High-gloss scratch-resistant and antistatic ABS (acrylonitrile-butadiene-styrene) alloy

An anti-static and scratch-resistant technology, applied in the field of ABS alloys, can solve the problems of recycling, poor scratch resistance, scrapping, etc., and achieve the effects of easy operation of the preparation process, good scratch resistance and broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

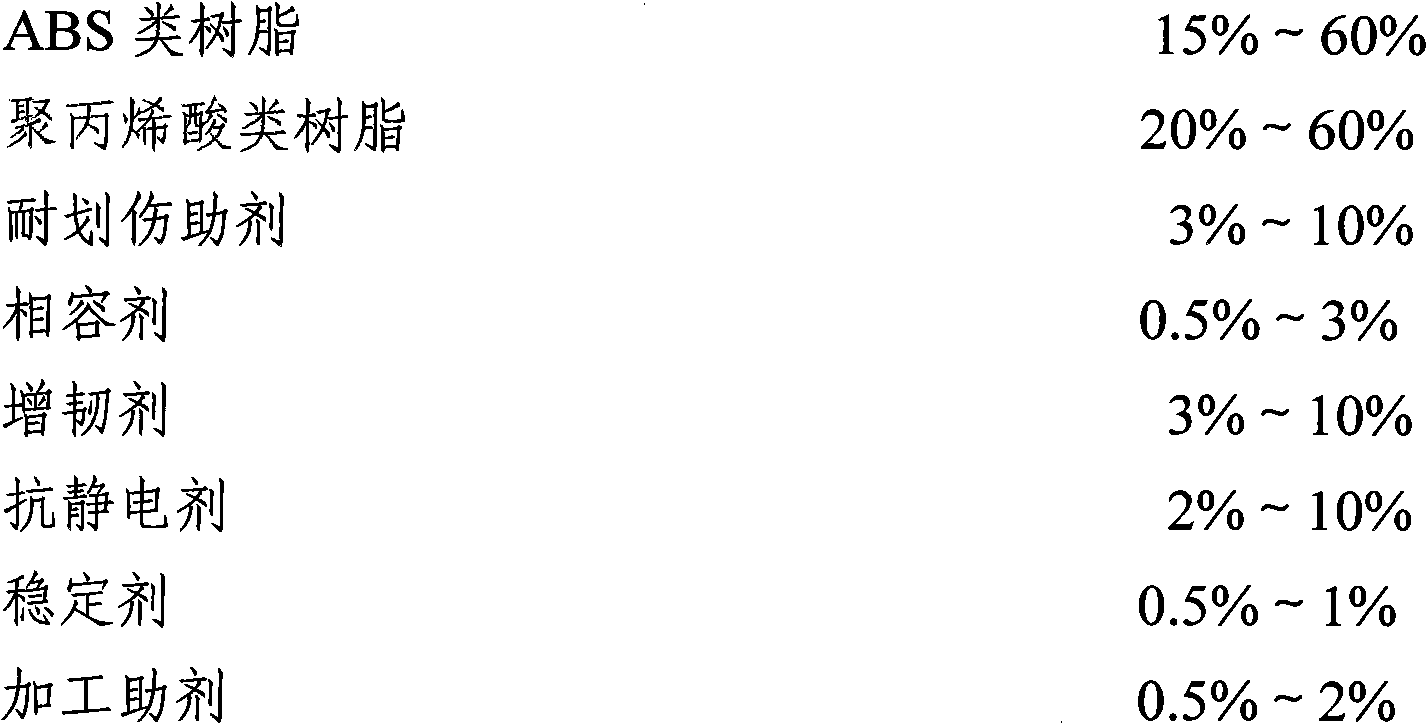

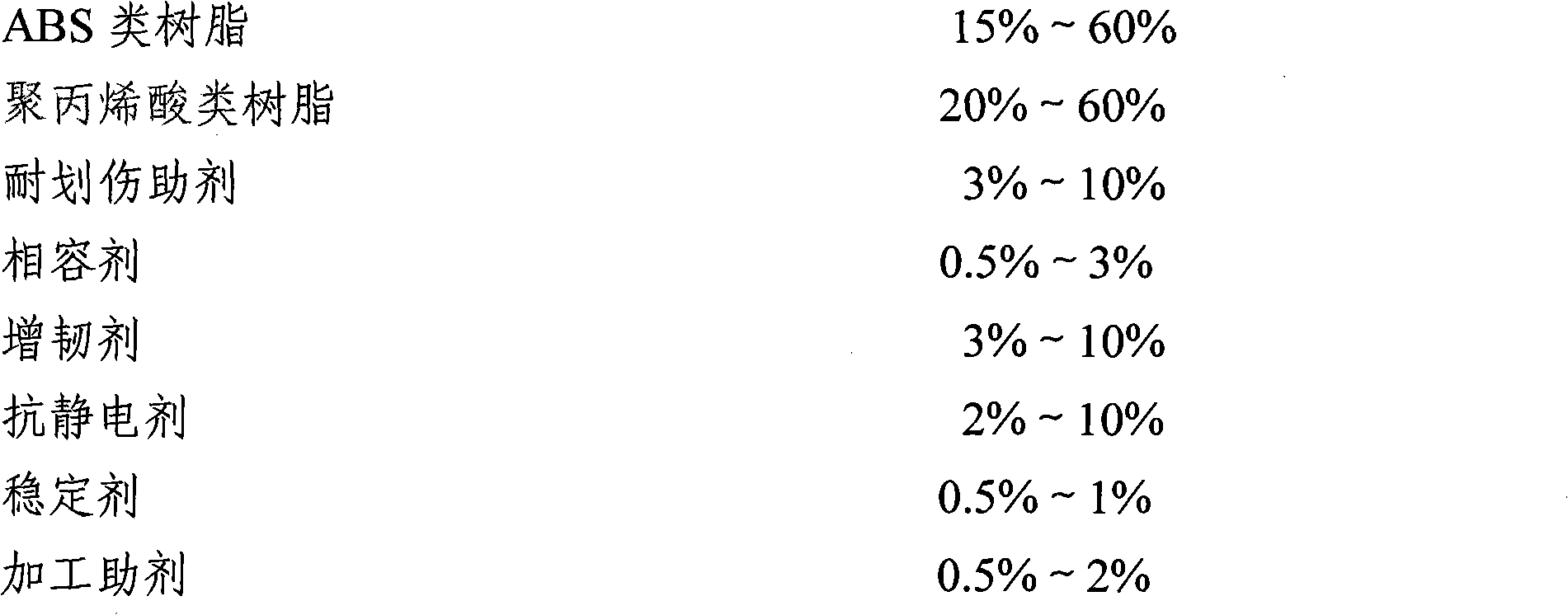

[0025] First ABS resin, polyacrylic resin, anti-scratch auxiliary agent, compatibilizer, toughening agent, antistatic agent, stabilizer and processing aid are according to proportioning (the specific proportioning of each embodiment is shown in Table 1) shown) into a high-speed mixer to mix evenly, and then the above-mentioned mixture is fed into a twin-screw extruder through a feeder with precise metering, and then mixed, extruded, drawn, cooled, and pelletized; where: The length-to-diameter ratio of the screw extruder is 32-40, the screw temperature of each section is 180-220°C, and the screw speed is 100-600 rpm.

[0026] Table 1. The specific proportioning of each composition in each embodiment

[0027] composition

Example 1

Example 2

Example 3

Example 4

ABS resin 【ABS resin】

15

35

45

60

PMMA resin [polyacrylic resin]

60

44

32

20

Trimethoxysilane Oligomer 【Scratch Resistance Additive】

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com