Selective catalytic reductant and preparation method thereof

A catalyst and selective technology, applied in the field of removing NOx formed by any other combustion process in the industry, and selective catalytic reduction of NOx, it can solve the problems of low performance, low conversion rate, inactivity, etc., and achieve increased hydrothermal stability. , the effect of high NOx reduction characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

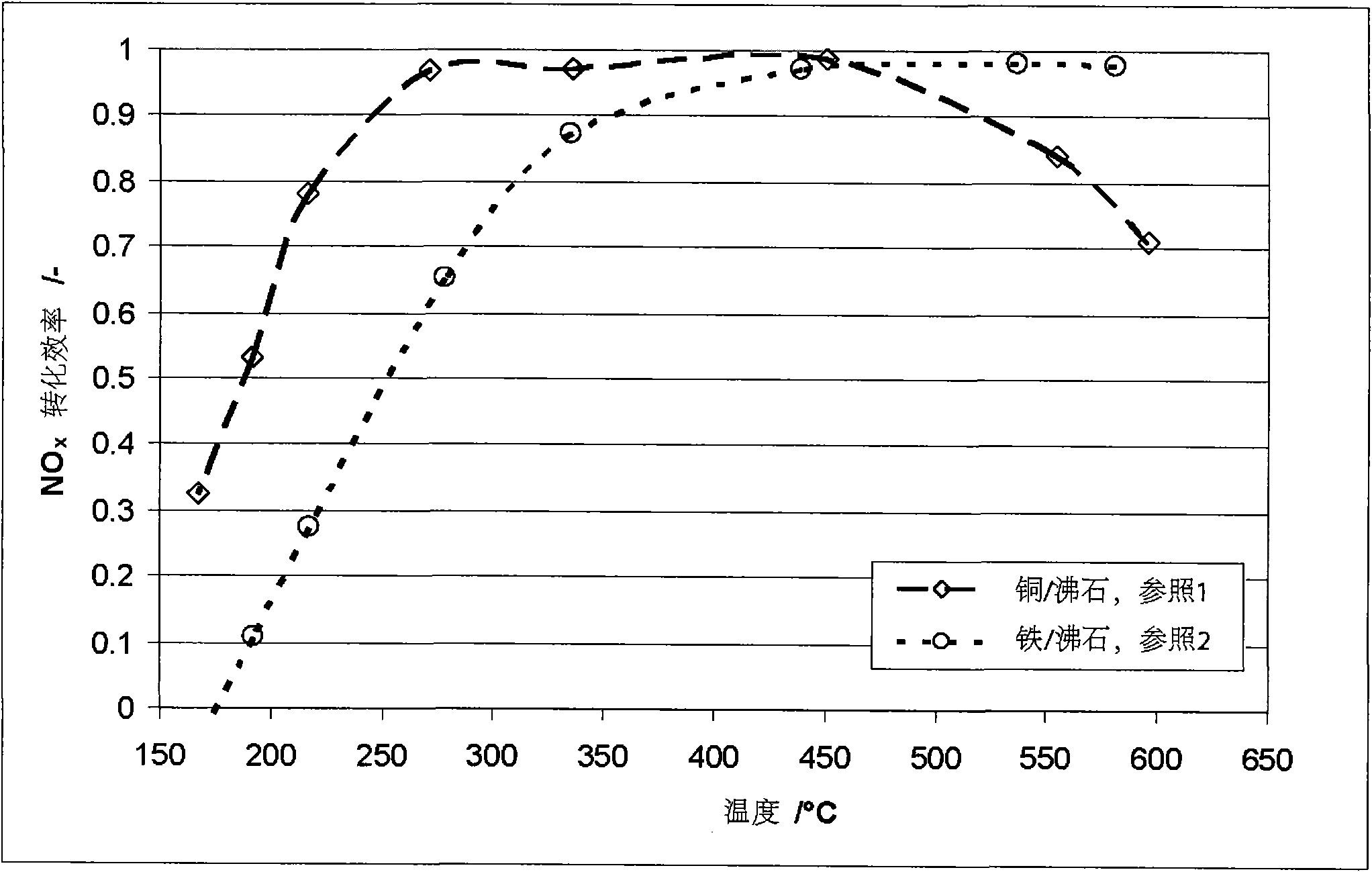

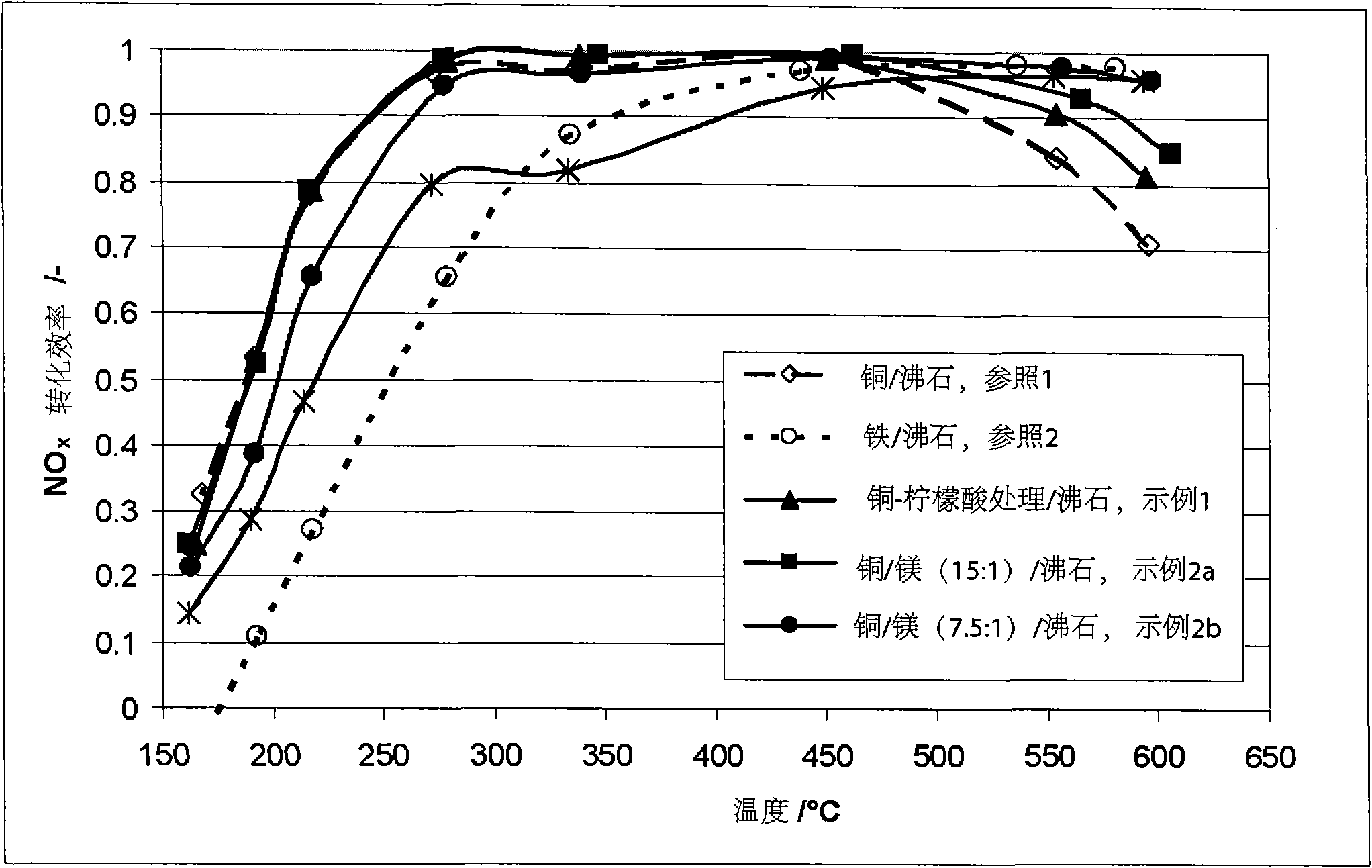

[0069] Commercial SCR catalysts known to react NOx with ammonia (based on copper / zeolite or iron / zeolite, where the zeolite is ZSM5) have different activities and are able to efficiently convert NOx to nitrogen only within a restricted temperature range. Their general properties are shown in figure 1 , using only NO (nitrogen monoxide) as the NOx source and NH 3 / NO ratio α = 1.2, using a small excess of ammonia. The data obtained represent typical characteristics of copper (copper / zeolite, ref 1) and iron (iron / zeolite, ref 2) of current commercial technology. as from figure 1 It can be seen that the performance of copper-SCR is good in the low temperature range starting from 175-200 °C, even using only NO without adding NO 2 Allowing for a NOx conversion close to 70% at 200°C. Copper-SCR catalysts have excellent levels of NOx conversion (which approach 100% NOx reduction) in the moderate temperature range of 200-400°C, but NOx conversion decreases at temperatures above...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com