Wonder fabric

A fabric, textile technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

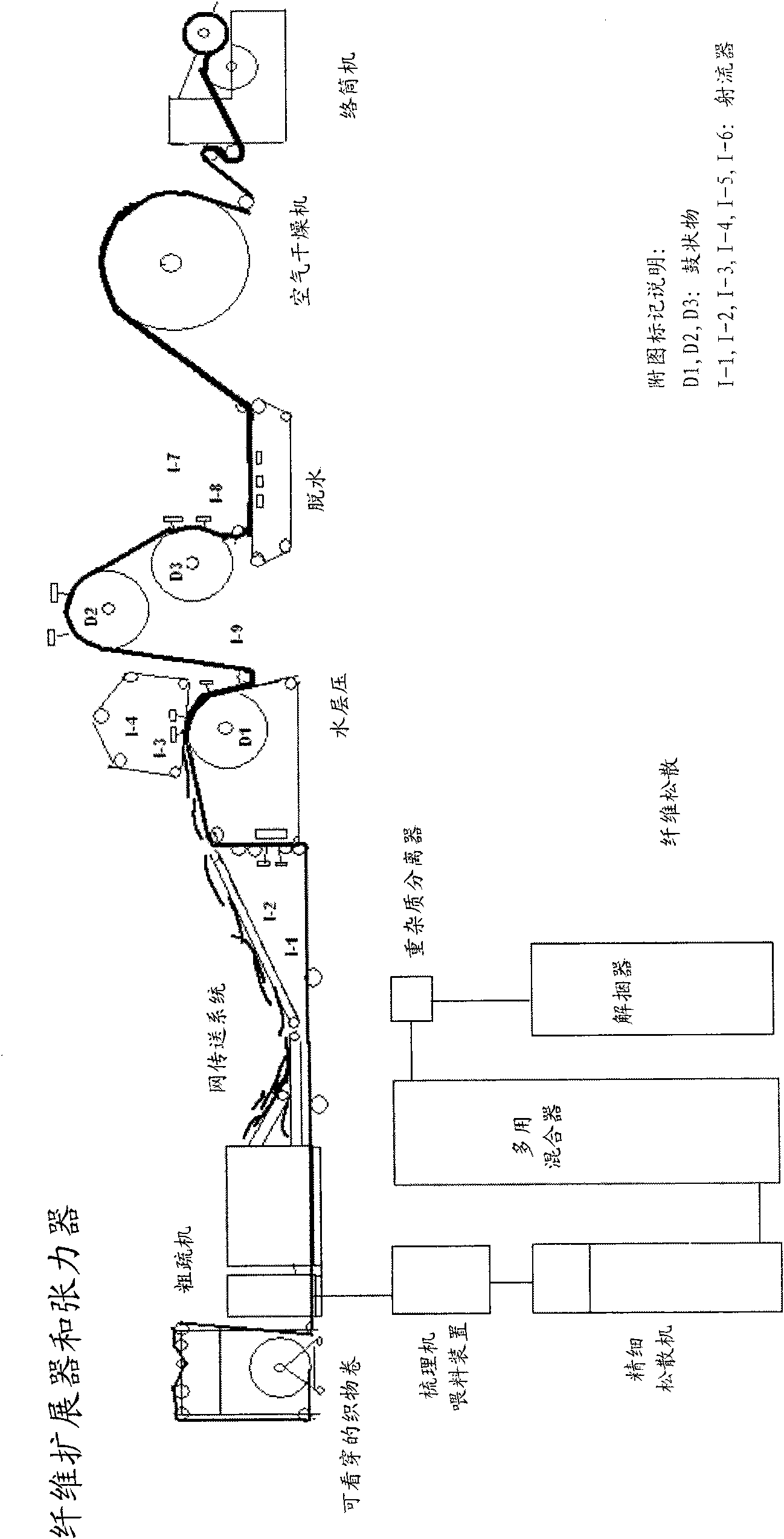

Method used

Image

Examples

Embodiment 1

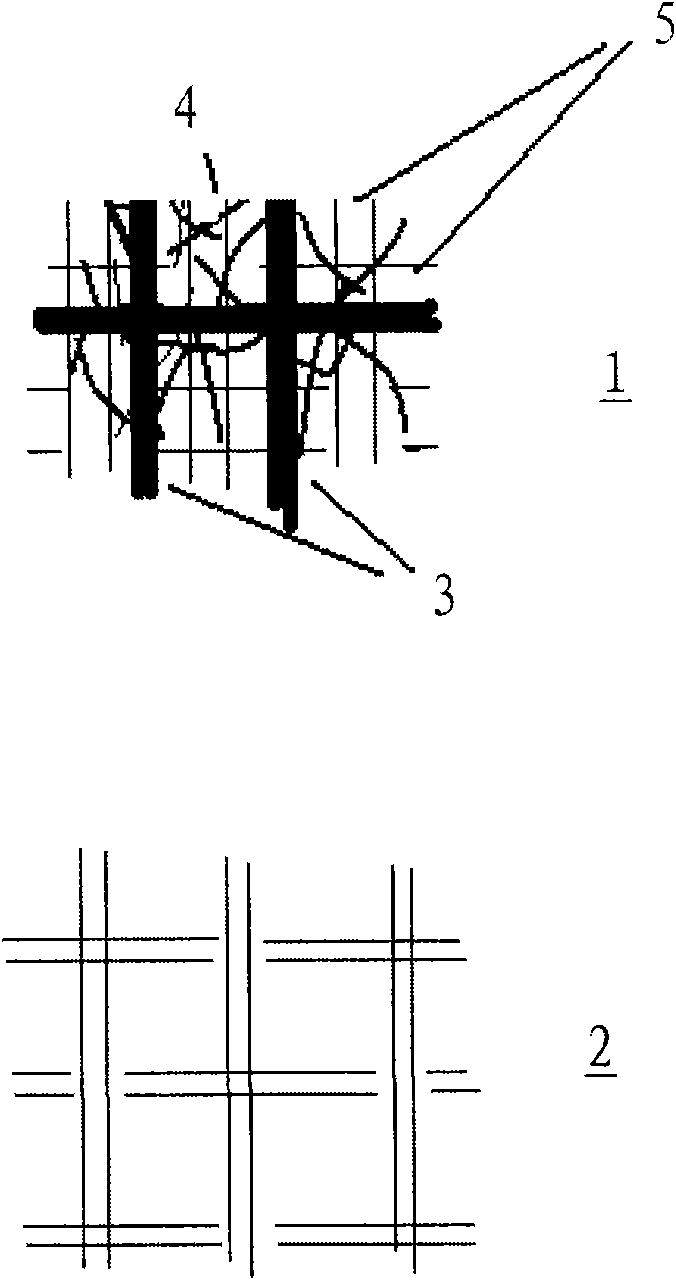

[0123] Example 1: 0.1 mm diameter jets arranged in a single row of 23 jets per inch (23 jets / inch) impinge on the web at a pressure of 50 bar (bar), thereby establishing a level of fiber entanglement such that the width of the web in the machine direction is The tensile breaking load was 4.5 N / m, and the tensile breaking load in the transverse web width was 1.7 N / m.

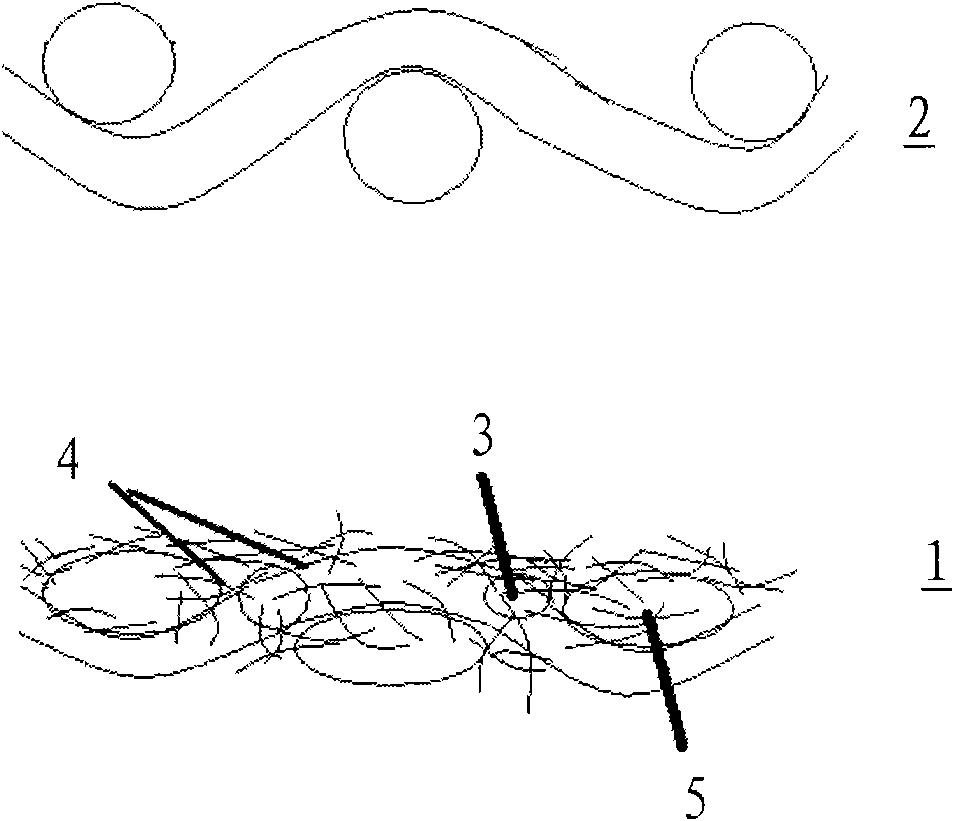

[0124] The web is then subjected to jets of water, the parameters of which are set to form pseudo-yarns on the surface of the textile substrate. In this case, the textile substrate acts as a support for the fiber web. The textile base guides and facilitates the rolling of the fibers of the web so that these fibers entangle with each other and form pseudo-yarns.

Embodiment 2

[0125] Example 2: A textile substrate with a fiber cover factor of 14 was laid with a cotton fiber mesh and the entire structure was subjected to high pressure water jets (types of jets described as 0.1mm / 23jets / inch, 0.1mm / 40jets / inch, and 0.1mm / 40jets / inch ), causing fiber rolling to be maximized and formed as Figure 4 Pseudo-yarn shown, with very few filaments on the bottom of the textile substrate.

[0126] The above phenomena are also influenced by fiber properties such as polymer, fiber length, stiffness, diameter and surface friction. The properties of the web (eg fiber orientation, fiber personalization) also influence the above phenomena.

[0127] The structure is then subjected to at least one high pressure water jet. The fibers of the false yarn are entangled with the yarn fibers of the textile substrate. The water jet parameters are selected according to the balance between strength and product hardness.

Embodiment 3

[0128] Example 3: 80g / m 2 Textile base and 35g / m 2 The pseudo-yarn structure, when they are subjected to high-pressure water flow arranged in a single row with a jet diameter of 0.1mm, makes the anti-pilling rate 5.0 and makes the fiber hardness suitable for plain cloth applications.

[0129] Due to the various properties of textile fabrics meant for home textiles and apparel textiles, the first and most important property for any consumer is the appearance of the fabric, followed by the feel. Again it's strength and durability. Attributes such as antimicrobial, odor kill, and fire retardancy are becoming more and more important as time changes and safety and hygiene awareness increases.

[0130] On the other hand, cost is also an important consideration. Those products that achieve the desired appearance and attributes at nominal cost will have a sales guarantee. This is called value for money.

[0131] As mentioned above, raw material costs are the largest of all cost...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com