Multifunctional stress-resistant vermifuge biological organic fertilizer and preparation method thereof

A bio-organic fertilizer, multi-functional technology, applied in fertilizer mixtures, fertilization devices, applications, etc., to achieve the effect of improving soil and supplementing nutrients for crops

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

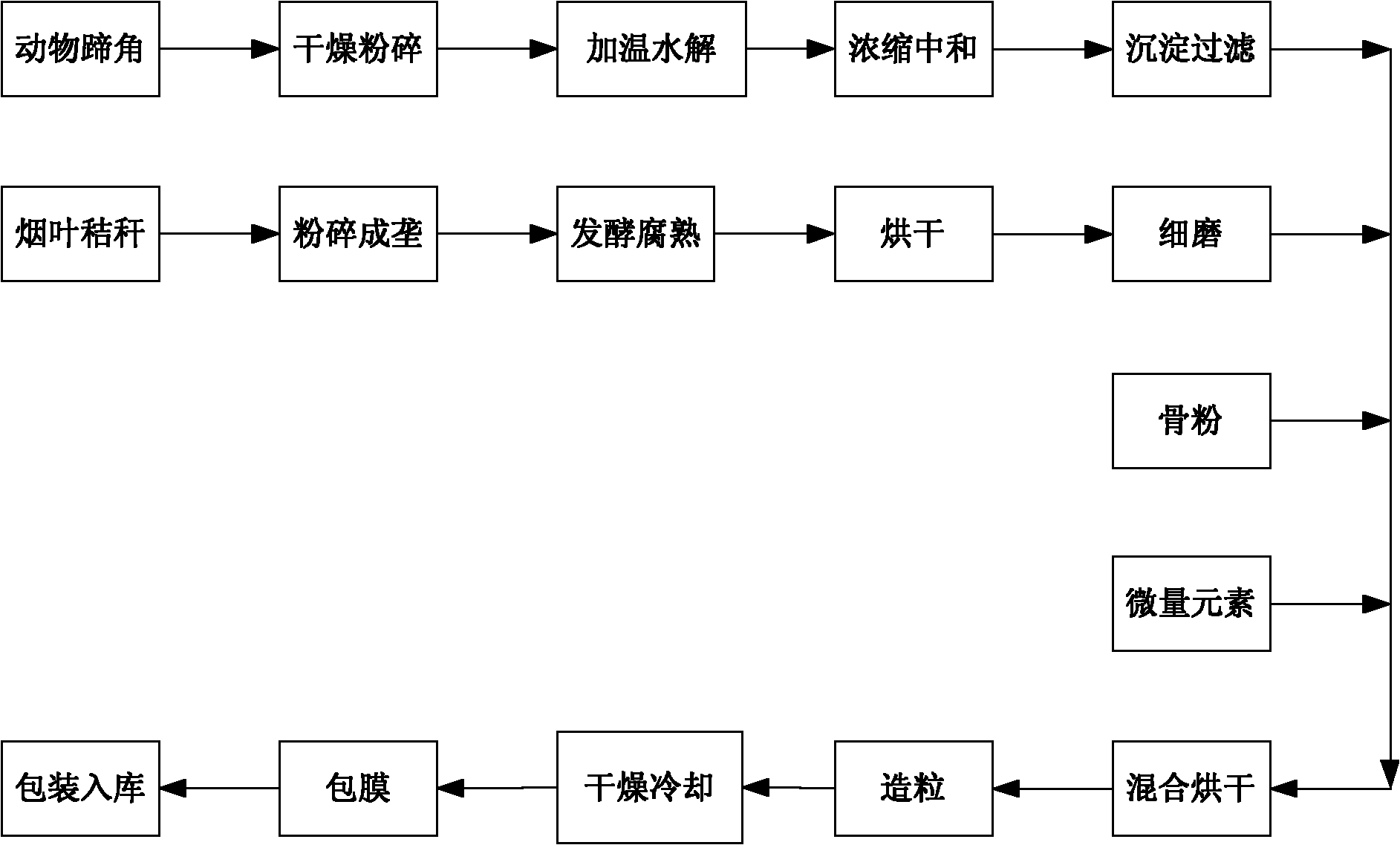

Method used

Image

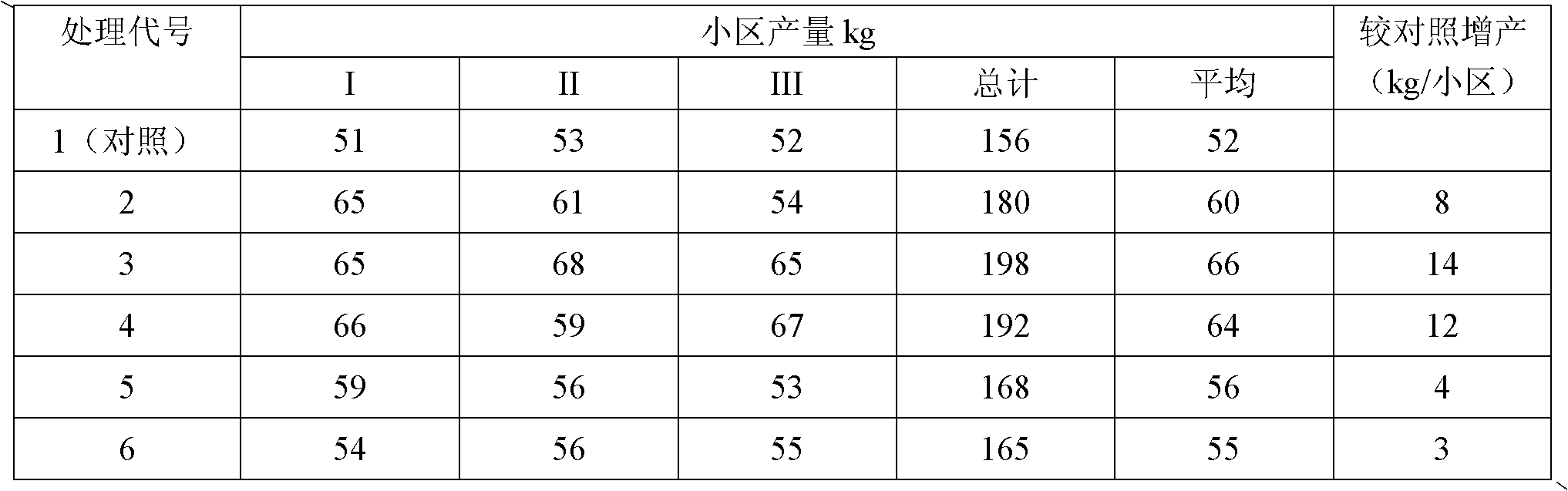

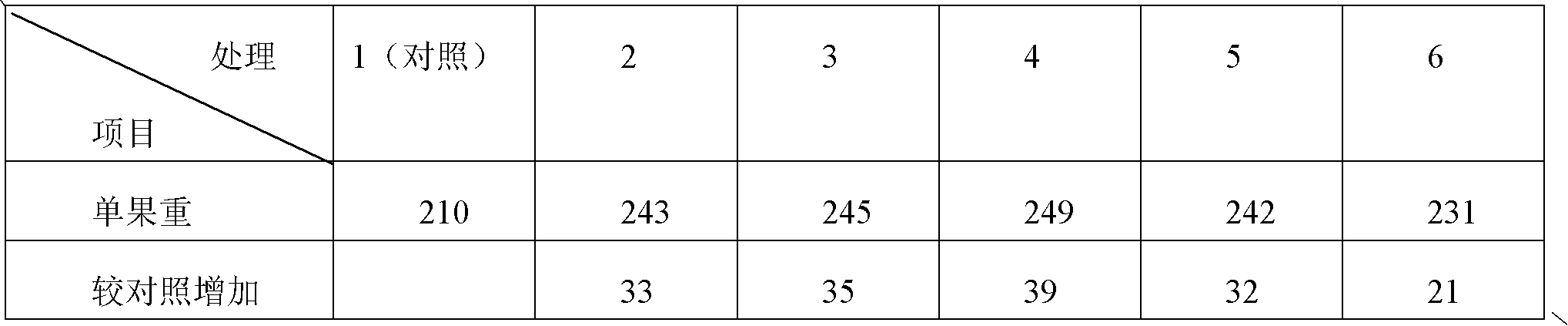

Examples

Embodiment 1

[0059]Before preparation, select materials according to the ratio provided in formula 1. Take 50kg of tobacco stalks, 46.5kg of animal hoof horns, 3kg of bone powder and 0.5kg of trace elements. After the selection of materials, start the preparation:

[0060] 1] Preparation of amino acid stock solution

[0061] 1.1] After crushing the dry and clean animal hoof horns, add appropriate amount of acid and water to adjust the pH value to 5.5, at 60°C, the pressure is 0.40kg / cm 2 Place it under the condition for 48 hours, make it completely hydrolyzed, and obtain the animal hoof horn hydrolyzate;

[0062] 1.2] Cool down the raw material that is completely hydrolyzed after step 1.1] to 40°C, then concentrate in a vacuum environment to 2.0 times the concentration of the animal hoof horn hydrolyzate, then neutralize, precipitate, and filter in sequence to obtain amino acids stock solution;

[0063] 2] Bacterial treatment of tobacco straw

[0064] 2.1] After the tobacco stalks are p...

Embodiment 2

[0069] Before preparation, select materials according to the ratio provided in Formula 3. Take 70kg of tobacco stalks, 26.5kg of animal hooves, 3kg of bone powder and 0.5kg of trace elements. After the selection of materials, start the preparation:

[0070] 1] Preparation of amino acid stock solution

[0071] 1.1] After crushing the dry and clean animal hoof horns, add appropriate amount of acid and water to adjust the pH value to 5.8, at 100°C, the pressure is 3.9kg / cm 2 Place it under the same conditions for 36 hours to make it completely hydrolyzed, and obtain the hydrolyzate of animal hoof horn;

[0072] 1.2] Cool down the raw material that is completely hydrolyzed after step 1.1] to 0°C, then concentrate in a vacuum environment to 1.5 times the concentration of the animal hoof horn hydrolyzate, then neutralize, precipitate, and filter in sequence to obtain amino acids stock solution;

[0073] 2] Bacterial treatment of tobacco straw

[0074] 2.1] After the tobacco straw...

Embodiment 3

[0079] Before preparation, select materials according to the ratio provided in Formula 9. Take 61.8kg of tobacco stalks, 37kg of animal hooves, 1kg of bone powder and 0.2kg of trace elements. After the selection of materials, start the preparation:

[0080] 1] Preparation of amino acid stock solution

[0081] 1.1] After crushing the dry and clean animal hoof horns, add appropriate amount of acid and water to adjust the pH value to 6.0, at 140°C, the pressure is 2.83kg / cm 2 Place it under the same conditions for 24 hours to make it completely hydrolyzed, and obtain the hydrolyzate of animal hoof horn;

[0082] 1.2] Cool the raw materials that are completely hydrolyzed after step 1.1] to 20°C, then concentrate in a vacuum environment to 1.5 times the concentration of the animal hoof horn hydrolyzate, then neutralize, precipitate, and filter in sequence to obtain amino acids stock solution;

[0083] 2] Bacterial treatment of tobacco straw

[0084] 2.1] After the tobacco straw ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com