Non-drive type rear axle for automobile

A non-drive, rear axle technology, applied in the direction of axles, wheels, vehicle parts, etc., can solve the problems of unsuitable for commercial cargo, high cost, complex structure, etc., to ensure the overall strength and reliability requirements, improve strength and strength , to ensure the effect of safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

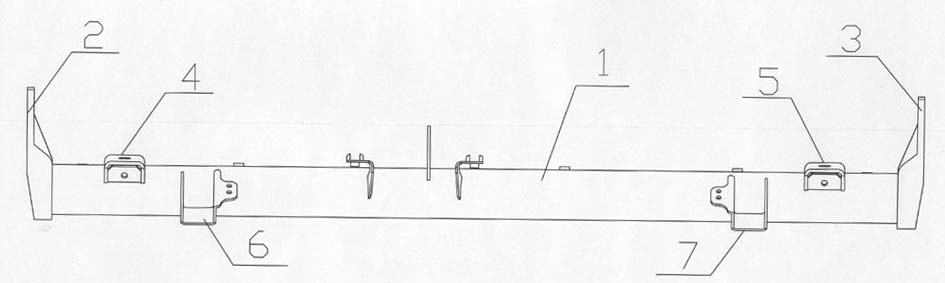

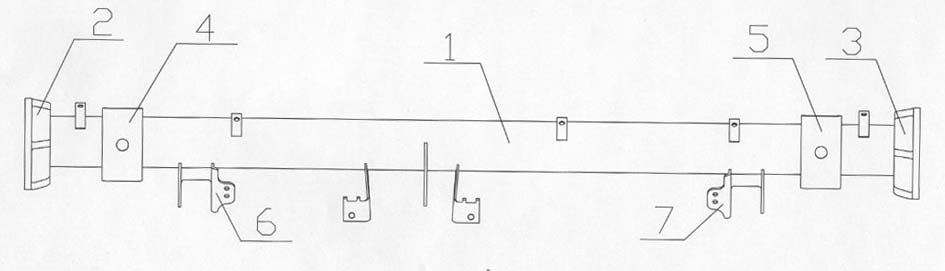

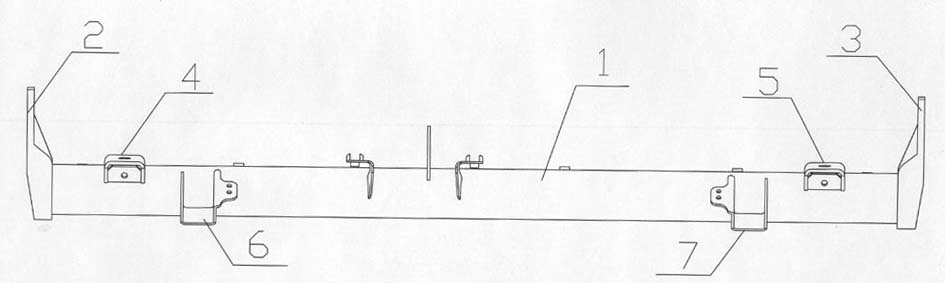

[0011] Such as figure 1 , 2 As shown, the non-driven rear axle used for automobiles according to the present invention includes a rear axle tube 1, and left and right rear wheel hub axle seats 2, 3 are symmetrically arranged upwards on both sides of the rear axle tube 1. Left and right leaf spring seats 4,5 and left and right rear shock absorber lower seats 6,7 are symmetrically arranged in turn on the rear axle tube 1 close to the left and right rear hub axle seats 2,3. The left and right leaf spring seats 4, 5 are fixedly connected above the rear axle tube 1 through a group of arc-shaped plates matching the outer arc surface of the rear axle tube 1 .

[0012] In order to enhance its rigidity and strength, the rear axle tube 1 is made of seamless steel pipe, replacing the original stamped and welded axle housing; Above, the leaf spring installed on it is arranged above the rear axle tube 1, which increases the height of the roll center of the rear axle suspension, thereby r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com