

[0021] figure 1 Shown according to the structure of the adsorption tower for testing of the present invention, as shown in the figure, adsorption tower comprises: the tank body 5 that holds adsorbent, for example tank body is elongated cylinder, the support 7 of support tank body and The gas flow control device, the support 7 has a structure arranged on the working surface, such as a rectangular parallelepiped frame, which can be directly or indirectly supported on the working surface, and the tank body 5 is provided with a gas inlet 1 and a gas outlet 6 connected to the gas pipeline . The intake air flow is controlled by a flowmeter, and it runs for a specific time to measure the purificatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com